Crystalliser

Crystalliser is our new printer control software with significantly enhanced features that provide benefits not available with the older Photonics software.

Studio

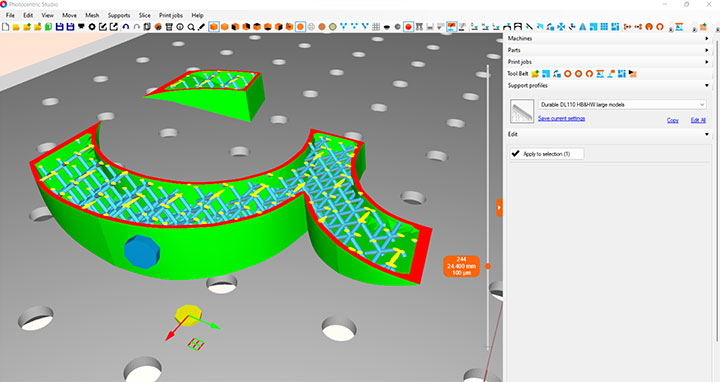

Photocentric Studio is our support and slicing software designed to be simple to use, intuitive and powerful. Photocentric studio is compatible with most CAD formats and includes a suite of tools to support a variety of industries and levels of experience.

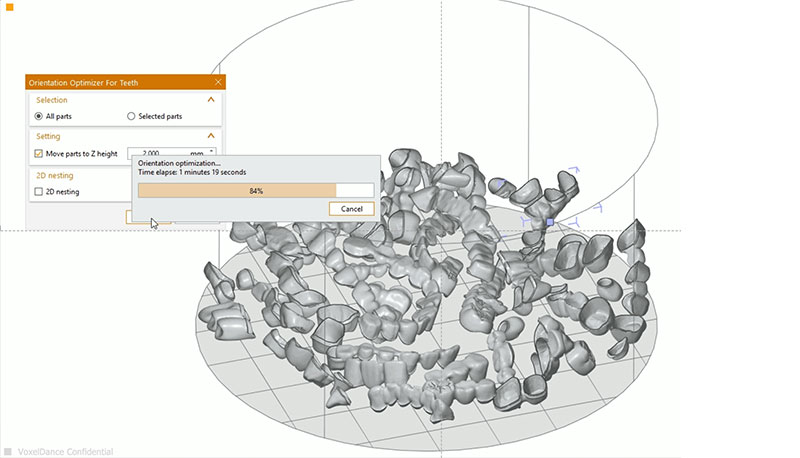

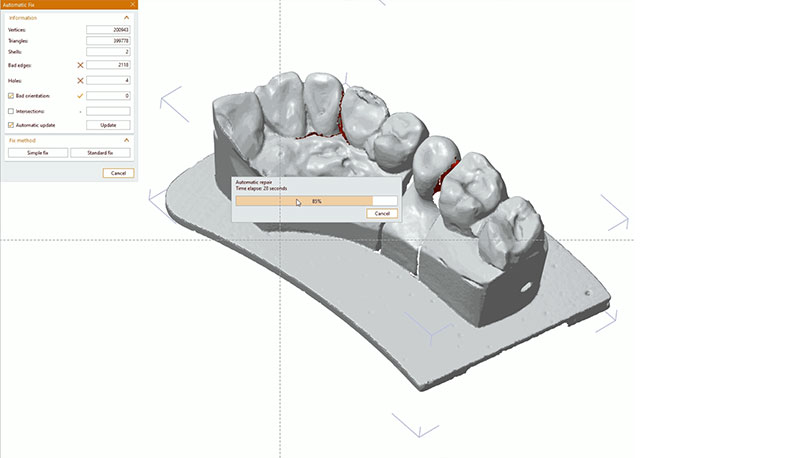

Voxel Dance

Voxel Dance Additive is an alternative to Photocentric Sudio that is better suited to handling large files and has an array of powerful 3D printing support structures allowing rapid print build preparation and delivers unparalleled print success.

Conductor

Photocentric conductor is our farm management software and also the brain inside JENI. It uses a fully digitally defined process and organises production across multiple machines. It helps optimise and streamline production with AI process engineering and operator management.

Conductor

Photocentric conductor is our farm management software and also the brain inside JENI. It uses a fully digitally defined process and organises production across multiple machines. It helps optimise and streamline production with AI process engineering and operator management.

