3D printing solutions

Industrial parts

To be successful at making parts, as opposed to prototypes, you need fast, cost-effective, reliable printing processes with functional resins.

Photocentric’ s LCD technology enables lots of parts to be printed very quickly. Our software and design for Additive skills enable the parts to be designed for mass-manufacture.

Our resins deliver functional parts that will last for decades in industrial applications.

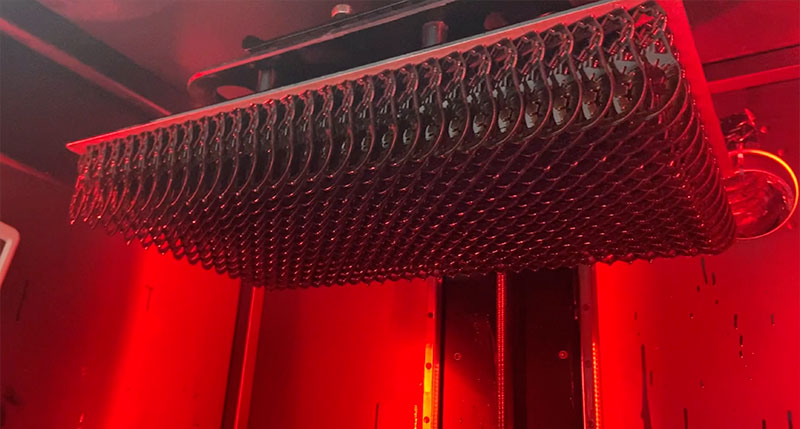

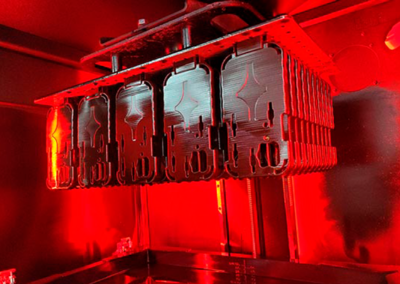

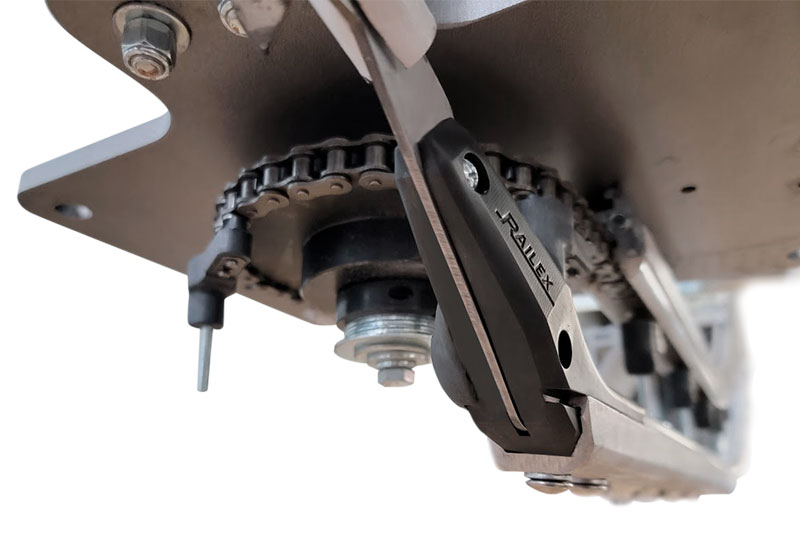

VXL Technologies helps Railex increase functionality and efficiency of garment conveyor system

By integrating 3D printing into both prototyping and production stages, VXL Technologies was able to reduce development time, increase product reliability, and save on costs for Railex by using transfer connections made on LC Magna.

“We were able to reduce development and production time significantly, to meet deadlines”

Matthew Mendez

Owner, VXL Technology

VXL Technologies helps Railex increase functionality and efficiency of garment conveyor system

By integrating 3D printing into both prototyping and production stages, VXL Technologies was able to reduce development time, increase product reliability, and save on costs for Railex by using transfer connections made on LC Magna.

“We were able to reduce development and production time significantly, to meet deadlines”

Matthew Mendez

Owner, VXL Technology

Cost effective and fast solution to component failure problem

Using LC Magna and Magna Hard Black resin, Wurtec were able to design, print, fit, release and produce nearly 800 components in 2 weeks, instead of months, with annual cost savings of over $43k! (The printing took 5 hours with 1 LC Magna).

*12,600 pcs per year

Crack Eraser solves windshield repair woes with Photocentric LC Magna

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser – which helps other entrepreneurs start their own auto glass repair businesses – to develop a part for its repair kit system.

The proprietary technology has helped Crack Eraser to solve the most challenging aspect of windshield repair, that of drilling into the top layer of laminated windshield glass at the point of impact where damage occurred.

“The 3D Printing Store was invaluable in supporting us in development of this industry leading product through months of testing and refinement. We can’t thank the 3DPS enough for their outstanding support in the development of our industry leading 3D printed Drill Stop Collet™!”

