3D printing solutions

Automotive Aftermarket

We supply resins that create printed parts that look and perform like tooled plastic. The cost-effective alternative, proven in real-life applications, used in all weather conditions.

Titan creates large dimensionally accurate pieces for numerous auto applications, such as panels and covers.

Magna is proven as the most effective method of making small and medium sized fixtures for the automotive aftermarket sector. It has created hundreds of thousands of parts for companies typically where they have a lot of designs with low to medium volumes that don’t merit tooling.

For large volumes of functional parts, there is only one solution, Magna.

3D printing solutions

Automotive Aftermarket

Magna is proven as the most effective method of making small and medium sized fixtures for the automotive aftermarket sector. It has created hundreds of thousands of parts for companies typically where they have a lot of designs with low to medium volumes that don’t merit tooling.

We supply resins that create printed parts that look and perform like tooled plastic. The cost-effective alternative, proven in real-life applications, used in all weather conditions.

Titan creates large dimensionally accurate pieces for numerous auto applications, such as panels and covers.

For large volumes of functional parts, there is only one solution, Magna.

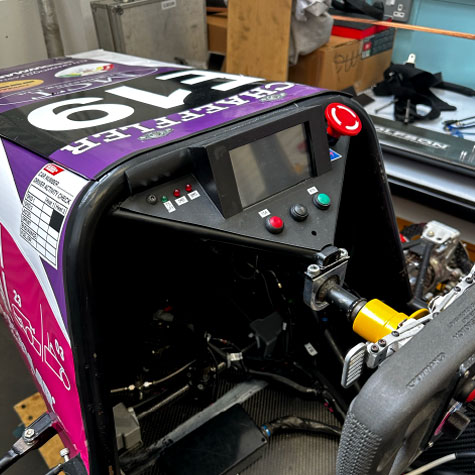

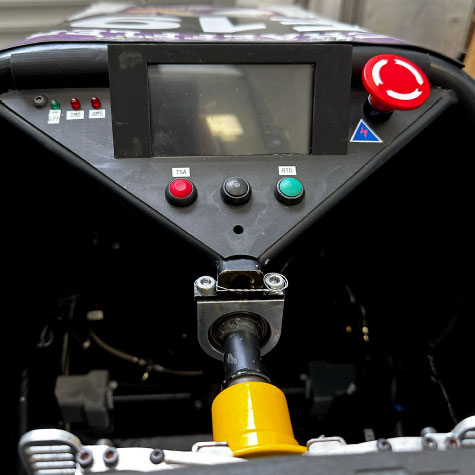

LUMotorsport

Since 2003, LUMotorsport has represented Loughborough University at Formula Student events worldwide. The primary event is Formula Student UK, held at Silverstone each year. Last year 60 + teams from the UK and around the world competed. The team has also competed in Austria, Czechia, Germany and Hungary.

In 2023, LUMotorsport approached Photocentric to utilise their expertise in 3D printing. Working together, they have printed multiple aerodynamic parts, composite tooling and motorsport-standard electrical junction boxes for this year’s car, using the Liquid Crystal Magna 3D printer offering the following:

- Large-scale parts

- Complex, non-planar geometry

- Large height to bed contact area ratio

- Clean surface finish to minimise skin friction

- Increased design freedom for carbon tooling without the constraints of machining tooling block

- Lower weight inserts for aerodynamic surfaces compared to previous aluminium ones

LUMotorsport

Since 2003, LUMotorsport has represented Loughborough University at Formula Student events worldwide. The primary event is Formula Student UK, held at Silverstone each year. Last year 60 + teams from the UK and around the world competed. The team has also competed in Austria, Czechia, Germany and Hungary.

In 2023, LUMotorsport approached Photocentric to utilise their expertise in 3D printing. Working together, they have printed multiple aerodynamic parts, composite tooling and motorsport-standard electrical junction boxes for this year’s car, using the Liquid Crystal Magna 3D printer offering the following:

- Large-scale parts

- Complex, non-planar geometry

- Large height to bed contact area ratio

- Clean surface finish to minimise skin friction

- Increased design freedom for carbon tooling without the constraints of machining tooling block

- Lower weight inserts for aerodynamic surfaces compared to previous aluminium ones

Panneau pour caravane Hymer

Impression de pièces prototypes à grande échelle

Le VisionVenture, créé conjointement par BASF et HYMER, est un aperçu proche de la production de l'avenir des fourgonnettes. Les panneaux de carrosserie du prototype ont été imprimés à l'aide de l'imprimante Titan Liquid Crystal .

Panneau pour caravane Hymer

Impression de pièces prototypes à grande échelle

Le VisionVenture, créé conjointement par BASF et HYMER, est un aperçu proche de la production de l'avenir des fourgonnettes. Les panneaux de carrosserie du prototype ont été imprimés à l'aide de l'imprimante Titan Liquid Crystal .

Hymer Panel

Détails d'impression :

Imprimante : Liquid Crystal Titan

Dimensions : 920 (L) x 470 (H) x 600mm (L)

Temps d'impression : 40 heures

Résolution : 100µm

Volume de résine : 800g

Résine : Noir dur lumière du jour

Coût unitaire : 48,96 euros