3D printing solutions

Figurines & Models

Our high-resolution printers deliver the optimised solution for making figurines and models. With 10 years of experience making highly detailed figurines and models, we can help you create everything from one-offs to hundreds of thousands of pieces.

Our resins deliver the best appearance and give you the confidence that they can be stuck, painted and won’t break.

Model size: 600mm (w) x 300mm (d) x 380mm (h)

Just the ticket! cirp keep model railway enthusiasts on track.

modellbahn.blog wanted a new aftermarket product for model locomotives, very small loudspeakers to enhance the audio capability of their model locomotives, sitting in the chassis and integrating with the existing electronics.

cirp identified Magna as the obvious choice. With its speed, build volume and access to a range of high-performance materials, Magna and BASF Ultracur3D® Daylight resin was selected. In less than 8 hours 1000 highly detailed parts were produced in over 20 variations.

Utilising Magna to make amazing Boulder Dash model characters

3D w praktyce wanted to make Boulder Dash model characters for a short stop-frame animation using a 3D printed version of Rockford. It was formed using Photocentric Studio and printed on Magna. The large build volume made it possible to create not just one Rockford, but a whole army of them, in a single print.

Staples & Vine

Overcoming production challenges with the adoption of 3D Printing

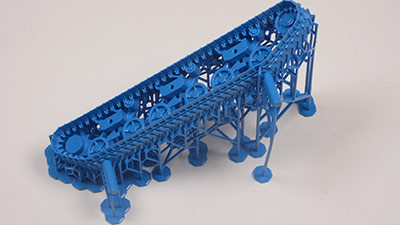

Staples & Vine push the boundaries of what is possible in collectable model industry. When they wanted to make lots of highly detailed tank and aircraft models they turned to Magna.

Hover to view details

Model: 65cm (h) x 45cm (w)

Printed on Liquid Crystal Magna

Just the ticket! cirp and Photocentric keep model railway enthusiasts on track.

Railway modelling continues to be a very popular hobby – in Europe, famous brands including Hornby, ROCO, Marklin, Bachmann, Walthers and Piko dominate the market. In Germany, cirp, a 3D Printing Bureau were approached by modellbahn.blog, a specialist online model railway retailer that offers service and a wide range of spares and accessories to model railway enthusiasts.

The team at modellbahn.blog came up with an idea to create a new aftermarket product for model locomotives. They saw an opportunity to create very small loudspeakers that would add audio or enhance the existing audio capability of the model locomotives. These loudspeakers would be designed to sit within the chassis of the locomotive models and integrate with the existing electronics.

Challenge

For the project to be successful it was imperative to be able to repeatedly produce very small parts consistently with precise details such as drill holes and pins for electronic components. In addition, several variants were required for different locomotive models. For large volumes of parts, injection moulding would be the obvious manufacturing solution, but at far lower volumes the cost of tooling was prohibitive. In order to keep this project on track another solution was required.

Solution

With their knowledge of Photocentric printers and materials, cirp identified the Photocentric LC Magna as the obvious choice. With its speed, build volume and access to a range of high-performance materials, the LC Magna was perfect. BASF Forward AM Ultracur3D® Daylight resin was chosen as the material. In less than 8 hours nearly 1000 highly detailed parts were produced in over 20 variants. The result meant that modellbahn.blog were able to provide their passionate model railway customers with an ingenious sound experience product in no time at all.

3D w praktyce utilise Magna to make amazing Boulder Dash model characters

Boulder Dash is a 2D maze-puzzle video game that was originally released in 1984 for the Atari 8-bit range of computers. The Commodore 64 version of the game is still regarded as one of the best games to ever be released on this platform. In the game, players guide the character, Rockford around a series of caves to collect as many diamonds and other treasures as possible, whilst avoiding hazards.

As an homage to this classic game, 3D w praktyce were tasked with creating a short stop-frame animation. For this animation, a 3D print-ready file of the character Rockford was created using Photocentric Studio which was then printed on the LC Magna. Given the large build volume of the LC Magna it was possible to create not just one Rockford, but a whole army of Rockford characters in one single print run.

Manufactured with the Photocentric High Tensile White Resin material, the figures were strong and durable, yet incredibly detailed and accurate. After a simple post processing process the characters were painted and were then ready for filming. The animation has gone on to receive considerable acclaim from avid fans of the game and you too can watch the short version.

Staples and Vine

Established in the UK in 1996, the Staples & Vine Ltd story began with a 1:144 scale copy of Bristol Blenheim Mk IV. As time passed and their craftsmanship developed, their passion and drive transformed the company into the highly regarded military model business that it is known as today.

Staples & Vine continue to develop new models; adding to their already assorted military collection, to raise their public profile as a leading worldwide manufacturer of pewter aircraft and tank models.

Whilst all models continue to be hand designed and manufactured by Sera Vine (founder of Staples & Vine) at their studio in Devon, Sera’s take on the entire process has changed through discovering new technologies. Staples & Vine’s vision is to continuously push the boundaries of the collectable modelling industry and overcome the challenges faced during the design and production stages. For this reason, the tank and aircraft model manufacturer decided to build the advanced capabilities of 3D printing into their progressive work.

Challenge

Limitation of high detail

Traditional methods of hand sculpting on highly detailed subjects hindered the level of accuracy and time taken to create models. Introducing 3D printing into their workflow reduced the time taken to create highly detailed models, delighting customers with scaled replicas that truly reflected original military designs.

Inaccurate masters

Staples & Vine produce their master models through a vulcanisation process. These masters are then used to build multiple replicas of an original military design. The challenge faced was that the material used to build their masters was unable to withstand the heat and pressure during this process; resulting in Staples & Vine producing inaccurate masters to work from.

Results

Freedom to design with unlimited detail

With the integration of 3D printing into their workflow, Staples & Vine can now produce highly detailed 3D replicas of their original military designs.

Production time reduced by 25%

By using the LC Precision 1.5 they are able to condense the stages of production making it easier for them to bring a new product to market. All of these benefits have come together to offer a collective time saving of 25% to them as the manufacturer, this is a drastic saving when compared to other leading 3D printing technologies that were only able to save just 15% on time.

High quality masters produced

By 3D printing their designs in Daylight Precision Mould resin, Staples & Vine are able to bring to life high-quality, accurate master models with ease. These models can then be vulcanised thus allowing them to mass manufacture highly-detailed copies to sell onto their customers.