Liquid Crystal Magna Resource Hub

Getting Started

Follow this flow for all the information you require to begin using your LC Magna.

Alternatively use the below navigation to navigate to sections of this start up guide.

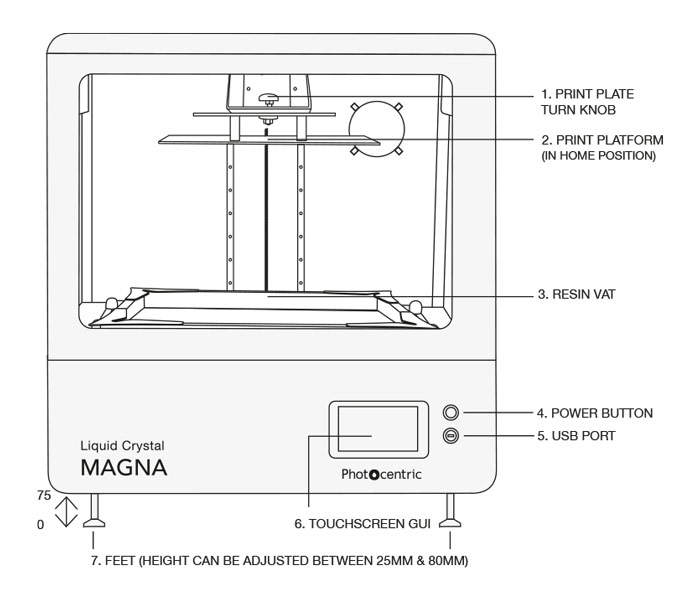

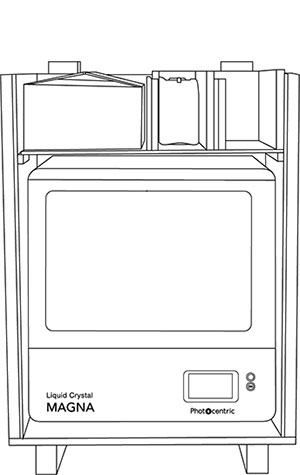

Liquid Crystal Magna at a glance

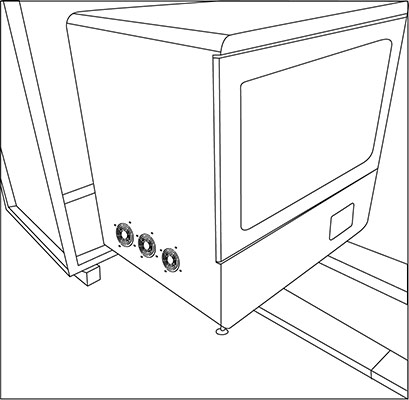

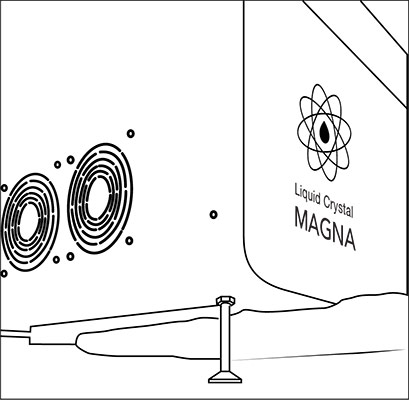

Figure 1: Liquid Crystal Magna front view

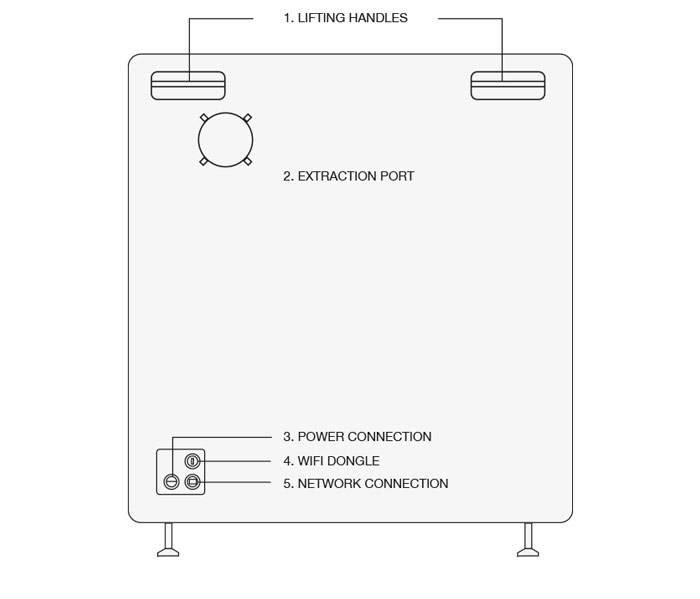

Figure 2: Liquid Crystal Magna back view

Suitable Location

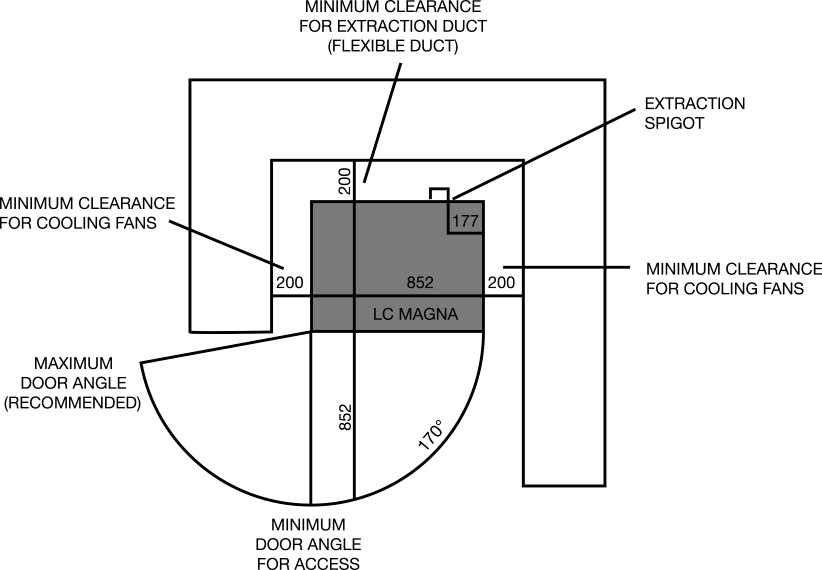

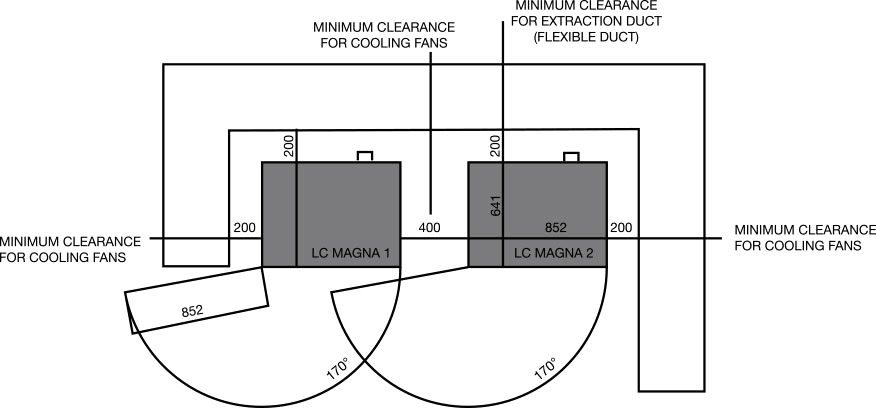

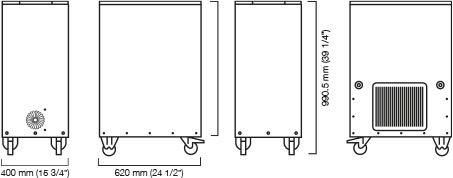

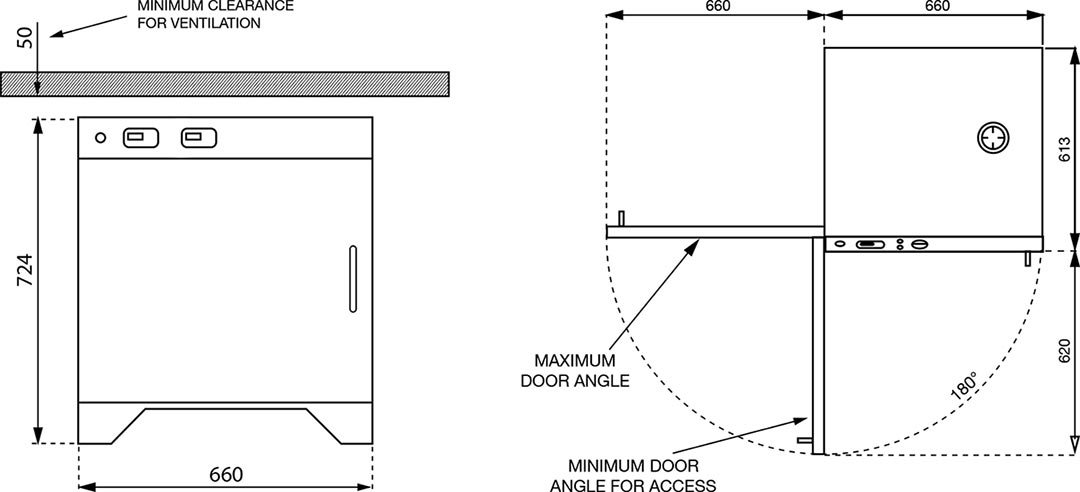

When choosing a suitable location for your Liquid Crystal Magna, allow plenty of space (see Figure 3 and Figure 4).

All diagrams have dimensions in millimetres unless otherwise stated. Consider the ergonomics of operating the machine.

Ambient light

Liquid Crystal Magna uses resins that cure when exposed to light in the blue part of the spectrum. The resins are highly sensitive and will cure in ambient white light. Operate your printer in a low-light environment. Always avoid direct sunlight. Red lighting can be used as it does not interact with the resin. If necessary, make it possible to reduce the lighting level when handling resin.

