Cast DL60 3D Resin

$506.00 excl vat

FREE UK shipping on orders over £250

Cast DL60 is an affordable, high-performance, antimony-free castable resin designed to deliver clean and reliable investment casting results. It has been engineered to exhibit waxlike behaviour at elevated temperatures without the use of wax additives, eliminating the dimensional instability and difficult processing conditions often associated with wax-filled resins. With its excellent printability, low viscosity, and high accuracy, it is simple to process on LC Magna and LC Titan. The result is a resin that produces stable, precise patterns and consistent casting performance from initial print to final cast part.

5Kg

Best Used for:

Suitable for both shell casting and flask casting

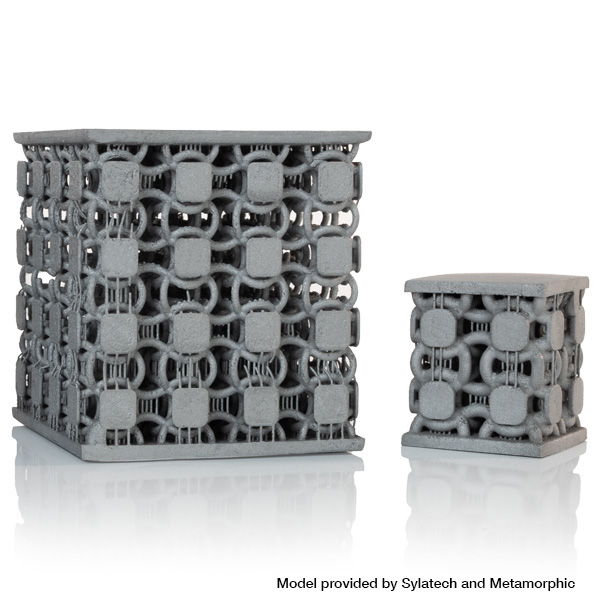

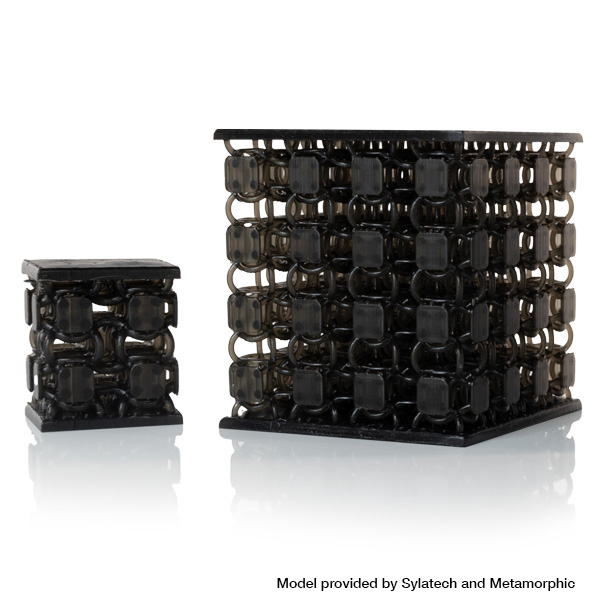

• Shell casting – For medium to large, complex patterns without the need for tooling

• Flask casting – For small to medium, complex patterns, including latticed geometries

• Casting of all common metals – Broad compatibility enabled by its low burnout temperature

Features:

• Wax-free formulation – better dimensional stability and processing.

• Clean burnout – ultra-low ash content ensuring contamination free castings.

• Antimony-free – No trace metals

• Low thermal expansion – minimising risk of shell cracking during burnout.

• Low viscosity – enabling easier processing, printing and fast drainage.

• High green strength – self supporting parts that retain dimensional stability.

• Moisture and humidity resistance – consistent results in demanding environments.

LC Magna and LC Titan

2200 MPa

40 MPa

40%

1880 MPa

76 MPa

50 J/m

Coefficient of Linear Thermal Expansion (20°C – 120°C) *

Coefficient of Linear Thermal Expansion (120°C – 200°C)*

Ash Residue*

Antimony content

Water Absorption 24 hrs

Water Absorption 48 hrs

Water Absorption 7 days

85 Shore D

61°C

66μm/m/°C

–

180μm/m/°C

–

0.1%

0%

0.22%

0.24%

0.43%

630 cPs

1.06g/cm3

0<T<50°C

Black

Internal

–

Internal

–

Internal

–

Internal

Internal

Internal

At 25°C Brookfield spindle 3

Internal

–

*Post cured for 5 hrs at 40°C in Photocentric Cure L2/Cure XL.

2200 MPa

40 MPa

40%

1880 MPa

76 MPa

50 J/m

85 Shore D

HDT (@ 0.455 MPa)

61°C

ASTM D648

Coefficient of Linear Thermal Expansion (20°C – 120°C)

66μm/m/°C

Coefficient of Linear Thermal Expansion (120°C – 200°C)

180μm/m/°C

Ash Residue

0.1%

Antimony content

0.1%

Water Absorption after 24 hrs

0.22%

Water Absorption after 48 hrs

0.24%

Water Absorption after 7 days

0.43%

1.06 g/cm3

Black

*Post cured for 5 hrs at 40°C in Photocentric Cure L2/Cure XL.

Reviews