3D printing solutions

Industrial parts

To be successful at making parts, as opposed to prototypes, you need fast, cost-effective, reliable printing processes with functional resins.

Photocentric’ s LCD technology enables lots of parts to be printed very quickly. Our software and design for Additive skills enable the parts to be designed for mass-manufacture.

Our resins deliver functional parts that will last for decades in industrial applications.

Solving solves windshield repair woes with Photocentric LC Magna

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser – which helps other entrepreneurs start their own auto glass repair businesses – to develop a part for its repair kit system.

The proprietary technology has helped Crack Eraser to solve the most challenging aspect of windshield repair, that of drilling into the top layer of laminated windshield glass at the point of impact where damage occurred.

“The 3D Printing Store was invaluable in supporting us in development of this industry leading product through months of testing and refinement. We can’t thank the 3DPS enough for their outstanding support in the development of our industry leading 3D printed Drill Stop Collet™!”

Tim Evans

Owner, Crack Eraser

Phone Skope focuses on LC Magna solution to solve manufacturing challenge

Digiscoping leader, Phone Skope, has adopted a Photocentric additive manufacturing solution to manufacture its custom-moulded digiscoping adaptors. The US-based manufacturer makes precision engineered adaptors for almost any smartphone, enabling a smartphone camera to capture enhanced images and video through a scope for birding, wildlife, microbiology and astrology applications.

““The speed and agility of additive manufacturing has given us the ability to expand coverage for more phones giving us a larger market to pursue”

Jason Bairett,

Operations Manager, Phone Skope

1,000,000 3D Printed Part Order For Adhesives Technology

Merit3D, azienda leader nella produzione additiva, sta producendo 1.000.000 di grucce per Adhesives Technology utilizzando la tecnologia di stampa 3D. Le grucce sono necessarie per ogni progetto di Adhesives, ma il processo di produzione è stato interrotto a causa dell'indisponibilità dello strumento di stampaggio a iniezione.

La soluzione di Merit3D ha aiutato Adhesives Technology a eliminare i costi aggiuntivi e i tempi di attesa per la consegna di un nuovo strumento e a riportare la produzione negli Stati Uniti.

Adattarsi e innovare con la stampa 3D

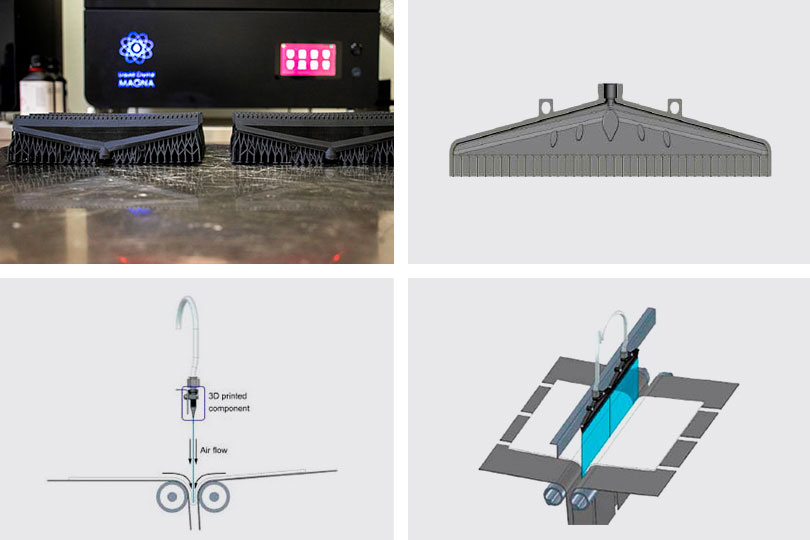

In qualità di produttore di attrezzature per i servizi di lavanderia, Girbau ha cercato di migliorare l'efficienza delle proprie macchine piegatrici. Rendendosi conto che il flusso d'aria della loro piegatrice non era ottimale per la precisione di piegatura richiesta, Girbau si è rivolta alla stampa 3D per la velocità, l'efficienza, le possibilità di progettazione illimitate e l'economicità di questa tecnologia per creare il pezzo unico di cui avevano bisogno per ottimizzare le loro piegatrici.

"Gli esperti di Sculpteo ci hanno supportato durante tutto il processo di stampa, in modo da poter procedere alla stampa del modello con la soluzione migliore per le nostre sfide."