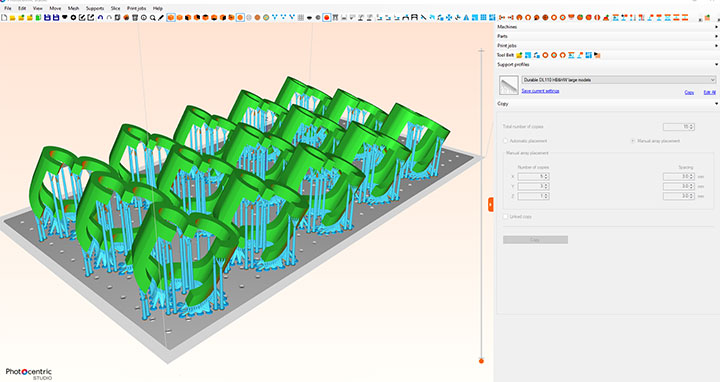

Photocentric Studio

Gamechanger for additive manufacturing

Photocentric Studio is our support and slicing software designed to be simple to use, intuitive and powerful. Photocentric studio is compatible with most CAD formats and includes a suite of tools to support a variety of industries and levels of experience.

Increased productivity

Photocentric Studio offers automated batch processing and part nesting to maximise platform use. The software also provides automatic and manual 3D model orientation, translation, scaling, copying and mirroring. Rapid processing of large files and sophisticated features make this the software of choice for industry professionals.

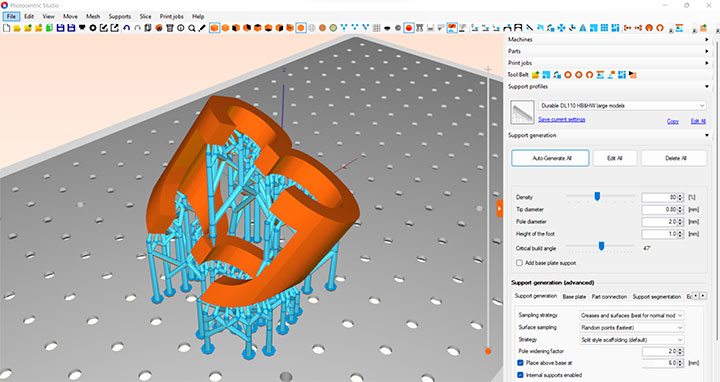

Optimised auto support generation

Photocentric Studio delivers an optimised auto support generation algorithm to minimise software preparation time. The extremely fast function uses superfast multiprocessing to provide ultimate automation. The software is also loaded with pre-set support profiles based on the resin type and part geometry.

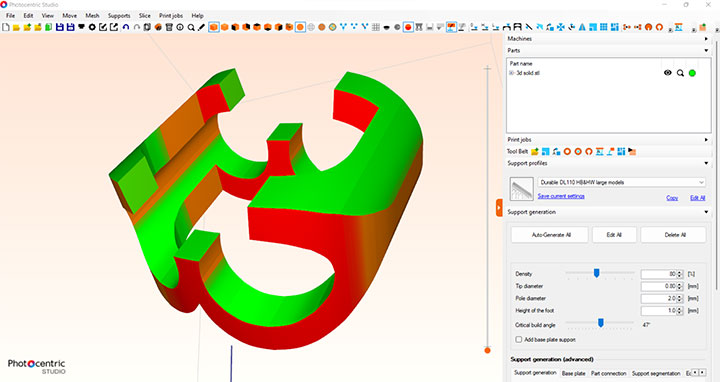

Auto detection of critical support areas

The automatic analysis tool identifies areas where support structures are required. Photocentric Studio also provides multi-platform support for large print volumes.

Drain holes, hollowing and infill of models

Photocentric Studio allows for models to be optimized with drain holes, hollowing, and infills to reduce resin use.

Licence

A Photocentric Studio licence is a perpetual which can be installed on two computers. If your Photocentric Studio licence on your PC has been lost or no longer accessed on your PC then you can buy a licence reset to reobtain your licence.

Photocentric Studio

Photocentric Studio Licence Reset

Minimum system requirements

– Operating System Windows 7, 8 or 10

-Minimum 2.0 Ghz processor speed 2 cores. Recommended 4 cores

– GPU capable of opening opengl version 3.0 or higher. E.g Nvidia GEForce 1050 or higher

– .net framework version 4.0

– 64bit system: minimum 2GB of RAM, recommended 4GB

– 32bit system: minimum 1GB of RAM, recommended 2GB

You can run the software using macOS by using a Virtual Workstation with Windows installed on it.

