imagepac – The world’s first photopolymer pack

The most efficient way to make polymer stamps

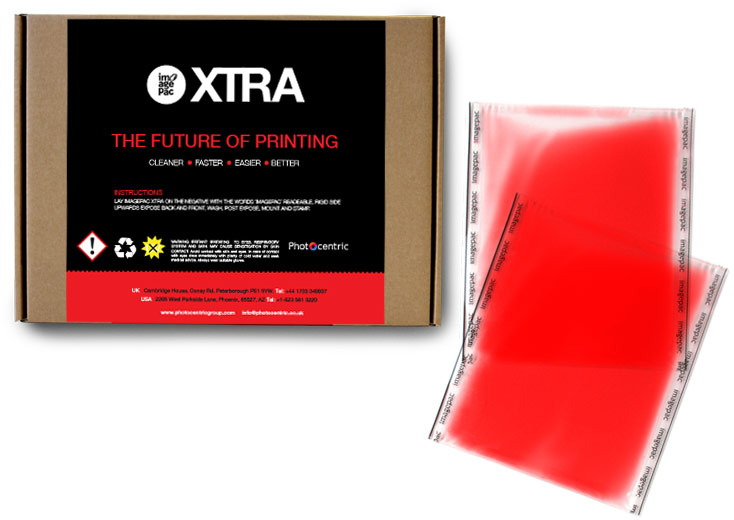

What is imagepac Xtra?

In 2002 we created the world’s first photopolymer pack for stamp making. Over the years we have developed it into the most efficient way to make polymer stamps possible. We called it imagepac xtra and this self-contained, ready-to use pouch has revolutionised stamp making over the last 15 years.

Advantages of imagepac Xtra

- Improves quality delivering consistent production with less stamp-to-stamp variation.

- Lower cost with less waste and less labour.

- Increased capacity by doubling machine utilisation.

- Simpler process making it easy to delegate the process to other staff.

- Less ancillaries to stock control replacing polymer, backing sheet, damming tape and coverlay.

- Faster saving on average 10 min per plate.

- Cleaner as there is no spill, no pouring required.

Pouring bottled resin in comparison to imagepac xtra

It is a simple idea that makes such a big difference. Using only the resin you want, pre-poured and optimized in a package just right for your application. It eliminates numerous steps from the traditional stamp making process.

Watch the comparison below.

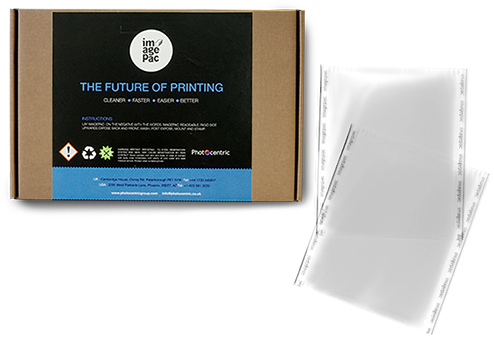

What is imagepac superclear?

imagepac superclear is pre-packaged 50 durometer photopolymer in a sachet. One side of the sachet is rigid, aiding handing during processing and the other is flexible, delivering excellent imaging.

Benefits over pouring photopolymer

It is a simple idea that makes such a big difference. Using only the resin you want, pre-poured and optimized in a package just right for your application. It eliminates numerous steps from the traditional stamp making process.

-

No pouring resin

-

No mess

-

No bubbles

-

No laying of film, tape or pouring resin, saving over 10 minutes per plate. Typically 30% less waste.

-

Reduces your inventory

-

Easier to use, can delegate process.

Recommended use

imagepac superclear is ideally suited for making craft stamps or for business stamp applications where you want to mask to produce large numbers of the same sized pre-cut stamps.

Ink compatibility

Water, oil and glycol based.

Sachet sizes

Inner seal | Sachet size

A3- 306 x 436mm | 301 x 431mm

A4- 217 x 301mm | 212 x 301mm

A6- 107 x 140mm | 104 x 137mm

A7- 107 x 74mm | 104 x 71mm

A3, A4 & A6 packed in 5’s | A7 packed in 10’s