Strategic partners bringing expertise

in design for additive manufacturing

Working in a strategic partnership with BASF ForwardAM, their specialised 3D printing division, to design, manufacture, and

supply a wide range of high-performance resins to enable the mass manufacture of functional plastic parts.

Our solution

Functionality

Combining the technical expertise of both companies to develop functional materials for high volume production of plastic parts.

Cost efficiency

We recognise that AM can reach its full potential only when materials are closer in cost to IM.

Experience

Decades of research and production of Polyurethanes

Know how

Building on many years’ experience of polyurethane and photopolymer formulations.

Quality

Regulatory, batch to batch control. Own oligomers & customized solutions

BASF is a well-known, well respected, global company. Photocentric is an innovative, agile company. Together, through our strategic partnership we can offer companies a real option to make end use parts, using photopolymer resin, on a large scale, at an acceptable cost. The value that the alliance brings us is a real power of collaboration, our shared vision, values and combined intellectual rigor enables us to drive real change in the additive industry.

Paul Holt

Managing Director, Photocentric

We are strongly connected through a long-standing strategic partnership with Photocentric underpinned by our shared goals. We are combining the talents and deep chemical and engineering understanding of our teams which work closely together on developing novel 3D printing materials best fitted to exploit the advantages of unique Photocentric machines. Together, we aim to meet the very high performance requirements of our customers with chemistry, materials and hardware that are even better suited for end-use applications.

Dr. Erika Fantino

Head of Business Line Photopolymers BASF ForwardAM

Ultracur3D® Photopolymers

Joining our combined expertise in polymer manufacturing

Photocentric and BASF ForwardAM have created resins with improved performance and solutions better suited for end-use applications. Ultracur3D® daylight reactive urethane photopolymers, developed especially for the Liquid Cyrystal Magna and Liquid Crystal Titan, deliver high performance and consistency to meet your project demands.

Ultracur3D® EPD1006

It is is an easy-to-use daylight resin ideal for prototyping, jigs and fixtures. The material provides high stiffness and flexibility, good impact resistance and nice surface finish.

Material Properties:

- Impact strength (Notched Izod): 35 J/m

- Young’s modulus: 1500 MPa

- Tensile strength: 40 MPa

- Elongation at break: 25 %

Ultracur3D® EPD1086

A cost-effective solution with well-balanced mechanical properties for a wide range of applications.

Material Properties:

- Young’s modulus: 1810 MPa

- Tensile strength: 42 MPa

- Elongation at break: 26 %

- Hardness shore: 81 D

Ultracur3D® EPD2006

A very high stiffness daylight reactive urethane photopolymer with good

temperature stability ideal for large-scale objects.

Material Properties:

- Heat deflection temperature: 81°C

- Young’s modulus: 2370 MPa

- Tensile strength: 50 MPa

- Elongation at break: 10.3 %

Ultracur3D® EPD3500

An ideal solution for engineering prototypes, also when translucency is required. The material provides an optimum combination of high strength, high stiffness and good impact resistance.

Material Properties:

- Impact strength (Notched Izod): 25 J/m

- Young’s modulus: 2500 MPa

- Tensile strength: 60 MPa

- Elongation at break: 18 %

Ultracur3D® EPD4006

An extremely tough and durable material ideal for functional applications. It is an easy-to-use material which provides a smooth surface finishing.

Material Properties:

- Impact strength (Notched Izod): 46 J/m

- Young’s modulus: 1800 MPa

- Tensile strength: 45 MPa

- Elongation at break: 45 %

Ultracur3D® FLD5006

An optimised solution for applications which require a combination of high energy return, high elongation and tear strength.Material Properties:

- Tear strength: 35.4 kN/m

- Tensile modulus: 52.6 MPa

- Tensile strength: 19.1 MPa

- Elongation at break: 144 %

Ultracur3D® Photopolymers

Joining our combined expertise in polymer manufacturing

Photocentric and BASF ForwardAM have created resins with improved performance and solutions better suited for end-use applications. Ultracur3D® daylight reactive urethane photopolymers, developed especially for the Liquid Cyrystal Magna, deliver high performance and consistency to meet your project demands. They combine the right technology with selected partners and ensure a tailor-made solution for your application needs.

Ultracur3D® EPD1006

Perfect for creating functional parts capable of movement and flexibility without breaking.

Optimised for:

- Ideal for functional parts

- Engineering

- Prototyping

- Tensile Modulus (Low – High)

- Impact Strength (Low – High)

Ultracur3D® EPD1086

A multi-purpose daylight resin suitable for a wide variety of applications with balanced mechanical properties.

Optimised for:

- Cost-effective solution

- Engineering

- Prototyping

- Tensile Modulus (Low – High)

- Hardness (Soft – Hard)

Ultracur3D® EPD2006

Rigid, durable and long-lasting material which delivers the finest detail possible.

