Liquid Crystal Opus

Large, fast and high-resolution printing

From the inventors of LCD 3D Printing, Liquid Crystal Opus delivers fast, highly accurate prints for a wide variety of industries

Printer

Specifications

Impressive build volume

310 x 174 x 220mm

(12.2 x 6.9 x 7.9’’)

High resolution

81μm pixel pitch delivering outstanding finish

Fast printing

Incredibly fast cure speed of 2 seconds per layer at 50µm layer thickness

Robust and Reliable

Meticulous attention to detail and precision engineered mechanical components deliver outstanding performance.

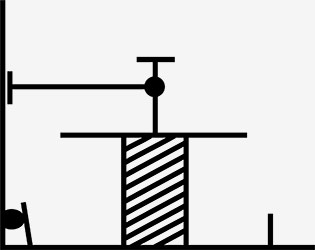

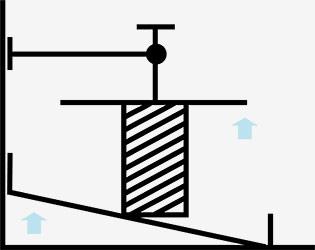

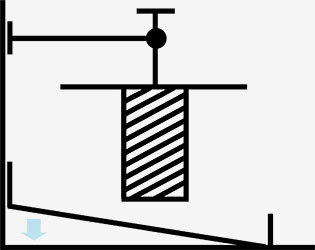

Vat lift technology

Photocentric’s patented peel release technology ‘Vat-Lift’ ensures reliability over large surface area printing

Custom monochrome screen

A unique design supports consistent and reliable high performance

Open source

Operates with all 405nm resins

The machine that lifts

Vat lifts before platform to remove force.

Long lasting, accurate and reliable printer, for dental, research or engineering applications

Intuitive and simple operation. Start printing in minutes, delivered pre-calibrated.

1) Printed layer begins to form.

2) Vat lifts while platform is going up, separating the vat film from the LCD.

3) Vat returns to its original position, ready for the next layer.

Open-source UV 3D printer

Operates with all 405nm resins. Delivers consistent, accurate parts

Use our dedicated range of optimised UV materials or your choice of third-party resins.

Forward AM Ultracur3D® Photopolymers have been validated on our LC Opus 3D Printer

We are pleased to confirm that ten different Ultracur3D® photopolymers are now fully validated and print-ready with LC Opus:

DM 2505, EL 4000, FL 60, RG 35, RG 50, RG 1100, ST 45, ST 45M, ST 1400, ST 80

Henkel Loctite 3D materials have been validated on our LC Opus 3D Printer

We are pleased to confirm that two different Henkel Loctite 3D materials are now fully validated and print-ready with LC Opus:

Loctite 3D 3843, Loctite 3D IND405

Complete printing system

Custom designed wash and cure units to deliver the complete processing solution.

Photocentric Wash 15

Ultrasonic cleaner

Photocentric Wash 15 unit is ideal for removing resin from detailed prints and works with our resin cleaner.

Transfer your platform

Wash 15 accommodates full platform parts up to 300 x 275 x 120mm.

Reduce downtime

Wash 15 can perform 140 cleaning cycles before changing fluid.

15L Capacity

Photocentric Cleaner volume.

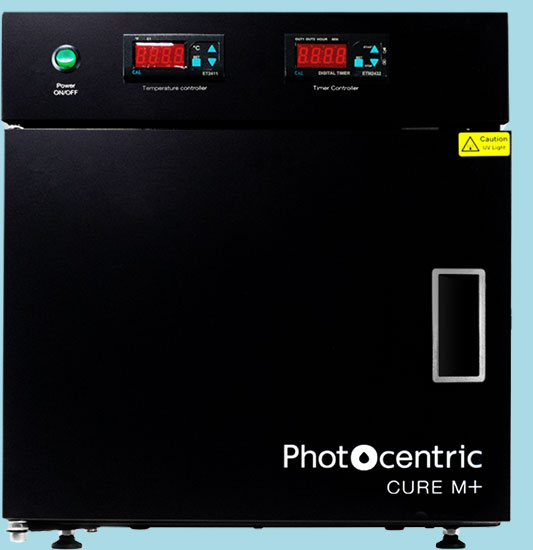

Photocentric Cure M+

Cure parts with heat

Photocentric Cure M+ optimises strength, drying the parts to maximise their material properties.

Large chamber volume

Fits a full Liquid Crystal Opus platform eliminating the need to remove parts beforehand.

Time regulated control

Digital timer control, set the time and leave your prints to cure.

Peak properties

In 20 minutes your printed parts will be dry and strong with maximum material properties.

Complete printing system

Custom designed wash and cure units to deliver the complete processing solution.

Photocentric Wash 15

Ultrasonic cleaning

Photocentric Wash 15 unit is ideal for removing resin from detailed prints.

