3D Printing in Space

CosmicMaker

The unique advantages that LCD 3D printers provide have made it the dominant technology in resin printing, but their advantages are even greater in hostile environments, such as ships, war and in space.

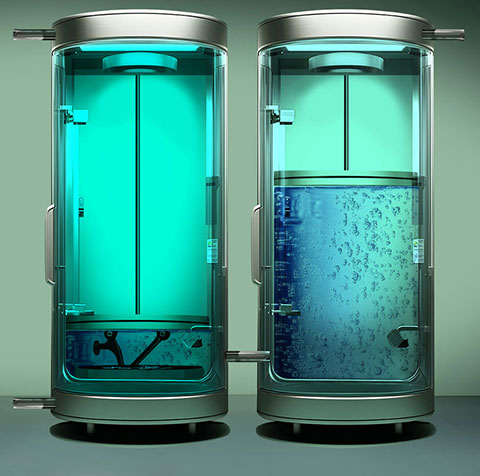

With ESA support, Photocentric has invented and patented CosmicMaker the LCD printer for space that can make plastic and ceramic parts.

CosmicMaker operates independent of gravity and pressure. It is the lightest, most compact, most reliable, lowest energy and most productive 3D printer ever designed for space.

Working in partnership with

3D Printing in Space

CosmicMaker

The unique advantages that LCD 3D printers provide have made it the dominant technology in resin printing, but their advantages are even greater in hostile environments, such as ships, war and in space.

With ESA support, Photocentric has invented and patented CosmicMaker the LCD printer for space that can make plastic and ceramic parts.

CosmicMaker operates independent of gravity and pressure. It is the lightest, most compact, most reliable, lowest energy and most productive 3D printer ever designed for space.

Working in partnership with

How we manufacture on earth

These processes have all been finely optimised over decades to make a lot of items, with lots of waste, to achieve the lowest cost possible.

The slice for Additive Manufacturing, seems most suitable to manufacture in space.

If the annual volume of manufactured plastic in the world was a heaped teaspoon of sand then Additive Manufacturing would be just one single grain.

If you look at it by price it would be 25 grains which tells you why AM doesn’t scale.

3D printing mechanisms

These are the ways that AM works; laser melting powder, thermal binder sticking powder, hot plastic extruding or liquid hardening with light.

Powder is problematic in space, liquid resin delivers finer resolution and wider range of properties than thermoplastics, making resin the obvious choice.

Methods of 3D resin printing

These are the methods of printing with resin; polymerising with lasers, DLPs or LCDs.

The only one that meets all the criteria for space is LCD, the dominant technology on earth with millions made every year is the right one for space.

We don’t want astronauts to have to become 3D printing technicians. There is a better way…

We tested CosmicMaker in every orientation, including complete 360 degrees contra-rotational movement while printing, it works reliably. Making everything from plastics to ceramics.

- An autonomous machine, with gantry moving between CosmicMaker nodes, all carrying out different processes, making different products; one for contact lenses and one for Silicon Carbide heat shields.

- The fastest, most reliable LCD printing process integrated into an autonomous machine. The gantry moves at 5m/sec, carrying out one operation every second.

- Near to 100% overall equipment efficiency.

- It produces 2 tonnes of plastic a day, but its not the output that’s important, it’s the reliability.

We don’t want astronauts to have to become 3D printing technicians. There is a better way…

We tested CosmicMaker in every orientation, including complete 360 degrees contra-rotational movement while printing, it works reliably. Making everything from plastics to ceramics.

- An autonomous machine, with gantry moving between CosmicMaker nodes, all carrying out different processes, making different products; one for contact lenses and one for Silicon Carbide heat shields.

- The fastest, most reliable LCD printing process integrated into an autonomous machine. The gantry moves at 5m/sec, carrying out one operation every second.

- Near to 100% overall equipment efficiency.

- It produces 2 tonnes of plastic a day, but its not the output that’s important, it’s the reliability.

CosmicMaker can make

Thermosets

All properties possible – elastomeric, high temperature, ESD, high impact etc

Composites

Fibre reinforced polymer, ceramic filled etc

Ceramics

Silicon carbide, Alumina etc

Metals

Stainless steel, Titanium etc

Thermosets

All properties possible – elastomeric, high temperature, ESD, high impact etc

Composites

Fibre reinforced polymer, ceramic filled etc

Ceramics

Silicon carbide, Alumina etc

Metals

Stainless steel, Titanium etc

In the news

ESA-funded Accelerator selects two 3D printing companies to advance in-orbit manufacturing

3D Printing Industry, September 7th 2023

>

Photocentric announces partnership to make a 3D printer to print SiC in space with ESA

Space East, July 10th 2024

>

Welcoming Innovators into the In-Orbit Manufacturing Accelerator

Catapult, 2024

>