Choose a location with operating temperature between 20-25°C.

Note:

Permanently placing the printer on a heavy-duty, wheeled trolley will allow easy repositioning in future and easy access for maintenance. Make sure the trolley is rated to safely carry the load (110 kg minimum). Make sure the trolley wheels have brakes to keep the machine still during operation and maintenance.

Liquid Crystal Magna weighs 110kg. Carefully consider how your printer will be lifted into position (refer to figure 2). Allow plenty of space to work and remove any potential obstructions. Allow plenty of time to complete the job safely.

Figure 3: Clearance’s required for LC Magna printer – as viewed from above

Figure 4: Clearances required for multiple LC Magna printers – as viewed from above.

Un-Crating LC Magna

1. Remove top and front panels

2. Remove the resin bottles and accessory box.

3. Remove the shelf and side panels.

NOTE: If possible, do not dispose of the crate.

Lifting LC Magna

We recommend using a forklift truck or pallet lifting machine to handle your Liquid Crystal Magna.

– Lift the printer from the front or back, not the side (Figure 5).

– Adjust the fork spacing so that both forks fit between the feet.

– Make sure that the forks reach fully under the printer before lifting. This way the weight is distributed across structural parts of the printer chassis (Figure 6).

NOTE: Lifting Magna incorrectly could cause serious damage to critical, functional parts of the machine.

– If the printer is being carried any distance by forklift truck, secure it to the forks using ratchet straps to prevent it moving or bouncing on the forks.

– Pieces of rubber mat can be used to protect the printer from being damaged by the forks.

Figure 5: Lifting Magna with a forklift

Figure 6: Making sure forks reach fully under the printer before lifting.

Alternatively, you can lift Liquid Crystal Magna with a winch or hoist (eg an engine hoist).

– Make sure the equipment used is rated to safely carry the load.

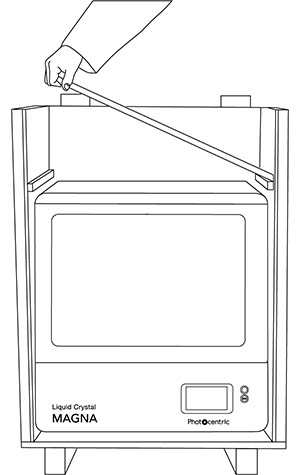

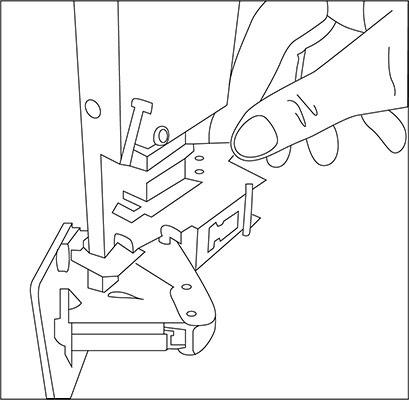

– Remove the door of the printer by unclipping the hinges (Figure 7). Be careful to support the weight of the door at all times. This is a two-person task.

