3D printing solutions

Orthotics

Printing orthotics requires exacting physical properties tailored to the application, and also very fast printing.

Liquid Crystal Magna is the fastest, large capacity 3D printer capable of delivering upper and lower limb orthotics.

DL110H resin has the properties to print rapidly and reliably and provides the user with a comfortable, skin-safe, strong and durable cast.

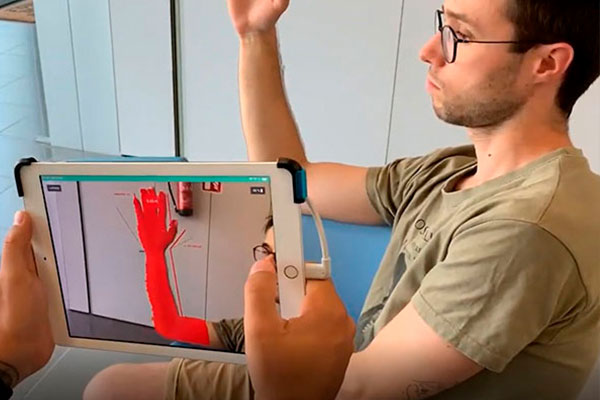

Xkelet and Photocentric’s innovative collaboration is transforming the way bone fractures are treated worldwide.

The powerful alliance has seen the creation of an advanced solution to traditional orthotics; one which is revolutionising the treatment of damaged bones.

The bespoke 3D printing technology combined with Xkelet’s cutting-edge AI software has a twofold effect, improving treatment procedures for the health provider and dramatically advancing patient recovery.

How Xkelet and Photocentric’s innovative collaboration is transforming the way bone fractures are treated worldwide.

The powerful alliance has seen the creation of an advanced solution to traditional orthotics; one which is revolutionising the treatment of damaged bones.

The bespoke 3D printing technology combined with Xkelet’s cutting-edge AI software has a twofold effect, improving treatment procedures for the health provider and dramatically advancing patient recovery.

The challenge

Slow production and high costs

Originally using FDM 3D printers which were too slow, taking at least 10 hours to produce the required patient casts; unsuitable in an industry where demands dictate speed and efficiency. Xkelet faced production, time and cost challenges. Unable to manufacture casts quickly and at a low cost, experimenting with other 3D printing technologies proved unsuccessful until the arrival of Liquid Crystal Magna.

The solid and closed design of traditional limb casts eliminate any opportunity for the prescriber to examine the injury and check for progress, potential swelling, or infection throughout recovery. Heavy, uncomfortable, and hindering everyday life, traditional designs often lead to further discomfort as sores are prone to develop.

The solution

Liquid Crystal Magna

Tailored to Xkelet’s application the XKprinter was shaped. An application tailored Liquid Crystal Magna printer with modified hardware and firmware, the XKprinter is supported by an optimised material, required for Xkelet’s innovative 3D printed cast solutions.

Made to measure with their cutting-edge XKSO 3D scanning software, today Xkelet’s 3D printed affordable, personalised and lightweight cast alternative to plaster, thermoplastics and other orthotics has been adopted in 17 countries worldwide.

In a single print run Xkelet can rapidly produce more than 10 braces vertically and the large build volume also supports the fabrication of larger casts, such as leg orthotics.

Quicker production process

Customisable braces produced 10 times quicker

A customised lightweight, holed brace printed on LC Magna, providing vital ventilation and a patented open/close lock system for easy fitting and swift removal, whilst providing maximum comfort to the patient.

It takes just 30 seconds for a limb to be scanned with Xkelet’s XKSO software; an all-encompassed program built for health professionals by health professionals. 2 minutes later, the scan has been fully processed, fabricating a virtual 3D patient specific cast. Converted into a stl file, the cast transforms into its physical form layer by layer with LC Magna’s cutting-edge 3D printing technology

“We now have a solid and reliable way of turning our products into reality thanks to our collaboration with Photocentric and their unique technology. Our business is built on helping people and that’s exactly what our partnership enables us to do. We can now provide an advanced 3D printed solution to traditional orthotics globally, at a cost and speed unknown before”

Jordi Tura

Owner Xkelet