Sylvian Ferris

R&D Designer, Girbau

Adattarsi e innovare con la stampa 3D

In qualità di produttore di attrezzature per i servizi di lavanderia, Girbau ha cercato di migliorare l'efficienza delle proprie macchine piegatrici. Rendendosi conto che il flusso d'aria della loro piegatrice non era ottimale per la precisione di piegatura richiesta, Girbau si è rivolta alla stampa 3D per la velocità, l'efficienza, le possibilità di progettazione illimitate e l'economicità di questa tecnologia per creare il pezzo unico di cui avevano bisogno per ottimizzare le loro piegatrici.

Sfide

1. Riprogettazione di un componente di una macchina piegatrice mantenendo un prezzo competitivo.

2. Utilizzando un materiale abbastanza resistente da creare piccole cavità all'interno del pezzo per resistere alle alte pressioni.

Soluzione

Ottimizzazione della geometria interna per prestazioni migliori

Grazie all'ottimizzazione delle geometrie interne del pezzo, la quantità di aria compressa necessaria per svolgere la sua funzione è stata ridotta da 5,5 bar a 4 bar, con conseguente riduzione del consumo d'aria e una macchina più sostenibile. I piccoli canali creati all'interno del pezzo per dirigere il flusso d'aria hanno ridotto significativamente l'impatto acustico della macchina. In precedenza, con la parte in tubo forato di base, il flusso d'aria non aveva una direzione precisa e il singolo tunnel risuonava del suono della pressione dell'aria.

Un design migliore a un prezzo competitivo

Durante il processo di progettazione additiva, Girbau è stata in grado di progettare un pezzo con geometrie complesse, parti funzionali integrate, leggero e compatto. La natura additiva della tecnologia di stampa 3D fa sì che la creazione di un pezzo complesso non comporti un prezzo più alto e, anzi, a volte può essere più economica, dato che viene utilizzato meno materiale. Grazie a queste possibilità di progettazione, Girbau è stata in grado di creare un pezzo in un'unica soluzione che fosse economicamente vantaggioso. Ciò non sarebbe stato possibile con i metodi di produzione tradizionali, poiché le possibilità di progettazione per la produzione tradizionale richiedono stampi costosi e grandi volumi di produzione per compensare i costi.

Sfruttare al meglio le funzioni integrate

La semplificazione del loro pezzo, che ora aveva funzioni integrate come i supporti che consentivano di fissare facilmente il pezzo a una cremagliera all'interno della piegatrice. Un modello più compatto che non sarebbe stato possibile trovare sul mercato o che sarebbe stato difficile da creare con i metodi di produzione tradizionali.

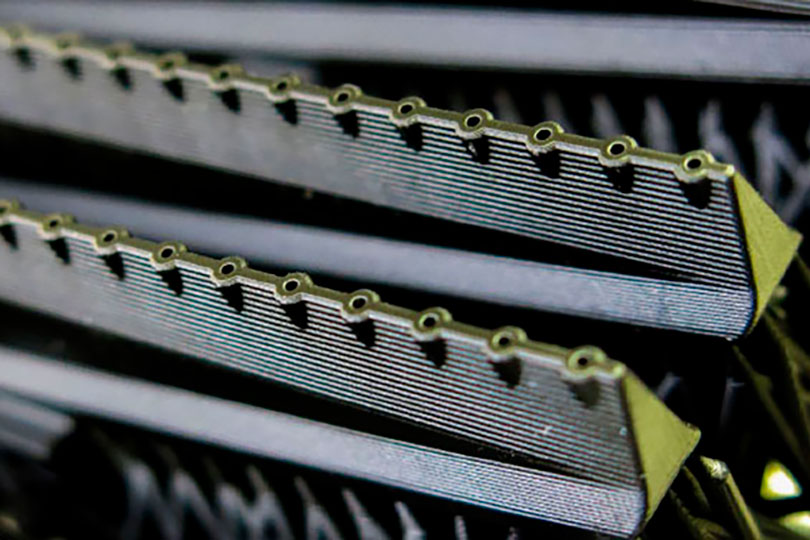

Ultracur3D® EPD 1006 & LC Magna : la precisione necessaria per affrontare le sfide della produzione

With a final design, Girbau turned to Sculpteo’s online printing service to create a prototype that would potentially be the final part for their machines. They decided on SLS (selective laser sintering) technology and Nylon PA12 material. When testing the part, they realised that there was excess powder from the PA12 material blocking the airflow. With Sculpteo’s responsive customer support, Girbau was advised to use LCD (Liquid Crystal Display) printing technology to create tiny channels within the part, which powder technology cannot do, using the resin material EPD 1006. Parts printed with resin materials have high accuracy and are perfect for designs that require high precision, like Girbau’s part.

