3D printing solutions

Industrial parts

To be successful at making parts, as opposed to prototypes, you need fast, cost-effective, reliable printing processes with functional resins.

Photocentric’ s LCD technology enables lots of parts to be printed very quickly. Our software and design for Additive skills enable the parts to be designed for mass-manufacture.

Our resins deliver functional parts that will last for decades in industrial applications.

Solving solves windshield repair woes with Photocentric LC Magna

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser – which helps other entrepreneurs start their own auto glass repair businesses – to develop a part for its repair kit system.

The proprietary technology has helped Crack Eraser to solve the most challenging aspect of windshield repair, that of drilling into the top layer of laminated windshield glass at the point of impact where damage occurred.

“The 3D Printing Store was invaluable in supporting us in development of this industry leading product through months of testing and refinement. We can’t thank the 3DPS enough for their outstanding support in the development of our industry leading 3D printed Drill Stop Collet™!”

Tim Evans

Owner, Crack Eraser

Phone Skope focuses on LC Magna solution to solve manufacturing challenge

Digiscoping leader, Phone Skope, has adopted a Photocentric additive manufacturing solution to manufacture its custom-moulded digiscoping adaptors. The US-based manufacturer makes precision engineered adaptors for almost any smartphone, enabling a smartphone camera to capture enhanced images and video through a scope for birding, wildlife, microbiology and astrology applications.

““The speed and agility of additive manufacturing has given us the ability to expand coverage for more phones giving us a larger market to pursue”

Jason Bairett,

Operations Manager, Phone Skope

1,000,000 3D Printed Part Order For Adhesives Technology

Merit3D, empresa líder en fabricación aditiva, está produciendo 1.000.000 de perchas para Adhesives Technology mediante tecnología de impresión 3D. Las perchas son necesarias para cada proyecto que emprende Adhesives', pero el proceso de producción se detuvo debido a la falta de disponibilidad de la herramienta de moldeo por inyección.

La solución de Merit3D ayudó a Adhesives Technology a eliminar el coste adicional y el tiempo de espera para la entrega de una nueva herramienta y a devolver la fabricación a Estados Unidos.

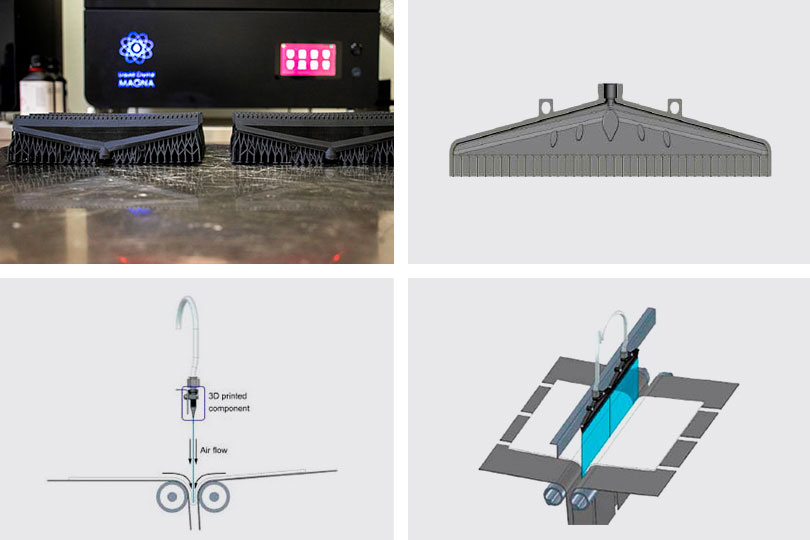

Adaptarse e innovar con la impresión 3D

Como fabricante de equipos para servicios de lavandería, Girbau buscaba mejorar la eficiencia de sus plegadoras. Al darse cuenta de que el flujo de aire de su plegadora no era óptimo para el plegado de precisión que necesitaban, Girbau recurrió a la impresión 3D por la velocidad, la eficiencia, las posibilidades de diseño ilimitadas y la rentabilidad de esta tecnología para crear la pieza de solución única que necesitaban para optimizar sus plegadoras.

"Los expertos de Sculpteo nos apoyaron durante todo el proceso de impresión para que pudiéramos seguir adelante e imprimir el modelo con la mejor solución que se ajustara a nuestros retos".