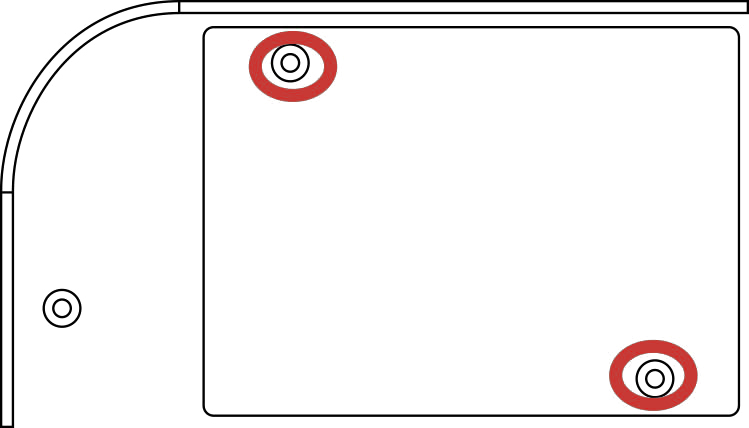

– Remove the two rectangular panels on the back of the machine (Figure 8).

– Two lifting straps can be threaded through the machine from front to back. Secure both ends of each strap to the lifting hook.

– Make sure the straps are rated to safely carry the load.

– Be aware that the straps may move as the machine is lifted.

– Pieces of foam or cardboard can be used to protect the printer from being damaged by the straps.

– If the printer is being carried on a mobile hoist, keep it steady and under control at all times.

Figure 7: Removing the door of Magna

If it is necessary to lift Liquid Crystal Magna manually, four people will be required.

– Remove the door and cover panels as described above. This provides four secure handholds at the top corners of the printer.

– It is also possible to lift the machine at the base.

– It may be safest to lift the machine in two stages. Use a low table or a stack of pallets to provide a stable surface at an intermediate height.

– Use safety gloves with a secure grip surface to prevent slipping.

– Ensure everybody involved is comfortable with the weight.

– Follow proper safe lifting practice.

– When lifting the printer at the base, keep it level and stable at all times.

Figure 8: Remove the two fixings to the small panels in the back top corners of the printer to reveal the lifting handles.

Extraction

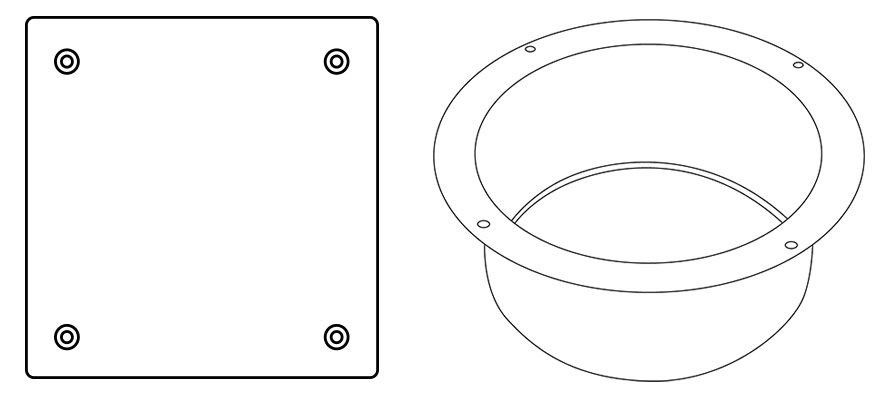

Liquid Crystal Magna has an extraction port on the back, with a cover plate. The cover plate is attached by four screws (Figure 9). A 100mm spigot is supplied in the accessory box. This can be attached to the back of the machine if the cover plate is removed. Re-use the four screws to secure the spigot. This will allow you to connect 4-inch ducting to the printer.

Extraction is recommended if Magna is operated in a confined or poorly ventilated space.

It should not be necessary in most cases. The fumes from the printing process are not harmful, but the smell can be unpleasant.

The volume of air inside the printer is approximately 320 litres (0.32 m3). A maximum of 2 air changes per minute should be used. This corresponds to a flow rate of 640 litres per minute or 38 m3 per hour. Using a higher flow rate will cause excessive cooling of the resin which may affect print performance. It will also increase the noise level and may draw dust into the printer.

In cases where a higher extraction flow rate must be used, most of the fumes can be removed from Magna in just a few minutes. After each print is finished, turn on the extraction for a short period before opening the printer door.

Photocentric recommends BOFA extraction systems to connect to the Liquid Crystal Magna printer and the Air Wash L station. For more information click here.

Power Requirements & Connectivity

– Liquid Crystal Magna requires an earthed mains power supply with a voltage of 100 VAC – 240 VAC and a frequency of 50 Hz – 60 Hz.