Tim Evans

Owner, Crack Eraser

Phone Skope focuses on LC Magna solution to solve manufacturing challenge

Digiscoping leader, Phone Skope, has adopted a Photocentric additive manufacturing solution to manufacture its custom-moulded digiscoping adaptors. The US-based manufacturer makes precision engineered adaptors for almost any smartphone, enabling a smartphone camera to capture enhanced images and video through a scope for birding, wildlife, microbiology and astrology applications.

““The speed and agility of additive manufacturing has given us the ability to expand coverage for more phones giving us a larger market to pursue”

Jason Bairett,

Operations Manager, Phone Skope

1,000,000 3D Printed Part Order For Adhesives Technology

Merit3D, a leading additive manufacturing company, is producing 1,000,000 hangers for Adhesives Technology using 3D printing technology. The hangers are required for every project Adhesives’ undertakes, but the production process was halted due to the unavailability of the injection mold tool.

Merit3D’s solution helped Adhesives Technology eliminate the extra cost and wait time for delivery of a new tool and bring manufacturing back to the USA.

Adapt and Innovate with 3D Printing

As a manufacturer of equipment for laundry services, Girbau sought to improve the efficiency of their folding machines. In realising that the air flow of their folding machine was not optimal for the precision folding they needed, Girbau turned to 3D printing for the speed, efficiency, limitless design possibilities, and cost-effectiveness of this technology to create the single solution part they needed to optimise their folding machines.

“Sculpteo’s experts supported us throughout the printing process so we could go on and print the model with the best solution to match our challenges.”

Sylvian Ferris

R&D Designer, Girbau

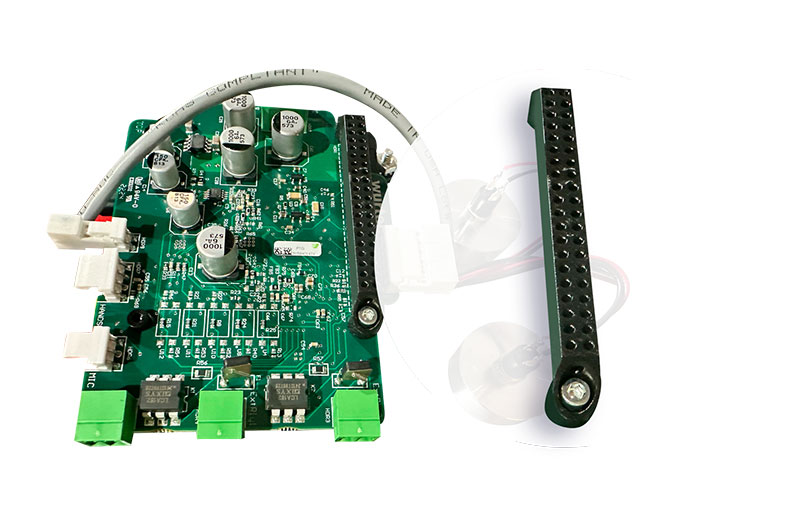

Solution to component failure problem

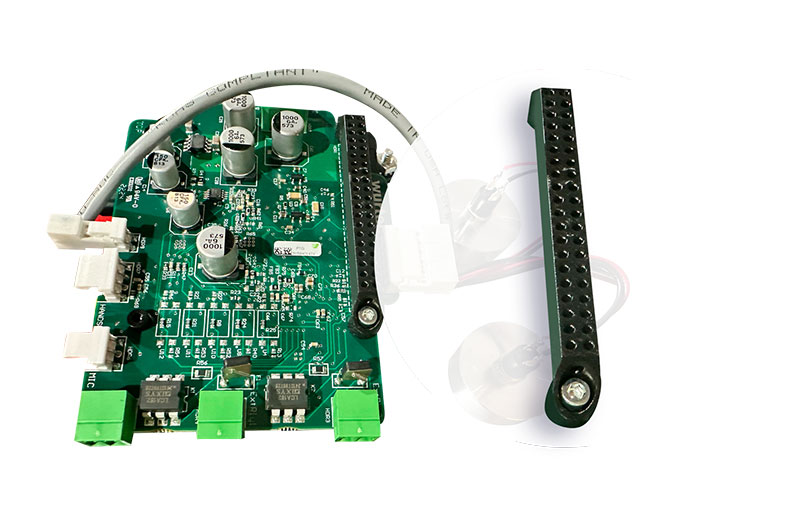

Leveraging the advanced capabilities of the LC Magna, we designed, printed, fitted, released, and produced 791 components in approximately two weeks. Traditionally, this process would have taken months, and we would not have considered designing this component due to the time and cost constraints associated with plastic injection molding.