Sylvian Ferris

R&D Designer, Girbau

Adaptarse e innovar con la impresión 3D

Como fabricante de equipos para servicios de lavandería, Girbau buscaba mejorar la eficiencia de sus plegadoras. Al darse cuenta de que el flujo de aire de su plegadora no era óptimo para el plegado de precisión que necesitaban, Girbau recurrió a la impresión 3D por la velocidad, la eficiencia, las posibilidades de diseño ilimitadas y la rentabilidad de esta tecnología para crear la pieza de solución única que necesitaban para optimizar sus plegadoras.

Desafíos

1. Rediseño de una pieza dentro de una plegadora manteniendo un precio competitivo.

2. Utilizar un material lo suficientemente fuerte como para crear pequeñas cavidades dentro de la pieza para soportar la alta presión.

Solución

Optimización de la geometría interna para mejorar las prestaciones

Con la optimización de las geometrías interiores de la pieza, la cantidad de aire a presión necesaria para cumplir su función se redujo de 5,5 bares a 4 bares, lo que se tradujo en un menor consumo de aire y en una máquina más sostenible. Los pequeños canales creados dentro de la pieza para dirigir el flujo de aire redujeron significativamente el impacto sonoro de la máquina. Antes, con la pieza básica de tubo perforado, el flujo de aire no tenía una dirección precisa y el único túnel se hacía eco del sonido de la presión del aire.

Mejor diseño a un precio competitivo

Durante su proceso de diseño aditivo, Girbau fue capaz de diseñar una pieza con geometrías complejas, partes funcionales integradas y ligeras y compactas. La naturaleza aditiva de la tecnología de impresión 3D significa que la creación de una pieza compleja no tiene un precio más alto y, de hecho, a veces puede ser más barato ya que se utiliza menos material. Con estas posibilidades de diseño, Girbau pudo crear una pieza de solución única que era rentable. Esto no habría sido posible con los métodos de fabricación tradicionales, ya que las posibilidades de diseño de la fabricación tradicional requieren moldes caros y grandes volúmenes de producción para compensar el coste.

Aprovechar al máximo las funciones integradas

La simplificación de su pieza, que ahora tenía funciones integradas como soportes que permitían fijar fácilmente su pieza a un bastidor dentro de la plegadora. Un modelo más compacto que no sería posible encontrar en el mercado o difícil de crear con los métodos de fabricación tradicionales.

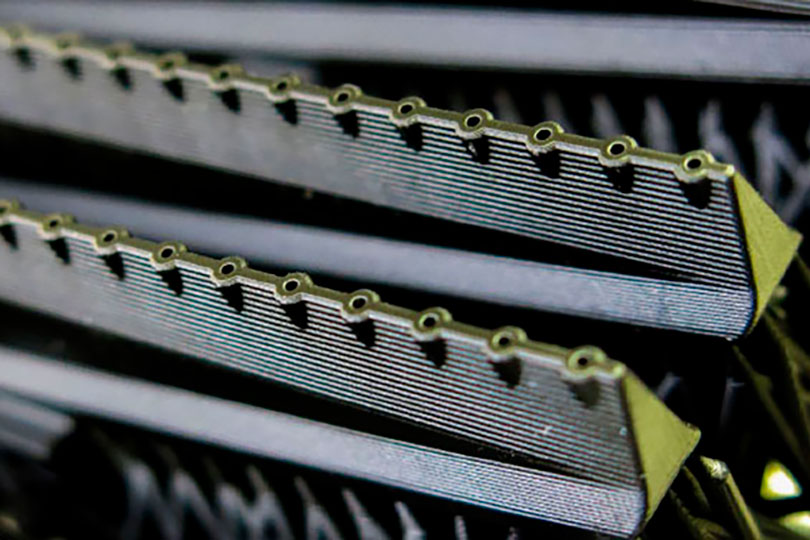

Ultracur3D® EPD 1006 y LC Magna : La precisión necesaria para afrontar los retos de fabricación

With a final design, Girbau turned to Sculpteo’s online printing service to create a prototype that would potentially be the final part for their machines. They decided on SLS (selective laser sintering) technology and Nylon PA12 material. When testing the part, they realised that there was excess powder from the PA12 material blocking the airflow. With Sculpteo’s responsive customer support, Girbau was advised to use LCD (Liquid Crystal Display) printing technology to create tiny channels within the part, which powder technology cannot do, using the resin material EPD 1006. Parts printed with resin materials have high accuracy and are perfect for designs that require high precision, like Girbau’s part.