Il negozio di stampa 3D risolve i problemi di riparazione del parabrezza con Photocentric LC Magna

The 3D Printing Store (3DPS) ha utilizzato Photocentric LC Magna per produrre una pinza di foratura personalizzata, rendendo la riparazione del parabrezza più facile ed efficiente che mai. Il partner di Photocentric 3DPS è stato contattato da Tim Evans e dalla sua azienda Crack Eraser - che aiuta altri imprenditori ad avviare le proprie attività di riparazione dei vetri auto - per sviluppare una parte per il suo sistema di kit di riparazione. La tecnologia proprietaria ha aiutato Crack Eraser a risolvere l'aspetto più difficile della riparazione dei parabrezza, ovvero la perforazione dello strato superiore del vetro stratificato del parabrezza nel punto di impatto in cui si è verificato il danno. Utilizzando Photocentric LC Magna , 3DPS è stata in grado di produrre oltre 1.000 pinze di foratura, entro tolleranze accettabili, in sole cinque ore di stampa.

Sfida

Il componente di precisione stampato in 3D serve a sostenere il minuscolo trapano per vetri utilizzato nella riparazione del parabrezza e ha reso questo processo critico di foratura rapido, affidabile e automatico. In passato, per apprendere la tecnica corretta era necessario un addestramento, molta pratica, un elevato grado di motricità fine e molto tempo per completare con successo una riparazione.

Soluzione

La nuova parte ha semplificato il lavoro e consente ai clienti di Crack Eraser di realizzare ogni volta il foro perfetto. Il negozio di stampa 3D ha dichiarato che la tecnologia Photocentric è stata essenziale sia nella fase di prototipazione rapida che in quella di produzione. Hanno potuto stampare più pinze di foratura per testare la profondità di appoggio della punta del trapano in ciascuna pinza e valutare se la riparazione del parabrezza era riuscita. Una volta finalizzato il progetto, la produzione è stata rapida e la post-elaborazione minima.

"È molto incoraggiante vedere un imprenditore innovativo come Tim che risolve le sfide utilizzando la tecnologia di produzione additiva con il nostro partner The 3D Printing Store", "Grazie all'ampio volume di costruzione, LC Magnaè una scelta eccellente per produrre parti di uso finale in modo rapido ed efficiente su scala, offrendo alle aziende velocità, volume e risparmi sui costi". La natura intricata di questo pezzo richiede strumenti di precisione e, in questo caso, LC Magna è stato in grado di fornire una soluzione agile e flessibile per la produzione".

Sally Tipping – New Business Development Director, Photocentric

Phone Skope si concentra su Photocentric LC Magna soluzione per risolvere la sfida della produzione

Phone Skope, leader nel settore del digiscoping, ha adottato una soluzione di produzione additiva su Photocentric per produrre i suoi adattatori per digiscoping stampati su misura. Il produttore statunitense produce adattatori di precisione per quasi tutti gli smartphone, consentendo alla fotocamera di uno smartphone di catturare immagini e video migliori attraverso un cannocchiale per applicazioni di birdwatching, fauna selvatica, microbiologia e astrologia. La soluzione di produzione additiva Photocentric - realizzata tramite il partner Merit3D, fornitore di servizi di produzione - comprende le stampanti Photocentric LC Magna e le unità di post-elaborazione, che consentono di modellare e creare gli adattatori in modo rapido, senza dover ricorrere a un costoso e lungo stampaggio.

A fast moving market – The Challenge

"La produzione di Phone Skope è stata sfidata dalla natura in rapida evoluzione del mercato, che richiede che i suoi prodotti siano compatibili con un numero enorme di nuovi modelli di telefono rilasciati ogni anno", dice Sally Tipping, Photocentric. "Al fine di creare un adattatore per digiscoping compatibile per un particolare modello di telefono, sarebbe stato necessario creare uno stampo per ogni nuova custodia, e c'era sempre la possibilità che il telefono stesso non fosse un successo commerciale. Questo significava che Phone Skope doveva scegliere tra quali modelli supportare e creare stampi per mantenere la redditività. La stampa 3D è stata un'eccellente soluzione a questo problema, dando a Phone Skope la flessibilità di portare sul mercato una maggiore varietà di adattatori a velocità senza le implicazioni di costo della creazione di stampi aggiuntivi. I prodotti Phone Skope sono rinomati in tutto il mondo per la loro precisione e durata, e quindi era anche fondamentale che queste caratteristiche fossero mantenute senza compromessi".

