LC Titan

The Largest LCD 3D Printer in the World

Makes the largest, high resolution, functional parts

LC Titan makes ultra-high-resolution large-format 3D printed parts Parts that can used in real applications, from elastomers to flame retardants.

Unlike Any Other Printer

Large Usable Detailed Parts

Extremely Large

Build volume of 695 x 385 x 1200 mm

(27 3/8 x 15 1/8 x 47 ¼”)

High Resolution

32-inch 8K (7680 x 4320 pixels) LCD screen

Pixel pitch of 91 microns

Full Ecosystem

Print, wash, cure with training, materials, servicing and support

Technical

Specification

Extremely Large Build Volume

695 x 385 x 1200mm

27 3/8 x 15 1/8 x 47 1/4″

High Resolution

91μm pixel pitch

Up to 28mm/hr Print Speed

At 250μm layers

ResinGlide Platform Coating

Easy clean, less waste

Patented Blow-Peel Technology

Reliable, fast printing

Remote Control and Monitoring

4k time-lapse camera

Automatic Resin Control

Auto vat fill and empty

The complete LC Titan processing system

Purpose-built post-processing.

Wide range of functional resins. Full technical support, warranty and service plans.

Wash XL

Three in one. Wash, Rinse and Dry

Purpose-built, effectively cleans large complex parts printed on LC Titan, combining wash, rinse and dry functions in single unit.

Cure XL

Cure Large Parts with Heat and Dual Wavelength Light

Provides uniform heat and dual wavelength light, evenly distributed with 360° platform rotation, delivering dimensionally accurate, tack-free parts.

Wash XL

Three in one. Wash, Rinse and Dry

Purpose-built, effectively cleans large complex parts printed on Liquid Crystal Titan, combining wash, rinse and dry functions in single unit.

Cure XL

Cure Large Parts with Heat and Dual Wavelength Light

Provides uniform heat and dual wavelength light, evenly distributed with 360° platform rotation, delivering dimensionally accurate, tack-free parts.

Wide Range of Functional Resins

From elastomeric to certified flame retardant resins for a range of industries creating functional high-definition parts.

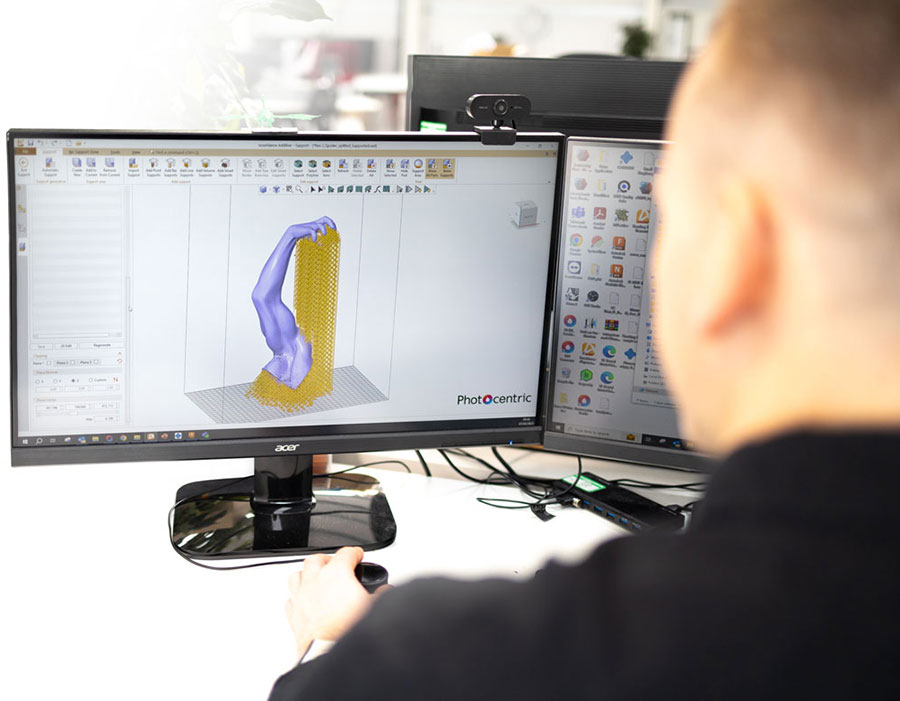

Software

Photocentric Studio and Voxel Dance deliver full large file part preparation and printer user interface, from design to production.

