LC Magna

Large Format Industrial LCD 3D Printer

A printing workhorse built to last. Large build volume, industrial performance, dependable and reliable, large range of functional resins make Magna the machine that has made millions of parts. Proven technology, proven results.

It Just Works

Industrial Production

Designed to go on for life. Dependable performance making mass production parts.

Large Volume

510 x 280 x 350 mm (20 x 11 x 13 3/4”) build volume.

Fast Printing

Up to 86mm/hr at 350μm layers.

Technical

Specification

Large Build Volume

510 x 280 x 350mm

20 x 11 x 13 3/4”

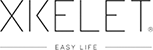

Blow-Peel Technology

Patented technology ensures reliable, fast printing

High Resolution Pixel Pitch

137μm pixel pitch delivers outstanding finish

Fast Printing

Up to 86mm/hr at 350μm layers

ResinGlide Platform

Interchangeable easy clean, low waste platform

Long-lasting Screen

No-UV degradation

Energy Efficient

11% of the energy per printed kg of equivalent FDM parts

The Complete Magna Processing System

Photocentric’s Air Wash L and Cure L2 work in synergy with LC Magna to streamline post-processing for industrial-grade results – delivering efficient cleaning and precision curing for ready-to-use, mechanically stable parts.

Wide Range of Functional Resins

From elastomeric to certified flame retardant resins for a range of industries creating functional high-definition parts.

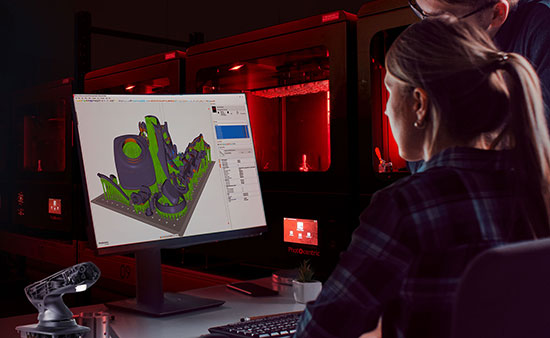

Software

Photocentric Studio and Voxel Dance deliver full large file part preparation and printer user interface, from design to production.

Support

On-site installation and training, service plans, warranties, and full Design for Additive Manufacturing technical support available from personal and online service.

Our team of 3D printing and material science experts are always available to you.

Print Smarter:

Reduce Costs and Accelerate Production

Handles

Print Time: 11h 16mins

Resin: DL110

Length: 155mm

Weight: 46.5g

Supports weight: No supports required

Resolution: 100µm

Saber-Toothed Tiger Skull

Print Time: 30h 30mins

Resin: DL110

Height: 310mm

Weight: 715g

Support Weight: 150g

Resolution: 100µm

“Saber-Toothed Cat Skull” by MakerBot, licensed under Creative Commons (CC-BY-SA-4.0) License