La tienda de impresión 3D resuelve los problemas de reparación de parabrisas con Photocentric LC Magna

The 3D Printing Store (3DPS) ha utilizado Photocentric's LC Magna para fabricar una pinza de perforación a medida, haciendo que la reparación de parabrisas sea más fácil y eficiente que nunca. Photocentric El socio 3DPS fue contactado por Tim Evans y su empresa Crack Eraser - que ayuda a otros emprendedores a iniciar sus propios negocios de reparación de cristales de automóviles - para desarrollar una pieza para su sistema de kit de reparación. La tecnología patentada ha ayudado a Crack Eraser a resolver el aspecto más difícil de la reparación de parabrisas, el de la perforación de la capa superior del vidrio laminado del parabrisas en el punto de impacto donde se produjo el daño. Utilizando Photocentric LC Magna , 3DPS pudo fabricar más de 1.000 pinzas de perforación, dentro de unas tolerancias aceptables, en sólo cinco horas de impresión.

Desafío

El componente de precisión impreso en 3D se utiliza para sujetar el diminuto taladro para cristales que se utiliza en la reparación de parabrisas, y ha hecho que este proceso crítico de taladrado sea rápido, fiable y automático. Antes, aprender la técnica correcta requería formación, mucha práctica, un alto grado de motricidad fina y mucho tiempo para completar una reparación con éxito.

Solución

La nueva pieza ha simplificado el trabajo y permite a los clientes de Crack Eraser hacer el agujero perfecto cada vez. La tienda de impresión 3D dijo que la tecnología Photocentric fue esencial tanto en la fase de prototipado rápido como en la de producción. Pudieron imprimir varias boquillas de perforación para probar la profundidad a la que se apoyaría la broca en cada boquilla, y evaluar si conducía a una reparación satisfactoria del parabrisas. Una vez finalizado el diseño, la producción fue rápida y el procesamiento posterior, mínimo.

"Es muy alentador ver a un empresario innovador como Tim resolviendo retos mediante el uso de la tecnología de fabricación aditiva con nuestro socio The 3D Printing Store", "Con el gran volumen de construcción de LC Magna, es una excelente opción para producir piezas de uso final de forma rápida y eficiente a escala, ofreciendo velocidad, volumen y ahorro de costes a las empresas. La naturaleza intrincada de esta pieza significa que se necesitan herramientas de precisión, y en este caso, LC Magna ha sido capaz de proporcionar una solución ágil y flexible para la fabricación.''

Sally Tipping – New Business Development Director, Photocentric

Phone Skope se centra en la solución Photocentric LC Magna para resolver el reto de la fabricación

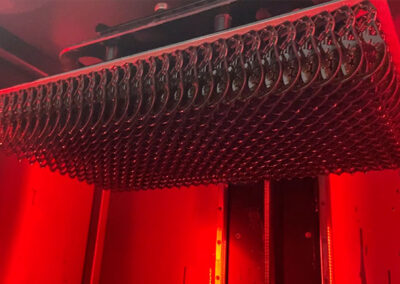

Phone Skope, líder en digiscoping, ha adoptado una solución de fabricación aditiva Photocentric para fabricar sus adaptadores de digiscoping moldeados a medida. El fabricante, con sede en Estados Unidos, fabrica adaptadores de precisión para casi todos los teléfonos inteligentes, lo que permite que la cámara de un teléfono inteligente capture imágenes y vídeos mejorados a través de un visor para aplicaciones de observación de aves, fauna, microbiología y astrología. La solución de fabricación aditiva Photocentric -realizada a través del proveedor de servicios de fabricación Merit3D- incluye las impresoras Photocentric LC Magna y las unidades de posprocesamiento, lo que permite modelar y crear los adaptadores a gran velocidad sin necesidad de un costoso y largo moldeado.

A fast moving market – The Challenge

"La fabricación de Phone Skope se vio dificultada por la rápida evolución del mercado, que exigía que sus productos fueran compatibles con un gran número de nuevos modelos de teléfono que salían al mercado cada año", afirma Sally Tipping, Photocentric. "Para crear un adaptador de digiscoping compatible con un determinado modelo de teléfono, había que crear un molde para cada nueva carcasa, y siempre existía la posibilidad de que el propio teléfono no fuera un éxito comercial. Esto significaba que Phone Skope tenía que elegir entre qué modelos apoyar y crear moldes para mantener la viabilidad. La impresión 3D fue una excelente solución a este problema, ya que proporcionó a Phone Skope la flexibilidad necesaria para sacar al mercado una mayor variedad de adaptadores a gran velocidad, sin las implicaciones económicas que supone la creación de moldes adicionales. Los productos de Phone Skope son conocidos en todo el mundo por su precisión y durabilidad, por lo que también era vital que estas características se mantuvieran sin concesiones."