– It has a power consumption of 1300 W. It will draw a current of 7.0 A when connected to a 240 VAC supply, or 13.5 A when connected to a 100 VAC supply.

– Only connect Liquid Crystal Magna to the mains socket using the power cable supplied.

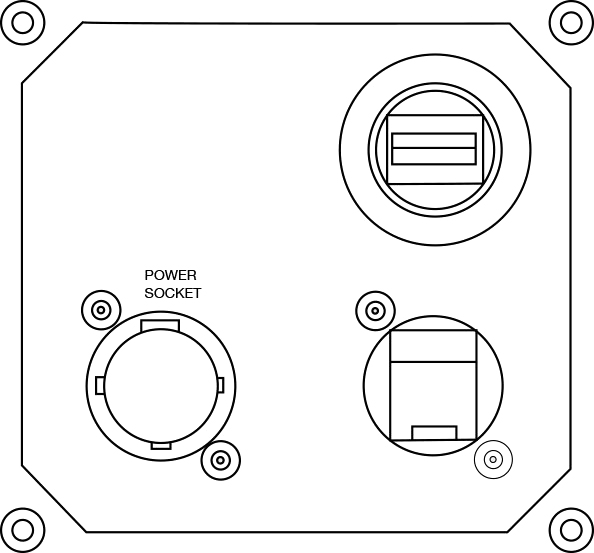

– The printer power socket is on the back of the machine, at the right side (Figure 10).

– Always plug the power cable into the mains socket and the printer before switching on the power at the mains socket.

– Similarly, always switch off the power at the mains socket before unplugging the power cable from either the printer or the mains socket.

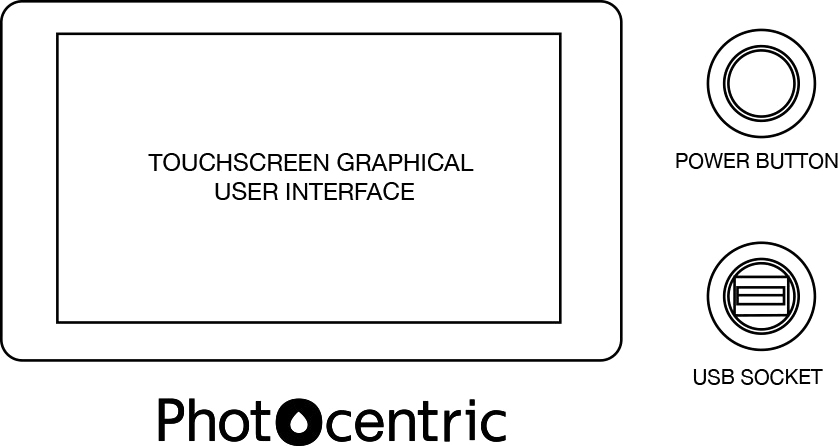

– The power button is on the front of the machine, at the right side (Figure 11).

– In case of emergency you can switch off the printer by pushing the power button.

– Liquid Crystal Magna has a USB socket and an RJ45 network socket on the back (Figure 10).

– Plug a Wi-Fi dongle (provided) into the USB port if you would like to access your printer via a Wi-Fi network connection.

– Plug a network cable (eg CAT6) into the RJ45 socket if you would like to access your printer via a wired network connection.

– The USB socket on the front of the printer allows you to upload print files via a USB flash drive (Figure 11).

Figure 10: Magna back view detail on port cover plate

Figure 11: Magna front view

Installing Photocentric Studio

Minimum System Requirements

– Windows 7, 8 or 10

– Minimum 2.0 Ghz processor speed 2 Cores. Recomended 4 cores.

– GPU capable of running opengl version 3.0 or higher. We recommend that you use GPU with at least NVIDIA GTX1050 specifications.

– .net framework version4.0

– 64bit system: minimum 2Gb of Ram, recommended 4Gb.

– 32bit system: minimum 1Gb or Ram, recommended 2Gb

You can run the software using MacOS by using a virtual workstation with Windows installed on it.

1. Extract the Photocentric Studio zip folder and run the .msi application

Note: If Windows Defender prevents the installation from starting simply click ‘More Info’ then ‘Run Anyway’ to begin the installation process.

2.The set up wizard will then load on your screen. To proceed with the installation simply click Next.

3. Now select the location for your installation to be saved to. If you wish to change the location simply click Browse and select a new location of your choice. Once the location has been selected click Next.