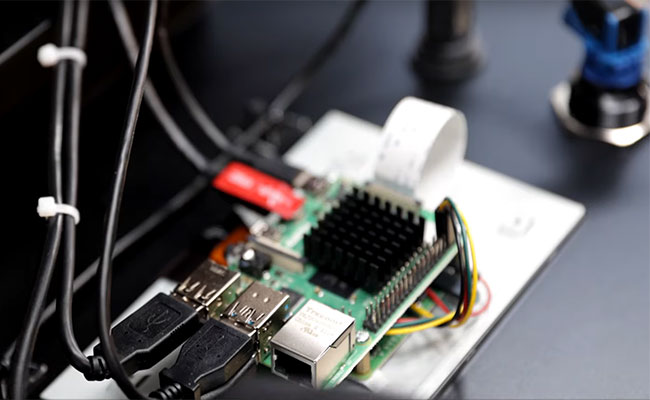

Crystalliser

Our new printer control software

Crystalliser is our new machine control software which is written from the ground up to allow our machines to process commands faster than ever before whilst allowing for even finer and more reliable control over your parts. Crystalliser has been designed for Industry 4.0, and it has automation, networking and flexibility at its heart. Going forward, Crystalliser will be the backbone of Photocentric’s hardware line-up. We hope you enjoy the new software and the experience of using our machines.

First time install

If the machine is not yet running Crystalliser, please follow the guide below. This process will only need to be done once. Future updates will use the normal method.

Crystalliser is currently only available for first time install for LC Opus and LC Magna V.2.

1. This process will delete any files on the machine already. Ensure copies of all important files are backed up.

2. Download the corresponding .img file for the machine from here

3. Switch off and unplug the power from the machine.

4. Remove the microSD card from the machine. Ensure the power cable is unplugged first and follow the steps detailed in these videos to access the microSD card.

If the machine is already running Crystalliser, please download the latest update file, load it onto the machine and press software update.

5. Download and install an SD card flasher such as Balena Etcher from here

6. Follow the instructions in the flashing software to write the .img file to the MicroSD card.

7. Safely eject the MicroSD card from your PC.

8. Once complete, replace the MicroSD card into the machine and put the panel back.

9. Power on the machine. Follow the on-screen instructions to input the machine serial number into the software. It is crucial this is done correctly.

10. Follow the normal update process to update the machine to the latest version of Crystalliser.

Photocentric Studio – Crystalliser

To fully utilise Crystalliser software, you must install new Printer Profiles in Photocentric Studio.

To install the new crystalliser printer profiles, follow these steps:

1. Go to configuration -> Machine -> Add machines.

2. Select the appropriate printer model from the following options:

– Liquid Crystal Magna V.2 Crystalliser

– Liquid Crystal Magna V.2 Crystalliser – Fast Printing

– Liquid Crystal Magna V.2 Crystalliser – Slotted Platform

– Liquid Crystal Opus Crystalliser

3. After downloading the studio profile, you’ll need to download the PFP converter, which will enable you to convert your CWS files to CRS profile.

Once the printer is updated to crystalliser, it will no longer be able to accept .CWS files.

Crystalliser Release Notes

V2.0.2 - 30/04/24

- Fixed an issue where blank g-code lines from some slicers cause time outs for 3 minutes.

- Improved initial boot up screen for first initialisation.

V2.0.0 - 02/02/24

New features:

- First release of Crystalliser for Magna v.2, Titan, Opus and Opus12K printers.

- Timelapse filming capabilities on all machines.

- We time the timelapse with each layer of the print to create a super smooth motion in the video. At the end of the print, the machine compresses all images into H.264 format and saves it in the files where you can access it.

- To use the time lapse feature, plug a camera into a USB port on the front or back of the machine before turning the machine on.

- The camera needs to be UVC compliant, and it supports up to 1920 x 1080px resolution in portrait mode. The LC Titan comes with a camera pre-installed.

- Important: Do not unplug the camera mid print – it will cause a software crash and the print to fail. If you unplug the camera at any point, please restart the machine.

- Smoother file management, add and remove files as you need.

- New web UI. If using the same network as the machine, simply type in the IP address or the hostname followed by “/” or “./” depending on your network. You can upload/download files, monitor and control the machine remotely.

- New .crs file format which is the native format for crystalliser and adds expansion for planned new features

- *.cws files are still compatible with Crystalliser. You should install the Print File Processor and use the crystalliser machine profiles to create these .crs files. Other Photocentric Studio profiles will work but will take longer to process on the machine.

- Overhauled routines for maintenance and calibration.

- Easier software updates meaning no more removing the SD card. Future software updates will be distributed as a .swu file which can be loaded onto the machine from a USB or the web UI.

- Network management and settings.

- Subpixel rendering for OPUS12K

- The OPUS12K screen has monochrome pixels that think they are Red, Green and Blue but are actually all transparent. By slicing the images wider and then compressing them, enables the correct colour to be displayed in that pixel relative to the spatial location of the coloured subpixel. This enables to resolve at 3x the resolution in one axis.

