On a mission to launch the first autonomous

3D printing manufacturing platform to space.

In the harsh and unforgiving environment of space, a significant challenge exists: how do we sustain life for longer periods without dependency on expensive maintenance missions to repair broken equipment and replace aging components? One of the highest costs of space missions is simply staying up there due to the constant need for essential maintenance and resupply.

On a mission to launch the first autonomous 3D printing manufacturing platform to space.

In the harsh and unforgiving environment of space, a significant challenge exists: how do we sustain life for longer periods without dependency on expensive maintenance missions to repair broken equipment and replace aging components? One of the highest costs of space missions is simply staying up there due to the constant need for essential maintenance and resupply.

In 2023, we embarked on the complex journey of developing a unique 3D printing solution for space manufacturing – one that, while well-proven on Earth, could operate in the extreme, zero-gravity environment of space. This vision was and is focused on delivering a robust solution to equip astronauts with a fully autonomous parts manufacturing platform for a new generation of orbital stations and spacecraft, which are currently in development as existing platforms such as the International Space Station (ISS), near retirement.

With vital funding from the European Space Agency (ESA) and in working partnership with Catapult Satellite Applications and Business in Space Growth Network (BSGN), we’ve made significant progress in turning this vision into reality through our development of CosmicMaker: a fully autonomous manufacturing platform for space applications.

CosmicMaker development rig in action printing in all orientations

Utilising unique patented designs and the well-proven LCD 3D printing technology that Photocentric pioneered in 2005, CosmicMaker has reached a substantial milestone in its development, to date proving it:

- Can print parts in any orientation.

- Perform robustly in a wide range of positive and negative g-force, and full vacuum environments, an early indication of zero gravity suitability.

- Is the lightest, most compact, most reliable, lowest-energy, and most productive 3D printer design for space applications.

- Can reliably print a wide range of functional materials, ideally suited to space applications, including:

- Thermosets: Elastomeric, high-temperature, ESD, high-impact, etc.

- Composites: Fiber-reinforced polymer, ceramic-filled, etc.

- Ceramics: Silicon carbide, alumina, etc.

- Metals: Stainless steel, titanium, etc.

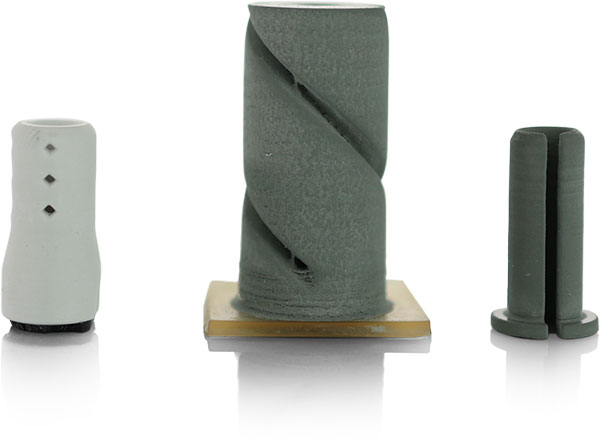

Printed samples from CosmicMaker

Left to right: Alumina, Silicon carbide x2

From lab to launchpad – the next phase of our programme.

Having successfully demonstrated CosmicMaker potential on Earth, we are now beginning the next crucial phase of our programme – proving its effectiveness in space.

This next phase of the programme will involve:

- Testing CosmicMaker in a parabolic flight to simulate and validate it’s capabilities in microgravity conditions.

- Advancing discussions and preparations to send CosmicMaker to the International Space Station (ISS) for in-space testing.

Discussions are actively underway on how to achieve these milestones and work towards establishing CosmicMaker as the first autonomous, on-demand manufacturing platform in orbit.

With significant progress already made to date, continued collaboration with industry and government partners will be crucial in unlocking the full potential of in-space production and ensuring the next generation of spacecraft and space stations are equipped with fully autonomous manufacturing capability.

The Photocentric CosmicMaker programme marks just the beginning of a really exciting journey, and we’re excited to be part of shaping the future of orbital space manufacturing. Further updates will follow as development progresses!

For further information, please visit our 3D Printing in Space page below.