4. Once you have selected the location of the installation click Next to begin the installation of the software.

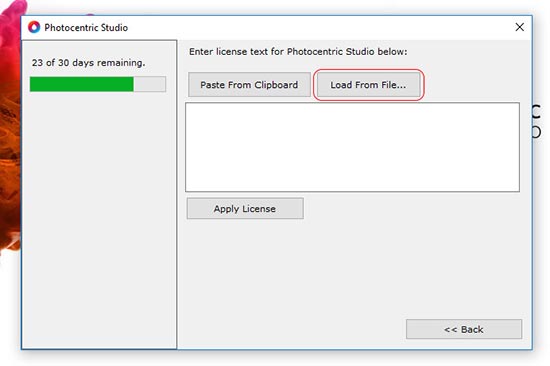

5. Installation has now completed, click Close and you can now open the software. When opening the software you will see a section to enter your license number which can be found on the USB in the envelope of the ancillary box, click on this section and enter your license number provided into the field as shown.

Note: The software comes with a 30 day trial. If you wish to use the trial before activating your license simply click ‘Continue Evaluation’.

Graphics Card Setup

You can run the software using MacOS by using a virtual workstation with Windows installed on it.

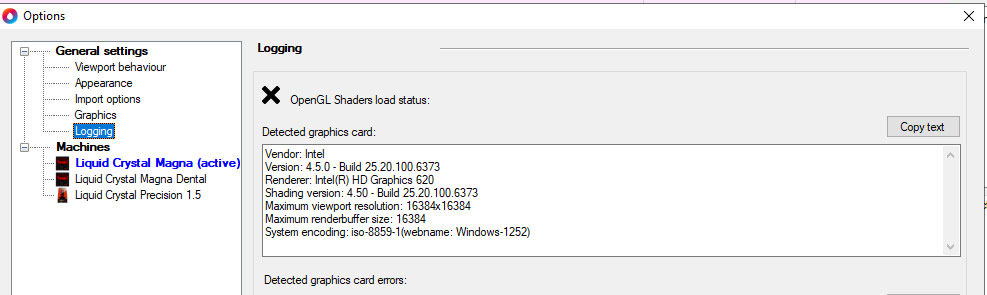

– Your system could operate with an intergrated or a non-intergrated graphics card. Photocentric Studio by default may run with the intergrated graphics card. To check this click ‘File’, ‘Configuration’, ‘General Settings’, ‘Logging’ (figure 1).

– If yes follow these steps to enable Photocentric Studio to run with the non-intergrated graphics card.