- REST API for remote monitoring, connection to MES software or wider production ecosystems. For documentation of our API, please contact support@photocentric.co.uk

- More reliable pause, resume and cancel functionality that reduces risk of print failure or defect.

- Support for material level sensing and pumping on LC Titan.

- Log data export for easier service debugging.

- Support for other slicers

- Print File Processor software enables our machines to accept files from Photocentric Studio and Voxeldance Photocentric Edition.

Performance Improvements:

- Rewritten front end in a more efficient architecture creating a much more responsive and refreshed UI

- Faster printing through optimised software timings and streamlined processing

- LC OPUS – 10-15% speed increase

- LC Magna v.2 – 5-10% speed increase

Print File Processor

To make the most of the new software, you need to install our Print File Processor (PFP) software. This will convert your sliced files to .crs to be used by Crystalliser (Windows only).

PFP for Photocentric Studio

Photocentric Studio automatically uses PFP when the Crystalliser machine profiles are used.

PFP for External Slicers

Install the Print File Processor software and use it to convert sliced files from Voxeldance.

Troubleshooting/FAQs

To make the most of the new software, you need to install our Print File Processor (PFP) software.

This will convert your sliced files to .crs to be used by Crystalliser (Windows only).

What is the roadmap for Crystalliser on older machines?

Crystalliser currently is only for 64bit processors, LC Magna V.2 and LC Opus onwards.

We are looking into how best to get crystalliser to run on the older generation of 32bit processors whilst maintaining all the great features it has.

Please do not try to put crystalliser on a Magna V1.

My machine crashes when I unplug the camera.

Please don’t unplug the camera for now. We are working on fixing this.

My printer is running slowly.

This could be due to high RAM usage if the machine hasn’t been restarted in a while. Please try rebooting the machine.

I tried to use the Crystalliser machine profiles on Photocentric Studio, but my files are not correct.

This is likely caused by the PFP not being installed correctly. Please unistall and reinstall the PFP.

Ensure the PFP is installed in the same location as the Photocentric Studio software.

I can’t connect to the web UI.

Make sure you are connected to the same local network as the machine.

You can find the IP address or hostname of the machine on the machine’s UI. On first boot, the hostname is set to the serial number of the machine.

Some browsers need you to put http://<machine-address>/ where “<machine-address>” is the hostname or the IP address of the machine.

You may need to put a period “.” before the last forward slash “/” after the hostname for example: http://my-printer-hostname./

If you are still having issues or have any feedback, please contact support here

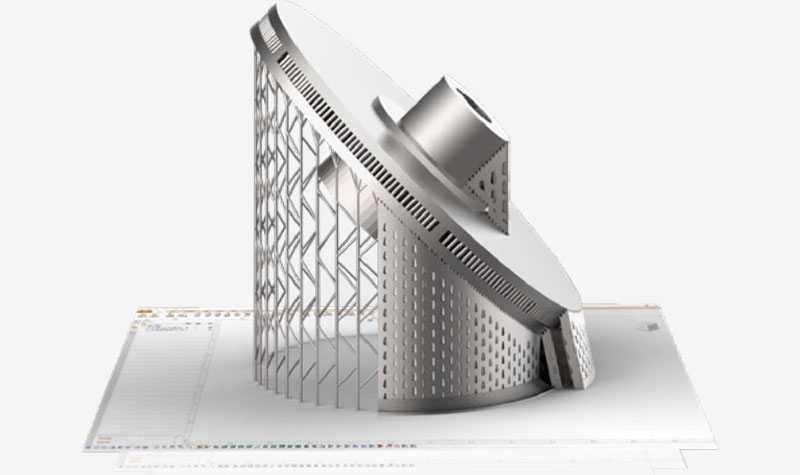

A powerful 3D printing build preparation software

Enables large format printing on Liquid Crystal Titan and Liquid Crystal Magna. The optimised VDK geometry engine and streamlined workflow allows rapid print build preparation and delivers unparalleled print success rates.

Import your file format

Supports nearly all the file formats; CLI Files(*.cli), SLC Files(*.slc), STL(*.stl), 3D Manufacturing Format(*.3mf), WaveFront OBJ Files(*.obj), 3DExperience(*.CATPart), AUTOCAD(*.dxf, *.dwg), IGES(*.igs, *.iges), Pro/E/Cro Files(*.prt, *.asm), Rhino Files(*.3dm), SolidWorks Files(*.sldprt, *.sldasm,*.slddrw), STEP Files(*.stp, *.step) etc.