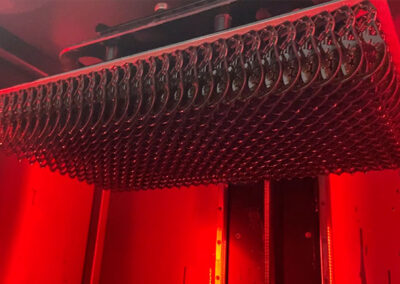

Photocentric e LC Magna - La soluzione perfetta

Per produrre le casse, Merit3D ha usato le sue stampanti 8 Photocentric LC Magna e le unità di post-processing Photocentric , le unità Air Wash L e Cure L2. Merit3D ha anche scelto la resina Daylight Magna Duramax di Photocentric. Il design di Phone Skope è un semplice sistema a due parti che è intercambiabile e funziona con la maggior parte delle combinazioni di smartphone e ottiche. Con solo un paio di piccole modifiche al modello 3D, una nuova custodia potrebbe essere progettata e stampata su larga scala con minime revisioni richieste utilizzando la produzione additiva. Questo ha ridotto i costi iniziali e aumentato il tempo di produzione in modo considerevole, con un output costante di alta qualità.

LC Magna si adatta a una vasta gamma di applicazioni di produzione, offrendo una velocità di stampa significativa, un volume di costruzione e vantaggi di costo. Merit 3D sapeva anche che le stampe di alta qualità prodotte da LC Magna avrebbero ridotto significativamente il tempo speso per la finitura finale, riducendo ulteriormente i costi e aumentando la velocità di commercializzazione.

Il software Studio diPhotocentrice 4D-additive sono stati utilizzati anche per incorporare i supporti necessari per la stampa nel design effettivo delle casse. A seconda delle dimensioni del prodotto finito, una singola piattaforma Magna poteva ospitare fino a 52 casse. Seguendo un semplice flusso di lavoro all'interno del suo stabilimento di produzione, il tempo di completamento per ciascuno degli ordini variava da 1 a 2 giorni. La nuova soluzione ha permesso di risparmiare migliaia di dollari in costi di attrezzature per la creazione di uno stampo, e anche i tempi per creare un nuovo modello di cassa sono stati ridotti da 1-2 mesi a sole due settimane. Grazie alla soluzione AM, anche un precedente ordine minimo di 2000 unità (per essere praticabile) è stato completamente eliminato.