Figure 1: Graphic card settings

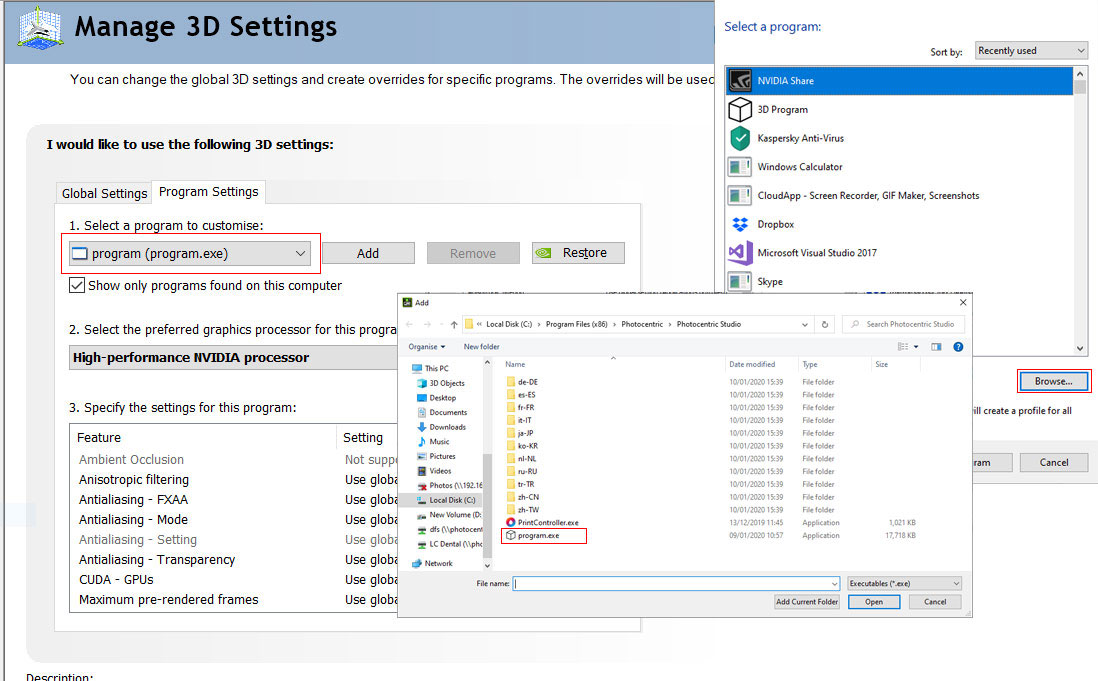

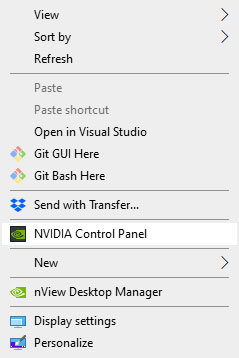

1. Right click on your desktop and select NVIDIA control panel (figure 2)

2. Select ‘Program Settings’, click ‘Add’ (figure 3).

3. Select ‘Local Disk (C), ‘Program Files’, ‘Photocentric’, ‘Photocentric Studio’ then click ‘Open’ (figure 3).

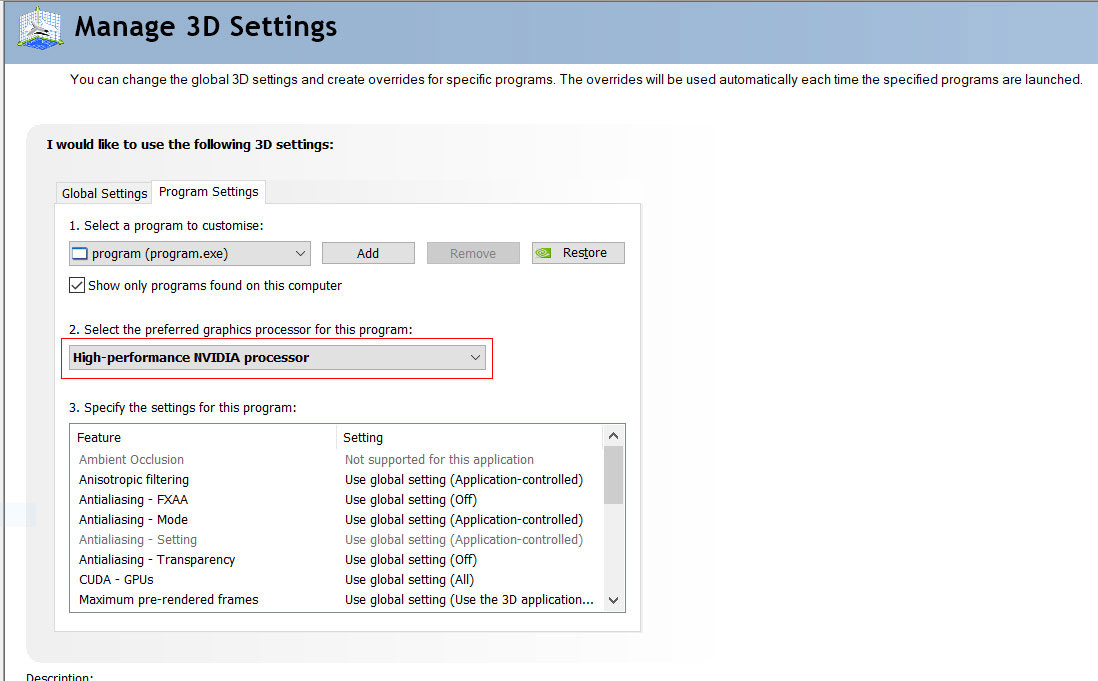

4. Make sure ‘Preferred Graphics Processor’ is ‘Nvidia Processor’ (figure 4)

Figure 2: Nvidia Control Panel

Figure 3: Photocentric Studio (click to enlarge)

Figure 4: Preferred Graphics Processor (click to enlarge)

Photocentric Air Wash L At a Glance

Figure 1: Air Wash L overivew

The tank is built in stainless steel and holds 90 l (24 US gallon) chemicals and works with an internal air flow of 40 l/min at a pressure of 160 mbar (2.3 psi). The Air Wash L has a drainage pipe of 1 1/4 BSP.

Suitable Location

When choosing a suitable location for your Photocentric Air Wash L, choose a flat stable location with enough space for the unit (see dimensions in Figure 2) and leave extra room over the unit to allow opening the lid. Consider the ergonomics of operating the wash unit.