Support

On-site installation and training, service plans, warranties, and full Design for Additive Manufacturing technical support available from personal and online service.

Our team of 3D printing and material science experts are always available to you.

Print Smarter:

Reduce Costs and Accelerate Production

Gorilla

Print Time: 40h 20mins

Resin: Hard Black

Height: 41.4cm

Weight: 2.25kg

Supports weight: 0.3kg

Resolution: 100µm

Engine Cover

Print Time: 32h

Resin: Hard Black

Height: 60cm

Width: 60cm

Depth: 10cm

Weight: 2.6kg

Resolution: 100µm

Neptune

Print Time: 130 hrs (3 prints)

Resin: Hard Black

Height: 215cm

Width: 105cm

Depth: 70cm

Weight: 21.5kg

Resolution: 250µm

Model designed by Sanix3D

Lampshade

Print Time: 29h

Resin: Hard Black

Height: 60cm

Width: 40cm

Depth: 40cm

Weight: 2.3kg

Resolution: 250µm

Running Man

Print Time: 60h

Resin: Hard Black

Height: 177cm

Width: 220cm

Weight: 2.9kg

Resolution: 250µm

Warrior

Print Time: 116h 40mins

Resin: Hard Black

Height: 100cm

Weight: 12kg

Supports weight: 6.5kg

Resolution: 100µm

Genie

Print Time: 65h

Resin: Hard Black

Height: 160cm

Width: 90cm

Depth: 90cm

Weight: 22kg

Resolution: 250µm

Lectern

Print Time: 52h 50m

Resin: Hard Black

Height: 115.9cm

Width: 70cm

Depth: 40cm

Weight: 22kg

Resolution: 250µm

King

Print Time: 102h

Resin: DL110HB

Height: 102cm

Weight: 7.29kg

Supports weight: 1.56kg

Resolution: 100µm

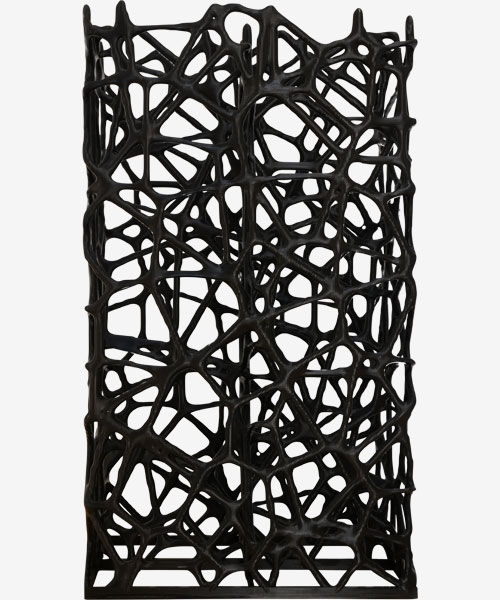

Lattice

Print Time: 60h

Resin: Hard Black

Height: 155cm

Width: 50cm

Depth: 40cm

Weight: 2.6kg

Resolution: 250µm

Total Cost of Ownership (TCO):

See the Full Picture

The costs of a 3D printer go beyond the purchase price

We believe in complete cost transparency, so we include waste, labour, consumables, materials, maintenance, energy use, in fact everything in our TCO.

“We definitely love our Photocentric printers, and the Titan is a game changer”

Brad Wriedt, Blue Hippo

Printer Comparison

Book a Consultation

Want to explore large format, high resolution printing with Titan, schedule a call with our experts.

We’ll use these details to keep you up to date with Photocentric news and insights. You can unsubscribe at any time. View our Privacy Policy for more details.

82%

UK Precision Engineering at Our Core

Liquid Crystal Titan is designed and assembled in the UK with 82% UK sourced components.