Challenge

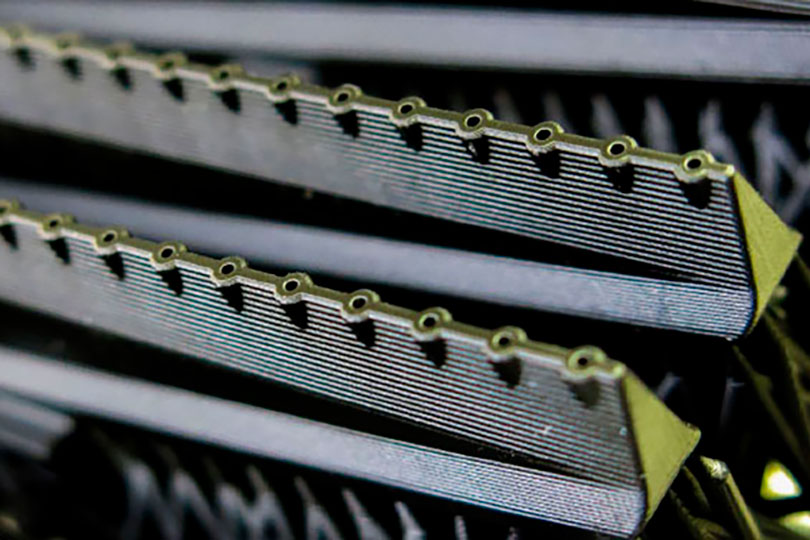

The project faced several challenges, including field failures in the Wur-Com system where the 40-pin header was getting damaged during installation, leading to short circuits. The main challenge was component sourcing, with time to market being a secondary concern.

Solution

To solve this problem, we researched existing solutions but found none available on the market. Leveraging the advanced capabilities of the LC Magna, we designed, printed, fitted, released, and produced 791 components in approximately two weeks. Traditionally, this process would have taken months, and we would not have considered designing this component due to the time and cost constraints associated with plastic injection molding.

Expedited Change Process

Not only can we quickly modify our current products by adding additive components, but we can also swiftly adapt these components to meet unforeseen needs or switch materials for better application performance. The time savings in this change process far surpasses that of altering machined, cast, or molded components.

Advantages

Incomparable time to market

The time to market is incomparable between additive manufacturing and traditional methods like injection molding or machining. We can go from inception to impact in approximately two weeks, compared to around 20 weeks or more for an injection-molded component.

Very low cost

With our additive components, there are no tooling costs, and we have multiple outsourcing options if needed. In contrast, a similar molded component would require either relocating the tool or creating a new one with a new supplier, further impacting production.

Environmental Impact

We now have the option to reduce our impact on the environment with plant based materials, especially for components that are not customer interfacing that require a specific color.

Phone Skope focuses on Photocentric LC Magna solution to solve manufacturing challenge

Digiscoping leader, Phone Skope, has adopted a Photocentric additive manufacturing solution to manufacture its custom-moulded digiscoping adaptors. The US-based manufacturer makes precision engineered adaptors for almost any smartphone, enabling a smartphone camera to capture enhanced images and video through a scope for birding, wildlife, microbiology and astrology applications. The Photocentric additive manufacturing solution – carried out via manufacturing service provider partner Merit3D – includes Photocentric LC Magna printers and post-processing units, allowing adaptors to be modelled and created at speed without the need for costly and time-consuming moulding.

A fast moving market – The Challenge

“Phone Skope’s manufacturing was challenged by the fast-moving nature of the market, requiring its products to be compatible with a huge number of new phone models released every year,” says Sally Tipping, Photocentric. “In order to create a compatible digiscoping adaptor for a particular phone model, a mould would have to be created for each new case, and there was always a chance that the phone itself may not be a commercial success. This meant that Phone Skope had to choose between which models to support and create moulds for in order to maintain viability. 3D printing was an excellent solution to this problem, giving Phone Skope the flexibility to bring a greater variety of adaptors to market at speed without the cost implications of creating additional moulds. Phone Skope products are renowned around the world for their precision and durability, and so it was also vital that these characteristics were retained without compromise.”

Photocentric and LC Magna – The perfect solution

To produce the cases, Merit3D used its 8 Photocentric LC Magna printers and Photocentric post-processing units, the Air Wash L and Cure L2 units. Merit3D also chose Photocentric’s Daylight Magna Duramax resin. Phone Skope’s design is a simple two-part system that is interchangeable and works with most smartphone and optics combinations. With just a couple of small design changes to the 3D model, a new case could be designed and printed at a large scale with minimal revisions required using additive manufacturing. This reduced upfront costs and increased the production time considerably, with consistent high-quality output.

The LC Magna suits a wide range of manufacturing applications, offering significant print speed, build volume and cost advantages. Merit 3D also knew that the high-quality prints produced by the LC Magna would significantly reduce the time spent on final finishing thereby further reducing cost and increasing speed to market.

Photocentric’s Studio software and 4D-additive was also used to incorporate the supports required for printing into the actual design of the cases. Depending on the size of the finished product, a single Magna platform could accommodate up to 52 cases. Following a simple workflow within its manufacturing facility, the completion time for each of the orders ranged from 1 to 2 days. The new solution allowed thousands of dollars in equipment costs to be saved on creating a moulding, and times to create a new case model design has also been slashed from 1-2 months to just two weeks. Thanks to the AM solution, a previous minimum order of 2000 units (in order to be viable) was also completely removed.