Titan Handles

Print Time: 10h 43mins

Resin: DL110

Height: 180mm

Weight: 290g

Support Weight: 179.5g

Resolution: 100µm

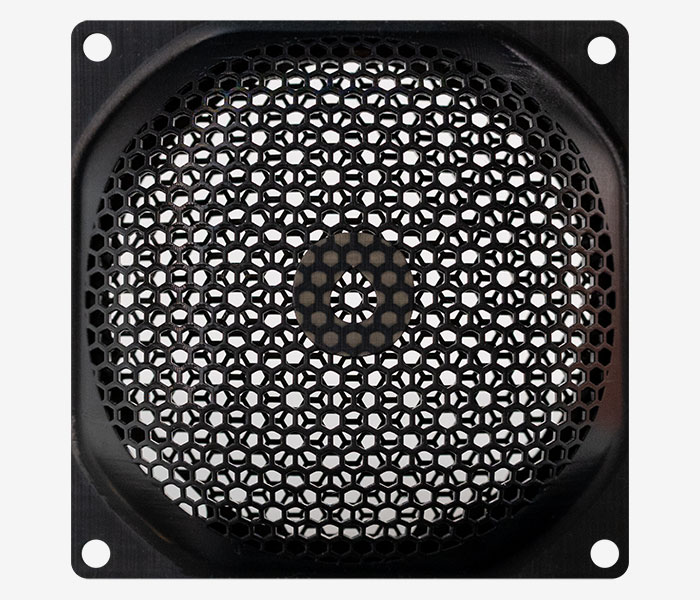

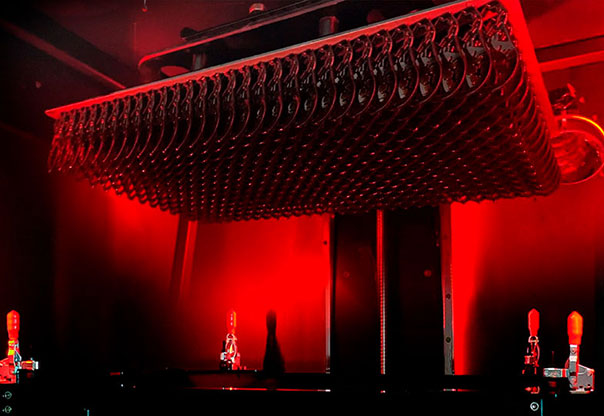

Magna Carbon Filters

Print Time: 7h 3mins

Resin: Hard Black

Height: 92mm

Weight: 28.5g

Support Weight: No supports required

Resolution: 100µm

Speakers

Print Time: 8h 56mins

Resin: DL110

Height: 200mm

Weight: 480g

Support Weight: 42g each

Resolution: 100µm

Support

On-site installation and training, service plans, warranties, and full Design for Additive Manufacturing technical support available from personal and online service.

Our team of 3D printing and material science experts are always available to you.

Total Cost of Ownership (TCO):

See the Full Picture

The costs of a 3D printer go beyond the purchase price

We believe in complete cost transparency, so we include waste, labour, consumables, materials, maintenance, energy use, in fact everything in our TCO.

Printer Comparison

Customer Testimonials

“This is a huge step in the development of manufacturing to replace injection molding as we see large companies replacing their current manufacturing processes with additive manufacturing parts”

Spencer Loveless, Merit 3D CEO

“3D printing with Magna is going to change fundamentally the way we bring moulds and products to the market. HighTemp DL401 is very good for us because it reaches the higher temperatures necessary for PU injection and keeps them stable”

Giovanni Grigolato, Head of R&D at Grisport

“We could not believe the huge savings brought by 3D printing. The cost of Photocentric’s technology was 80-90% cheaper, a far cry from expensive Injection Moulding costs, even for larger injection series where savings will still be around the 60-70% mark. Equally astonishing was the shorter life cycles, we saved 30% on lead times”

Carlos, Tetralogia

“We got quotes and tested almost every printer in the market for dental applications and no one matched the cost benefit. Photocentric LC Magna was the only printer we analysed that could produce 48 models in 90 minutes. The Magnas are extremely fast, accurate and have a great cost-benefit for both hardware and resin. No one else came even close.”

Michael Ruah Co-founder, SouSmile

“We now have a solid and reliable way of turning our products into reality thanks to our collaboration with Photocentric and their unique technology. Our business is built on helping people and that’s exactly what our partnership enables us to do. We can now provide an advanced 3D printed solution to traditional orthotics globally, at a cost and speed unknown before”

Jordi Tura, Owner Xkelet

Book a Consultation

Want to explore large format, high resolution printing with Magna, schedule a call with our experts.

We’ll use these details to keep you up to date with Photocentric news and insights. You can unsubscribe at any time. View our Privacy Policy for more details.

97%

UK Precision Engineering at Our Core

Liquid Crystal Magna is designed and assembled in the UK with 97% UK sourced components.

Related Resources

Wurtec’s additive manufacturing breakthroughs with LC Magna

>

Grisport is an Innovative Italian shoe manufacturer who wanted to improve their margins and go to market quicker

>

Merit3D 1 million 3D printed part order for Adhesives Technology with LC Magna

>

Bohanna Art meticulously craft sculptures and art pieces with LC Magna

>

VXL Technologies helps Railex increase functionality and efficiency of garment conveyor system

>

Xkelet and Photocentric’s Innovative collaboration is transforming the way bone fractures are treated worldwide

>

SouSmile opts for Photocentric Liquid Crystal Magna 3D printer

>

![Crack-Eraser-Automotive-Case-Study-Magna]](https://photocentricgroup.com/wp-content/uploads/2025/04/Crack-Eraser-Automotive-Case-Study-Magna.jpg)

Crack Eraser solves windshield repair woes with Photocentric LC Magna

>

As a manufacturer of equipment for laundry services, Girbau sought to improve the efficiency of their folding machines using LC Magna

>