Photocentric y LC Magna - La solución perfecta

Para producir las cajas, Merit3D utilizó sus 8 impresoras Photocentric LC Magna y las unidades de posprocesamiento Photocentric , las unidades Air Wash L y Cure L2. Merit3D también eligió la resina Daylight Magna Duramax de Photocentric. El diseño de Phone Skope es un sistema simple de dos partes que es intercambiable y funciona con la mayoría de las combinaciones de teléfonos y ópticas. Con sólo un par de pequeños cambios en el diseño del modelo 3D, se pudo diseñar e imprimir una nueva carcasa a gran escala con mínimas revisiones mediante la fabricación aditiva. Esto redujo los costes iniciales y aumentó considerablemente el tiempo de producción, con un resultado constante de alta calidad.

La LC Magna se adapta a una amplia gama de aplicaciones de fabricación, ofreciendo importantes ventajas en cuanto a velocidad de impresión, volumen de construcción y costes. Merit 3D también sabía que las impresiones de alta calidad producidas por la LC Magna reducirían significativamente el tiempo dedicado al acabado final, reduciendo así aún más los costes y aumentando la velocidad de comercialización.

También se utilizó el software Studio dePhotocentricy 4D-additive para incorporar los soportes necesarios para la impresión en el diseño real de las cajas. Dependiendo del tamaño del producto final, una sola plataforma Magna podía albergar hasta 52 maletas. Siguiendo un sencillo flujo de trabajo dentro de sus instalaciones de fabricación, el tiempo de finalización de cada uno de los pedidos oscilaba entre 1 y 2 días. La nueva solución permitió ahorrar miles de dólares en costes de equipamiento en la creación de un molde, y el tiempo para crear un nuevo diseño de modelo de caja también se ha reducido de 1 a 2 meses a sólo dos semanas. Gracias a la solución de AM, también se eliminó por completo el anterior pedido mínimo de 2000 unidades (para que fuera viable).