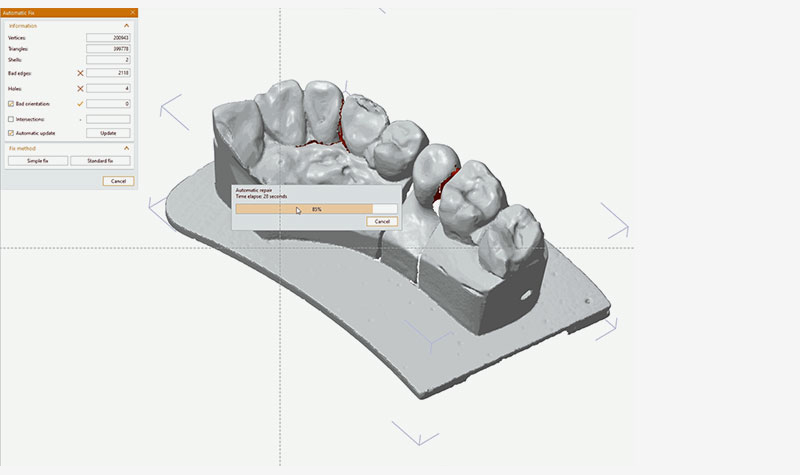

Repair your file

Provides powerful fix tools to create perfect data to deliver perfect printing. Helps identify file errors and automatically repairs them with just one click.

Orientation tools

Unique orientation this reduces manual operation and greatly improves process efficiency and quality assurance.

Nest your parts

Automatically nest your parts rapidly in 2D/3D. It provides multiple placement options including x:y axis orientation, blade direction, and platform layout alignment.

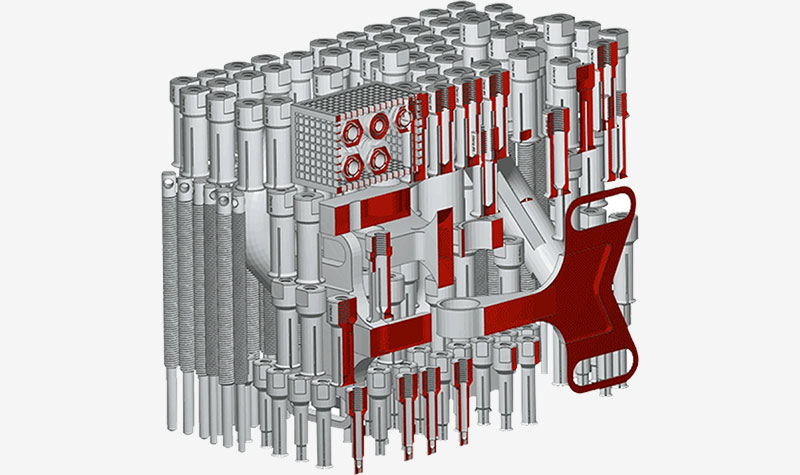

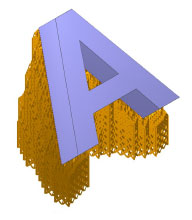

Multiple Supports

Powerful support types that are compatible with Titan’s and Magna’s build process. Support types of bar, point, line, block and smart support.

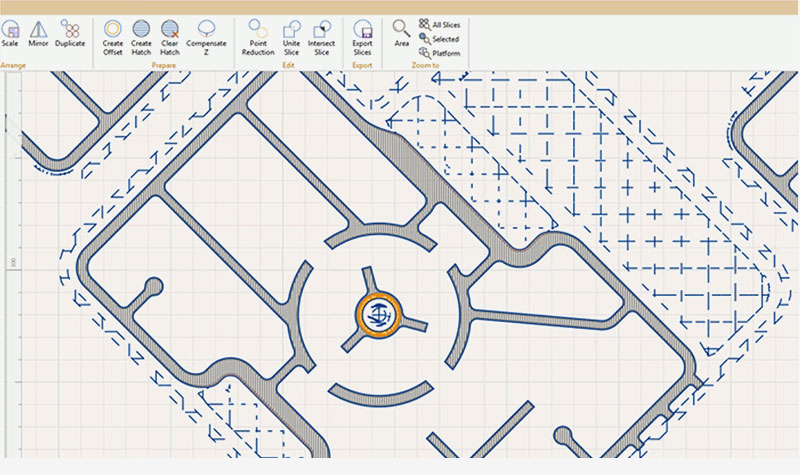

Enhance your Slice Files with Hatches

Generate slices and add hatches with one click, export slice file in multiple formats, including CLI, SLC, PNG, SVG etc. Integrated visualisation interface allows you to easily check slices and hatches.

Support Types

Bar

Volume

Point

Solid

Line

Smart