Optimised for:

- Parts requring resilience with little compression

- Engineering

- Prototyping

- Tensile Modulus (Low – High)

- Impact Strength (Low – High)

Ultracur3D® EPD3500

Strong translucent daylight resin with superior strength and stiffness.

Optimised for:

- Engineering

- Prototypes

- Translucent parts

- Tensile Modulus (Low – High)

- Hardness (Soft – Hard)

Ultracur3D® EPD4006

Ideally suited for making large-scale objects where a hard finish is essential.

Optimised for:

- Functional applications

- Parts requiring high impact resistance

- Smooth surface finish

- Tensile Modulus (Low – High)

- Impact Strength (Low – High)

Ultracur3D® FLD5006

Optimised for applications which require a combination of high energy return, high elongation and tear strength.

Optimised for:

- Footwear e.g midsoles

- Cushioning e.g bike saddle

- Grips and handles

- Elongation (Low – High)

- Rebound Resilience (Low – High)

Chemical Resistance & UV Stability Tests

To fulfill the requirements of different industries and to respond to our customers’ needs, we are constantly testing the mechanical properties of our materials according to the respective norms. In joint cooperation with our partner BASF Forward AM, we have performed specific chemical & weathering tests.

Chemical Resistance & UV Stability Tests

To fulfill the requirements of different industries and to respond to our customers’ needs, we are constantly testing the mechanical properties of our materials according to the respective norms. In joint cooperation with our partner BASF Forward AM, we have performed specific chemical & weathering tests.

Liquid Crystal Opus

Ultracur3D® UV Materials

We are pleased to confirm that ten different Ultracur3D® photopolymers are now fully validated and print-ready with LC Opus:

DM 2505, EL 4000, FL 60, RG 35, RG 50, RG 1100, ST 45, ST 45M, ST 1400, ST 80

Case study

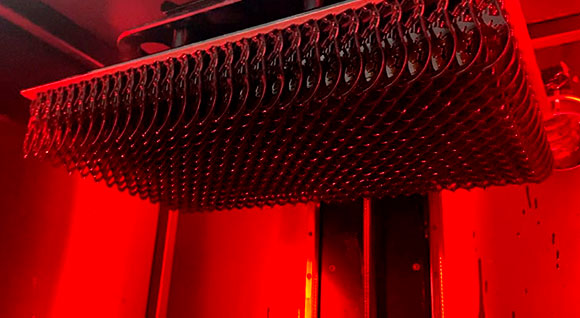

1,000,000 3D printed part order for Adhesives Technology

Merit3D, a leading additive manufacturing company, is producing 1,000,000 hangers for Adhesives Technology using Liquid Crystal Magna and BASF ForwardAM Ultracur3D® EPD1006 Resin . The hangers are required for every project Adhesives’ undertakes, but the production process was halted due to the unavailability of the injection mould tool.

Case study

Adapt and innovate with 3D Printing using

Ultracur3D® EPD 1006

As a manufacturer of equipment for laundry services, Girbau sought to improve the efficiency of their folding machines. In realising that the air flow of their folding machine was not optimal for the precision folding they needed, Girbau turned to 3D printing for the speed, efficiency, limitless design possibilities, and cost-effectiveness of this technology.

Case study

3D Printing for Model Railways with

Ultracur3D® EPD 2006

In Germany, cirp, a 3D Printing Bureau were approached by modellbahn.blog, a specialist online model railway retailer that offers service and a wide range of spares and accessories to model railway enthusiasts. Learn how they used Liquid Crystal Magna and BASF Forward AM Ultracur3D® Daylight resin.

Case study

1,000,000 3D printed part order for Adhesives Technology

Merit3D, a leading additive manufacturing company, is producing 1,000,000 hangers for Adhesives Technology using Liquid Crystal Magna and BASF ForwardAM Ultracur3D® EPD1006 Resin . The hangers are required for every project Adhesives’ undertakes, but the production process was halted due to the unavailability of the injection mould tool.

Case study

Adapt and innovate with 3D Printing using Ultracur3D® EPD 1006

As a manufacturer of equipment for laundry services, Girbau sought to improve the efficiency of their folding machines. In realising that the air flow of their folding machine was not optimal for the precision folding they needed, Girbau turned to 3D printing for the speed, efficiency, limitless design possibilities, and cost-effectiveness of this technology to create the single solution part they needed to optimise their folding machines.

Case study

Adapt and innovate with 3D Printing using Ultracur3D® EPD 1006

In Germany, cirp, a 3D Printing Bureau were approached by modellbahn.blog, a specialist online model railway retailer that offers service and a wide range of spares and accessories to model railway enthusiasts. Learn how they used Liquid Crystal Magna and BASF Forward AM Ultracur3D® Daylight resin.