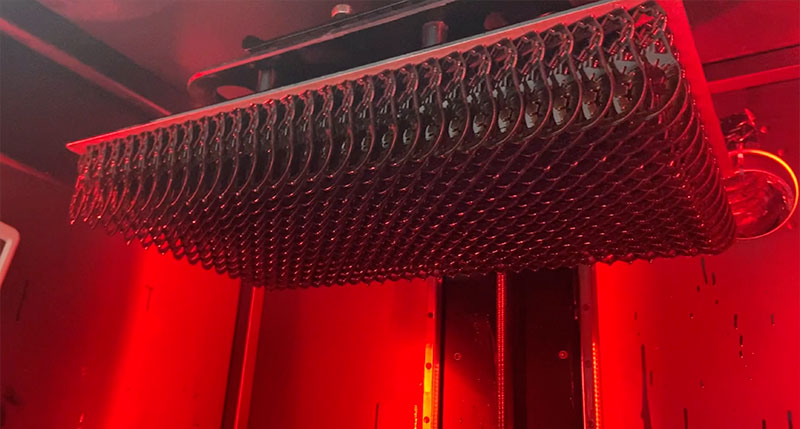

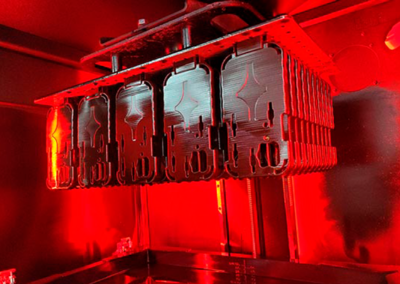

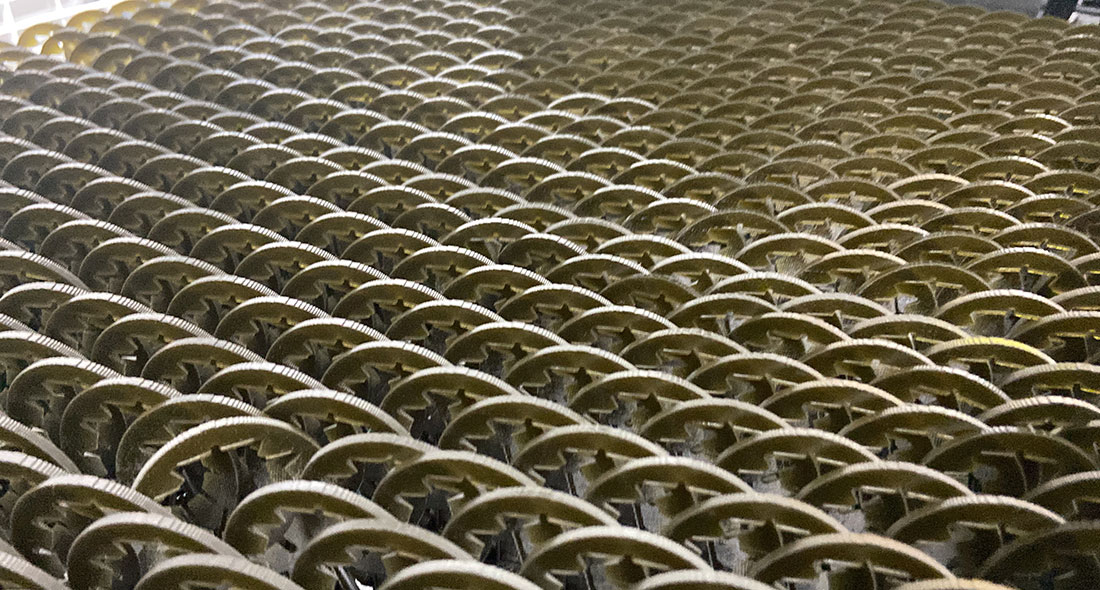

1,000,000 3D Printed Part Order For Adhesives Technology

Merit3D, empresa líder en fabricación aditiva, está produciendo 1.000.000 de perchas para Adhesives Technology mediante tecnología de impresión 3D. Las perchas son necesarias para cada proyecto que emprende Adhesives', pero el proceso de producción se detuvo debido a la falta de disponibilidad de la herramienta de moldeo por inyección.

La solución de Merit3D ayudó a Adhesives Technology a eliminar el coste adicional y el tiempo de espera para la entrega de una nueva herramienta y a devolver la fabricación a Estados Unidos.

The challenge – Access to injection mould tool

Adhesives Technology se enfrentó a una serie de retos debido a los acontecimientos mundiales que impidieron el acceso a su herramienta de moldeo por inyección. La herramienta era necesaria para producir colgadores que mantuvieran unidos los cartuchos de epoxi y las boquillas de mezcla. El proceso de producción se detuvo y la instalación de otra herramienta habría llevado demasiado tiempo, por lo que la impresión en 3D era la única opción viable. Sin embargo, la impresión 3D de los colgadores tendría un coste prohibitivo.

Solution – LC Magna

Merit3D ofreció una solución al reto modificando el diseño del molde y optimizándolo para la fabricación aditiva. En concreto, la empresa optimizó el diseño para las impresoras Magna Liquid Crystal de Photocentric. El proceso de rediseño iterativo de Merit3D duró un total de dos semanas y dio como resultado un diseño que podía imprimirse en 3D de forma eficaz y rentable.

Merit3D utilizó 20 impresoras para producir las perchas, con 400 perchas por plataforma, tardando 225 minutos por plataforma. El material utilizado fue Ultracur3D® EPD1006 de Photocentric y BASF ForwardAM, que ofrecía las propiedades ideales y superó la brutal prueba de durabilidad.

Eliminating costly injection mould tool

La solución de fabricación aditiva de Merit3D permitió a Adhesives Technology seguir trabajando con el pedido de 1.000.000 de perchas, eliminando la necesidad de una costosa herramienta de moldeo por inyección. La solución de la empresa también permitió personalizaciones y múltiples iteraciones de diseño para optimizar las perchas para su uso específico. El uso de la tecnología de fabricación aditiva también redujo los residuos y disminuyó la huella de carbono.

Photocentric's Liquid Crystal Las impresoras Magna resultaron ideales para la fabricación en volumen debido a su gran formato, alto acabado superficial, producción rápida, resinas rentables y funcionales, y bajo consumo de energía.

El éxito de Merit3D en la producción de 1.000.000 de perchas mediante la tecnología de fabricación aditiva demuestra el potencial de esta tecnología para la producción a gran escala. Gracias a la optimización del diseño para la impresión 3D y a la utilización de las impresoras Magna Liquid Crystal de Photocentric, la empresa es capaz de producir las perchas de forma eficiente y rentable.