VXL Technologies helps Railex increase functionality and efficiency of garment conveyor system

By integrating 3D printing into both prototyping and production stages, VXL Technologies was able to reduce development time, increase product reliability, and save on costs for Railex by using transfer connections made on LC Magna.

“We were able to reduce development and production time significantly, to meet deadlines”

Matthew Mendez

Owner, VXL Technology

VXL Technologies helps Railex increase functionality and efficiency of garment conveyor system

By integrating 3D printing into both prototyping and production stages, VXL Technologies was able to reduce development time, increase product reliability, and save on costs for Railex by using transfer connections made on LC Magna.

“We were able to reduce development and production time significantly, to meet deadlines”

Matthew Mendez

Owner, VXL Technology

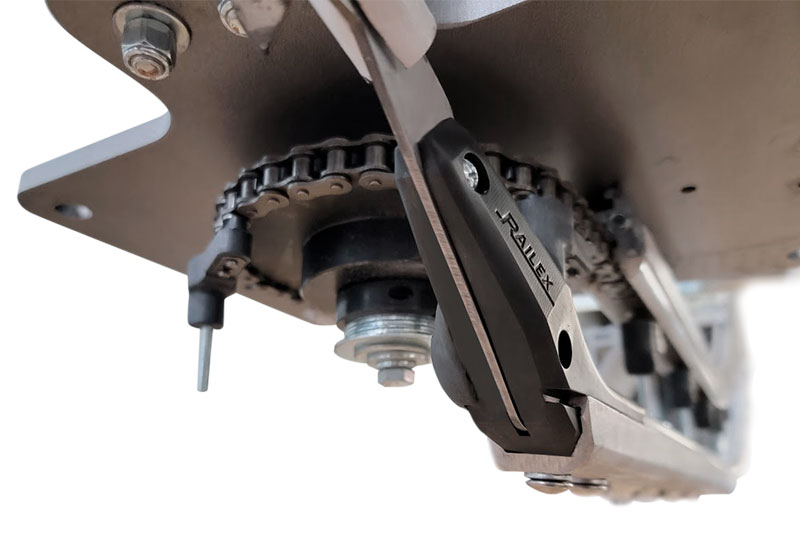

Transfer connections for conveyors

The conveyors designed for Railex are traditionally used for garment handling on hangers. The project involved developing an updated transfer conveyor system with VXL Technologies, leveraging 3D printed parts to connect and integrate seamlessly with other systems manufactured by various vendors.

The project culminated in a fully modular ramp system, which can be easily installed on linear sections of the track extrusion, enhancing the flexibility and functionality of the conveyor system.

Sfide

The garment industry requires conveyors to handle hangers that vary significantly in size, shape, weight, and stability. One of the critical challenges was designing transfer points that could manipulate hangers using only their hooks, ensuring smooth and reliable operation despite the variability in hanger shape.

Building the right hardware demanded materials that were not only wear-resistant but also ductile, maintaining specific shapes required for the application. Traditional UHMW Plastic, while machinable to the required geometries, posed limitations in terms of machining complexity and development costs.

The solution was to manufacture a specialized piece of hardware designed to fit within an aluminum extrusion system. This component acts as both a sacrificial wear material and the primary guide, facilitating the connection between slick rails and the conveyor system.

Customer Focused Questions

Why did you choose 3D printing for the specific problem or challenge?

Prototype – 3D printing was chosen for prototyping because it allows VXL Technologies to accelerate development cycles significantly. By using the same method for both prototyping and larger-scale production, the transition from development to manufacturing is streamlined, reducing overall time and costs.

Variable quantity needed – VXL’s resin printing capability can efficiently handle production runs ranging from test batches of single units to larger orders of thousands per week, depending on the part size. This printing flexibility is crucial for meeting customer development needs and having a short product lead time.

Bridge production – The conveyor industry often requires production-specific features. VXL’s use of the LC Magna printer enables high levels of manufacturing flexibility, allowing for rapid adjustments and iterations as needed.

Mass customization – 3D printing supports the mass customization necessary for VXL’s projects, enabling the production of tailored components that meet specific client requirements without the need for extensive retooling. – The conveyor industry often requires production-specific features. VXL’s use of the LC Magna printer enables high levels of manufacturing flexibility, allowing for rapid adjustments and iterations as needed.

Why did you partner with Photocentric?

Material options – BASF/Photocentric Resins outperform typical desktop machine resins, providing superior performance for our applications.

Project support – We received comprehensive support with resin and printer supplies, ensuring uninterrupted development and production.

No tooling needed – The lack of tooling requirements reduced setup times and costs, enhancing overall efficiency.

Other – Lights-out manufacturing capabilities enable the production of hundreds of parts, regardless of complexity, with minimal supervision.

Money saved – By utilizing 3D printing, we saved an average of a week’s worth of engineering and fabrication time, significantly reducing project timelines.

Parts – Resin printing allowed us to develop parts without disrupting our regular production schedules, maintaining continuous workflow.- By utilizing 3D printing, we saved an average of a week’s worth of engineering and fabrication time, significantly reducing project timelines.

Time and CO2 reduction – Previous experience with Photocentric’s machines and resins made it an easy decision to choose them for scalable additive manufacturing. Their larger format machines work well in handling production, resulting in more products per print, reducing waste and saving handling time

Ready to unlock breakthroughs in your manufacturing process?