The installation location should have an operating temperature in the range 18-28 °C. Moreover, a low-light or red lighted work environment is recommended, as Daylight resins will cure in ambient white light. Always avoid direct sunlight. This is especially recommended when handling unwashed platforms and parts.

Always use Photocentric Air Wash L in a well-ventilated area and consider vicinity to extraction duct.

To connect the Air Wash L to extraction, use a screwdriver to open the vent on the top of the unit and fasten a 4-inch spigot, which can be linked to the extraction duct. The spigot should be purchased separately, (as a reference, please see here.)

Figure 2: Air Wash L dimensions

Figure 3: Air Wash L Recommended Extraction

Photocentric recommends BOFA extraction systems to connect to the Liquid Crystal Magna printer and the Air Wash L station. For more information click here.

Unboxing & Placing Air Wash L

Photocentric Air Wash L is packed in a cardboard enclosure. Please do not lift the unit, as it weighs 56 kg (124 lbs). To unbox Air Wash L, remove the plastic packaging and remove the cardboard sleeve covering the unit. Check that the caster brakes are inactive, carefully slide the unit out of the cardboard base, on its casters, and place it on the desired location. Two people are recommended for this operation. Use safety gloves with a secure grip surface to prevent slipping.

Once satisifed with the location, press caster brakes to ensure stability of the unit while operating.

Power Requirements

• Photocentric Air Wash L requires an earthed mains power supply with a voltage of 110VAC or 220VAC (depending on the unit).

• Photocentric Air Wash L power consumption is rated at 35-45 watts.

• Only connect Photocentric Air Wash L to the mains socket using the power cable supplied.

• The wash unit power cable is on the right-hand side of the machine.

• Always plug the power cable into the mains socket and into the wash unit before switching on the power at the mains socket.

• Similarly, always switch off the power at the mains socket before unplugging the power cable from either the wash unit or the mains socket.

• The wash unit power cable is on the right-hand side of the machine

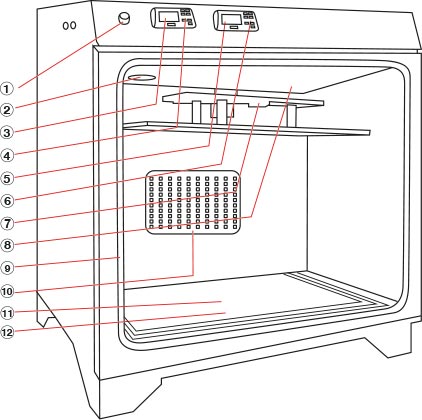

Introduction to Cure L2

Recognising the essential parts of the Cure M+ will increase the efficiency of use and aid if the need to troubleshoot ever appears

Figure 1: Cure L2 General layout

1. On Off switch

2. Internal Fan

3. Temperature unit

4. Temperature adjustment

5. Timer controller

6. Timer adjustment

7. Hanging bracket

8. Heater unit

9. Door seal

10. Rear light

11. Bottom light

12. Glass shelf

Suitable Location

When choosing a suitable location for your Photocentric Cure L2, allow plenty of space (see Figure 2 and Figure 3). All diagrams have dimensions in millimetres unless otherwise stated. Consider the ergonomics of operating the cure unit.

Figure 2: Cure M +Space requirements Front View

Figure 3: Cure M+ space requirements, plan view.

Unboxing & Placing Cure L2

Remove the outer packaging and recycle it.

Photocentric Cure L2 weighs 64 kg. Carefully consider how it will be lifted into position. Allow plenty of space to work and remove any potential obstructions. Four people will be required to lift Photocentric Cure L2, one at each corner. Use safety gloves with a secure grip surface to prevent slipping. Ensure everybody involved is comfortable lifting the weight. Follow safe lifting practice.

Keep the cure unit level and stable at all times. Always use Photocentric Cure L2 in a well ventilated area.

Power requirements

• Photocentric Cure L2 requires an earthed mains power supply with a voltage of 100VAC – 240VAC and a frequency of 50 Hz – 60 Hz. It has a power consumption of 1000 W.

• This machine has been developed to work on either a power supply of 110VAC or 240VAC

• Only connect Photocentric Cure L2 to the mains socket using the power cable supplied.

• Always plug the power cable into the mains socket and the cure unit before switching on the power at the mains socket.

• Similarly, always switch off the power at the mains socket before unplugging the power cable from either the cure unit or the mains socket.

• The cure unit power socket is on the back of the machine on the right side. The power switch is on the front of the machine, at the top left (Figure1-1).

Further Support