How to Streamline your Supply Chain

New strategies for streamlining supply chains are emerging as we combine Plastic Injection Moulding with Additive Manufacturing to meet demand. This is an illustration of how to make the most of both fabrication methods throughout a product life cycle.

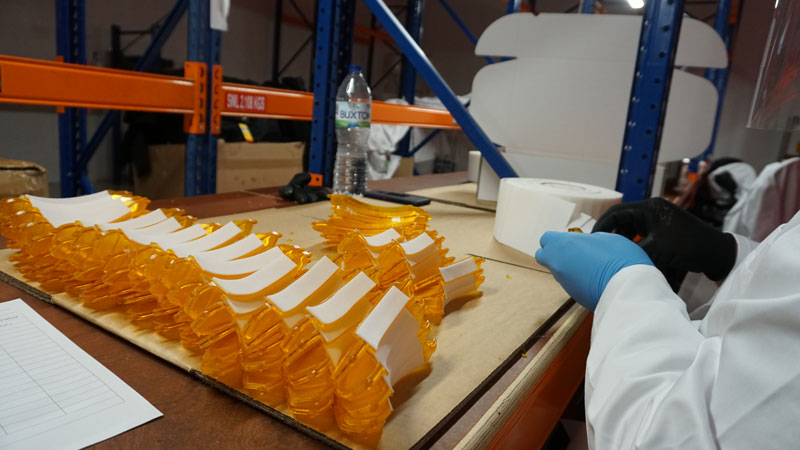

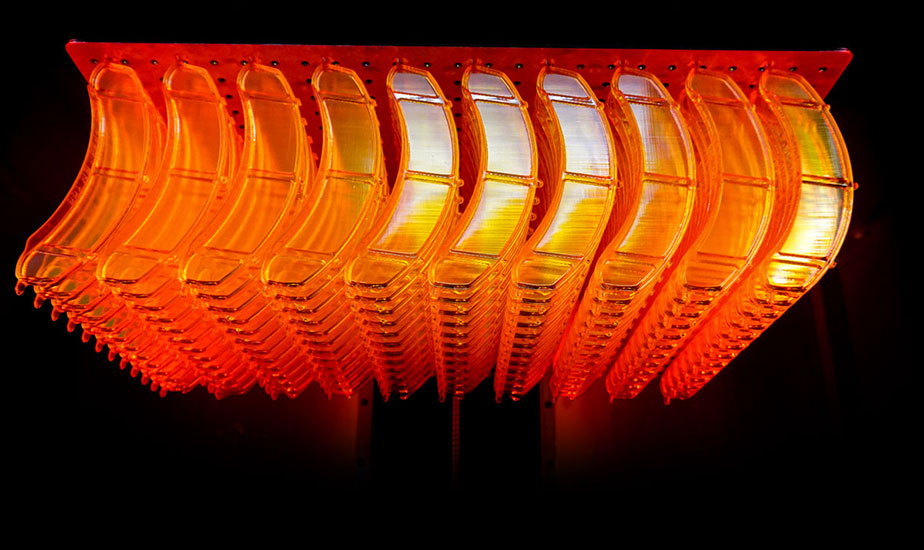

Photocentric scaled up the production of face shields to a million a month to meet an imperative demand for the shortage of PPE equipment on the face of the COVID pandemic using 3D printing technology.

What’s remarkable about this story is that it took less than two weeks for Photocentric to start manufacturing in large volume. In the first two months, we worked hard to create 200,000 parts with a lot of manual intervention, but in the following month we made 1 million face shields in a production environment. This was done thanks to a series of design and printing iterations to increase speed of manufacturing to provide adequate protection against the particular hazards for which they are designed according to Government standards.

Design iterations of the face shields separator chronologically from top left to bottom right

The freedom of design and the ability to go straight from prototyping to full production is one of the major advantages of additive manufacturing allowing us to quickly design items, use materials efficiently, manage production based on demand and control the lead times and quality of our supply chain. It helps keep the cost of tooling down, reduce shipping and warehousing and operate more sustainable processes as a result.

At the time we converted our 3D print farm into a mass production site, we also set out to establish a real-time comparison by creating the same part using Injection Moulding. This study enabled us to put data behind the two processes and to explore the difference in performance, time to market and cost between the two manufacturing technologies.

What was the time saving? To set up the Injection Moulding process took 156 days as opposed to 10 days with LCD-based 3D printing. Time was the most significant gain of the process enabling Photocentric to accelerate time-to-market to fulfil a critical need and protect the frontline workers during the pandemic.

The best of both worlds

The performance of both parts in the face shield was identical irrespective of the manufacturing process used. The break-even-point in number of parts for Injection Moulding compared to 3D printing was 320,000 units. However, setting up the process to enable that production took 156 days and during that time, the delivery of PPE equipment was fulfilled via Additive Manufacturing. This project demonstrated that 3D printing can be used effectively beyond prototyping to deliver mass manufacturing applications at scale and speed.

In industry, following the development phase, the typical product life cycle usually starts with a slow uptake during the initial growth period. These short runs can easily be supplied using 3D printing technology. If the commercialisation of the product is successful and sales take off, there may come a point in time when the demand for the product grows to a size so large that Injection Moulding becomes more cost-effective. After a certain time, on the decline phase of the product lifecycle, the demand is likely to reduce, or the product may be discontinued but spare parts may still be required. 3D printing again becomes the most efficient and economical production technique to fulfill such dwindling demand.

Combining both Injection Moulding and Additive Manufacturing brings a world of limitless possibilities. Photocentric’s most innovative customers plan and design with a view to using both production methods from the start of a project to secure a competitive advantage.

The agility that AM brings to product design coupled with how organisations use technology, opens up a world of possibilities in design, manufacturing and supply chain management.

Further reading

Xkelet and Photocentric’s innovative collaboration is transforming the way bone fractures are treated worldwide.

The powerful alliance of Xkelet and Photocentric has seen the creation of an advanced solution to traditional orthotics; one which is revolutionising the treatment of damaged bones. Tailored to Xkelet’s application and unique operation, the XKprinter was shaped.