What is 3D Printing?

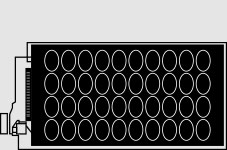

Liquid Crystal Displays

The concept we invented. Using an LCD screen as a light source, an entire layer is encoded simultaneously, rather than small area by area. LCD printing benefits from one of the greatest technological advances of the last 50 years the use of visual display screens. It can produce much larger volumes than alternative methods, creating new products at rates previously unimaginable. The simplicity of the process is its strength, if using daylight as opposed to UV, the exposure is even and the machine stable for many years of use.

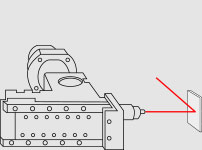

Laser

The laser beam cures liquid photopolymer resin at very high resolution. However, because of the necessity to create each part voxel by voxel this is a time-consuming process. The laser and its galvanometer require regular calibration and replacement.

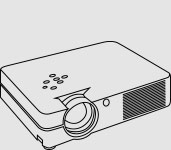

Digital Light Projectors

DLP projectors became a widely used alternative to lasers being able to cure a much larger area the size of a mobile phone screen at 2k and 4K resolutions. The bulb and Digital Mirror Device need replacing and calibrating. Even though it can cure an area larger than a laser beam, it cant match an LCD for resolution, reliability or cost.

When to choose 3D printing?

3D printing is increasing rapidly in industry, early adopters have gone from strength to strength and have seen the benefits first-hand of how additive manufacturing can assist their production lines.

Where 3D printing was once seen as suitable merely for prototyping and one-off products, it is now essential to production.

Widely used as an investment casting approach, it has huge benefits in reducing the costs of traditional methods of tooling for injection moulding.

As the technology continues to evolve, additive manufacturing promises to revolutionise all industries and shape the way we work, play live and travel for the future.

Why use 3D printing over Injection Moulding?

Budget

Initial tooling for injection moulding can be expensive – avoid the initial outlay associated with traditional manufacturing techniques by choosing our 3D printing service or 3D printers.

Customisation

Additive Manufacturing offers a freedom of design not possible with injection moulding or subtractive manufacturing. Furthermore, with no mould fees, customisation becomes an easy option

Simplicity

3D Printing enables manufacturers to continuously adapt their range, improve product performance, reduce weight and consolidate multiple parts into one. Enabling them to decrease SKU numbers and easily enhance their offering continuously.

Flexibility

The 3D printing process offered by Photocentric enables customers to make as many alterations as required or changes to prints throughout the production, without being tied to additional charges for amends or retooling.

Speed

At Photocentric, we pride ourselves on our quick turnaround times, combined with the ease of the 3D printing process, you really can go from concept to market in a matter of days.

Volume

Photocentric 3D print services enable you to make low-volume personalised manufacturing accessible at any time or to support peak times when mass manufacturing is urgently required to support your traditional process.