Transform your platform

Wash 15 accommodates full platform parts up to 300 x 275 x 120mm.

Reduce downtime

Wash 15 can perform 140 cleaning cycles before changing fluid.

15L Capacity

Photocentric Cleaner volume.

Photocentric Cure M+

Cure parts with heat

Photocentric Cure M+ optimises strength, drying the models to maximise their material properties.

Large chamber volume

Cure L2 takes a full Magna platform so you can post-expose on platform.

Time regulated control

Digital timer control, set the time and leave your prints to cure.

Peak properties

In 20 minutes your printed parts will be dry and strong with maximum material properties.

Liquid Crystal Opus Specifications

UV Technology

Light output wavelength 405nm

Build volume

310 x 174 x 220mm

12.2(w) x 6.9(d) x 8.7(h)″

Layer thickness

25 to 100µm

Pixel pitch

81μm | 3.2 thou

LCD screen

14″ 4K 3840 x 2160px

Print speed

18mm per hour at 100µm

0.71″ per hour

7″ touchscreen

Integrated control system

Software

Photocentric Studio

Materials

UV resins, open system

Power Input

110-240 VAC

Printer dimensions

415(w) x 475(d) x 605(h) mm

16.4(w) x 18.7(d) x 23.8(h)”

Connectivity

Wi-Fi, Ethernet, USB 3.0

Printer comparison

Why buy Opus?

High resolution, well-constructed UV LCD printer with screen proven to survive years of use.

IP secure, can operate without internet connection.

Complete processing system with Carbon analysis, TCO, full software and maintenance.

UK manufactured with dedicated highly experienced service department ensuring success.

Liquid Crystal Opus

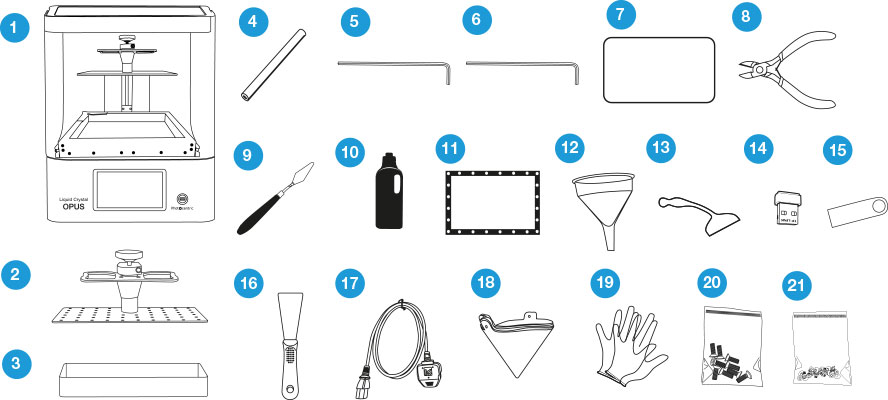

What’s included

1) Liquid Crystal Opus Printer

2) Print platform

3) Resin vat

4) 2x Vat film

5) T25 L shape torx key

6) T10 L shape torx key

7) Silicone mat

8) Cutter

9) Soft spatula

10) 1kg UV DLP Hard black & UV LCD Dental Model white resin

11) 2x Vat gaskets

12) Funnel

13) Vat cleaning tool

14) Wi-Fi dongle

15) 32GB USB

16) Scraper

17) Power cable

18) 5x Paper resin filters

19) 1x Pair of gloves

20) Vat cleaning foam mat

22) 20x M3x4 torx screws

23) 20x M5x10 torx screws

12 months warranty included as standard

Dental Models

(22 per platform)

Layer Thickness – 50μm

(Over 95% of scanned data within +/- 100µm)

Print Time – 1hrs 57 minutes

Weight – 342g (Full platform)

Material – Dental Model Grey

Turbine

(1:1 ratio internal compressor turbine)

Layer Thickness – 50μm

(Over 95% of scanned data within +/- 100µm)

Print Time – 19 hrs

Weight – 281g

Material – DLP High Tensile Grey

Hairdryer

(1:1 ratio)

Layer Thickness – 50μm

(Over 95% of scanned data within +/- 100µm)

Print Time – 19 hours

Weight – 186g

Material – DLP Hard Black

Dental Models

(22 per platform)

Layer Thickness- 50μm

(Over 95% of scanned data within +/- 100µm)

Print Time- 1hrs 57 minutes

Weight- 342g (Full platform)

Material- Dental Model Grey

Turbine

(1:1 ratio internal compressor turbine )

Layer Thickness- 50μm

(Over 95% of scanned data within +/- 100µm)

Print Time- 19 hrs

Weight- 281g

Material- DLP High Tensile Grey

Hairdryer

(1:1 ratio)

Layer Thickness- 50μm

(Over 95% of scanned data within +/- 100µm)

Print Time- 19 hours

Weight- 186g

Material- DLP Hard Black