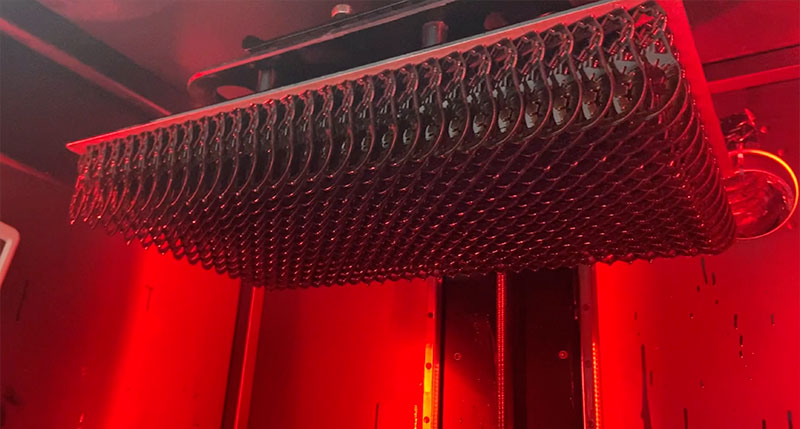

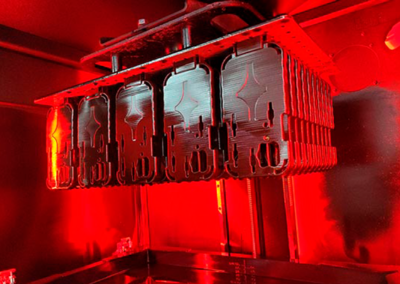

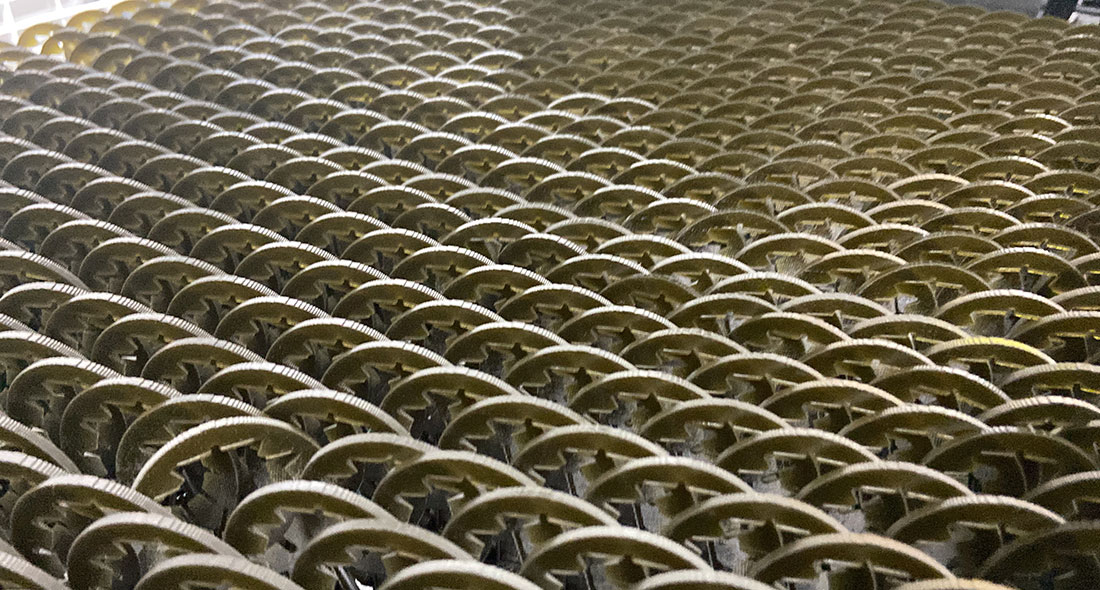

1,000,000 3D Printed Part Order For Adhesives Technology

Merit3D, azienda leader nella produzione additiva, sta producendo 1.000.000 di grucce per Adhesives Technology utilizzando la tecnologia di stampa 3D. Le grucce sono necessarie per ogni progetto di Adhesives, ma il processo di produzione è stato interrotto a causa dell'indisponibilità dello strumento di stampaggio a iniezione.

La soluzione di Merit3D ha aiutato Adhesives Technology a eliminare i costi aggiuntivi e i tempi di attesa per la consegna di un nuovo strumento e a riportare la produzione negli Stati Uniti.

The challenge – Access to injection mould tool

Adhesives Technology ha dovuto affrontare delle sfide a causa di eventi mondiali che hanno impedito l'accesso al proprio stampo a iniezione. L'utensile era necessario per produrre ganci per tenere insieme le cartucce epossidiche e gli ugelli di miscelazione. Il processo di produzione è stato interrotto e la costruzione di un altro stampo avrebbe richiesto troppo tempo, rendendo la stampa 3D l'unica opzione possibile. Tuttavia, la stampa 3D delle grucce avrebbe avuto costi proibitivi.

Solution – LC Magna

Merit3D ha offerto una soluzione alla sfida modificando il progetto di stampaggio e ottimizzandolo per la produzione additiva. In particolare, l'azienda ha ottimizzato il progetto per le stampanti Photocentric Liquid Crystal Magna. Il processo di riprogettazione iterativa di Merit3D è durato in tutto due settimane e ha portato a un progetto che poteva essere stampato in 3D in modo efficiente e conveniente.

Merit3D ha utilizzato 20 stampanti per produrre le grucce, con 400 grucce per piattaforma, impiegando 225 minuti per piattaforma. Il materiale utilizzato era Ultracur3D® EPD1006 di Photocentric e BASF ForwardAM, che ha fornito le proprietà ideali e ha superato il brutale test di durata.

Eliminating costly injection mould tool

La soluzione di produzione additiva di Merit3D ha permesso ad Adhesives Technology di continuare a lavorare con l'ordine di 1.000.000 di grucce, eliminando la necessità di un costoso strumento di stampaggio a iniezione. La soluzione dell'azienda ha inoltre consentito personalizzazioni e iterazioni multiple di progettazione per ottimizzare le grucce per il loro uso specifico. L'uso della tecnologia di produzione additiva ha inoltre ridotto gli scarti e l'impronta di carbonio.

PhotocentricLe stampanti Liquid Crystal Magna si sono rivelate ideali per la produzione in serie grazie al grande formato, all'elevata finitura superficiale, alla rapidità di produzione, alle resine funzionali ed economiche e al basso consumo energetico.

Il successo della produzione di Merit3D di 1.000.000 di grucce utilizzando la tecnologia di produzione additiva dimostra il potenziale di questa tecnologia per la produzione su larga scala. Ottimizzando il progetto per la stampa 3D e utilizzando le stampanti Photocentric Liquid Crystal Magna, l'azienda è riuscita a produrre le grucce in modo efficiente ed economico.