Mass Production Parts Service

Our on-site 3D print farm enables mass manufacturing, on demand, without tooling delays.

Access the capabilities of our unique LCD 3D printing facility and scale up your manufacturing cost-effectively and without the need for in-house equipment.

Our Offering

Our service allows you to transition from prototyping to full scale mass manufacturing in a matter of days.

Unmatched Scalability

Scale up your production without

sacrificing on quality

Unbeatable Build Volume

Our LC Titan is the world’s largest

LCD 3D printer

Industry Leading Technology

Home to JENI, the world’s first autonomous

digital mass manufacturing machine.

Made with Precision

Parts produced to your precise

specifications

Reliable Turnaround

High throughput with fast lead times for on-demand production.

Quality Assured

ISO 9001 certified

Industries Served

Our services are trusted by clients in a wide range of industries including:

Arts & Entertainment

Automotive

Consumer Goods

Healthcare & Medical

Industrial Parts

Miniatures

Sports Goods

Tooling

Print Examples

Handles

Print Time: 11h 16mins

Resin: DL110

Length: 155mm

Weight: 46.5g

Supports weight: No supports required

Resolution: 100µm

Saber-Toothed Tiger Skull

Print Time: 30h 30mins

Resin: DL110

Height: 310mm

Weight: 715g

Support Weight: 150g

Resolution: 100µm

“Saber-Toothed Cat Skull” by MakerBot, licensed under Creative Commons (CC-BY-SA-4.0) License

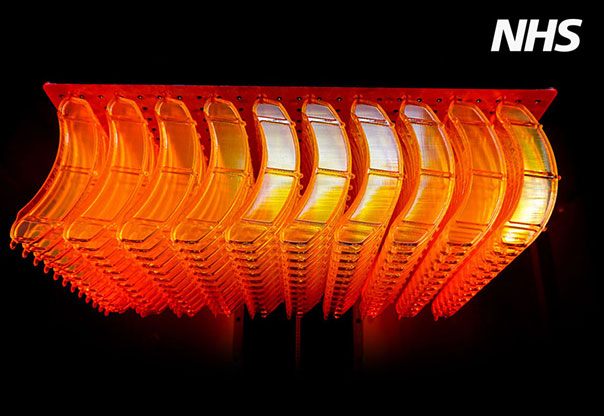

Titan Handles

Print Time: 10h 43mins

Resin: DL110

Height: 180mm

Weight: 290g

Support Weight: 179.5g

Resolution: 100µm

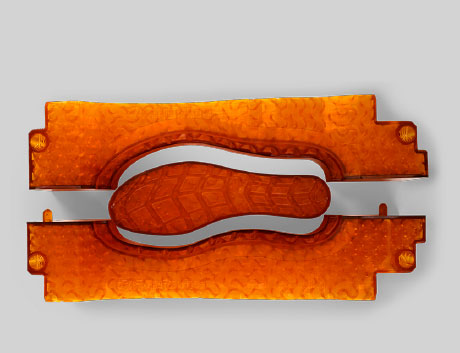

Magna Carbon Filters

Print Time: 7h 3mins

Resin: Hard Black

Height: 92mm

Weight: 28.5g

Support Weight: No supports required

Resolution: 100µm

Speakers

Print Time: 8h 56mins

Resin: DL110

Height: 200mm

Weight: 480g

Support Weight: 42g

Resolution: 100µm

The only production parts service of its kind

Over 10,000,000 Parts

Produced to Date

Our facilities offer you unmatched volume and scalability. Our machines are designed, engineered and produced in the UK.

Our wide range of functional materials allow us to cater to your manufacturing needs and ensure your parts have the properties required to meet your specifications. We formulate and produce a wide range of functional resins in the UK, in the same facility that will transform your manufacturing. Combining our range of specialist 3D printers and functional resins enables high detailed and precise manufacturing. Producing quality parts consistently and effectively.

Rigid

Durable

Flexible

Flame Retardant

Castable

The world’s first autonomous digital mass manufacturing machine, leading the charge in Industry 4.0.

The largest LCD 3D printer in the world, built for high-resolution, large-scale outputs.

High-resolution, industrial-grade LCD 3D printer, designed for precision and production efficiency.

Production Made Simple

1

Request a quote and consultation

Our service allows you to quickly upload your specifications and requirements. As well as book in an initial consultation with a member of the team who will provide expert advice for the most effective approach to your requirements.

2

Converting your design and produce samples

Our team of design specialists will then apply their additive manufacturing design techniques to improve the performance, appearance and printability of your part. Samples can then be made and delivered to you.

3

Production

Your parts are then printed using our premium resin on either

- Our LC Titan farm. LC Titan is the world’s largest LCD 3D printer

- Our LC Magna farm, which is responsible for printing millions of end use parts

- JENI, the world’s first fully automated mass additive manufacturing platform.

4

Quality Control and Distribution

Once completed, your parts are inspected to ensure they meet your specifications exactly and are then dispatched to you.

Expert Design Support

Our team of 3D design specialists will convert your CAD design and enhance the performance, appearance and printability of your part where necessary.

We ensure the printability of your designs and are set up for print success.

Request a Quote

We’ll use these details to keep you up to date with Photocentric news and insights. You can unsubscribe at any time. View our Privacy Policy for more details.