Photocentric react to Covid-19 outbreak with the mass manufacture of thousands of PPE parts a day for front line healthcare workers

Peterborough based innovator and specialist 3d printer manufacturer, Photocentric, have changed their business since the outbreak of Covid-19. To help hospitals and other health providers with the current shortage in PPE, Photocentric are using their large-format machines to print thousands of protective face shield parts a day

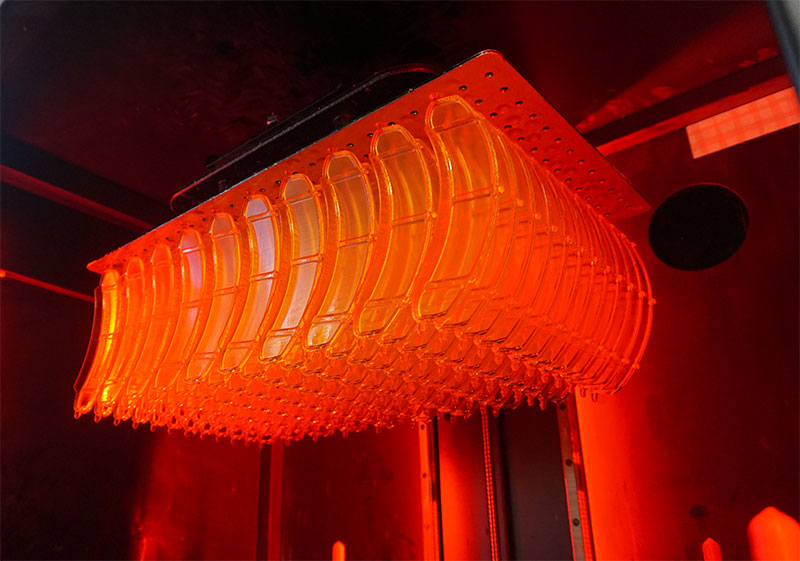

3D Printing Farm Mass Manufacture Thousands of Shields a Day

After seeing the story of a ventilator valve 3D printed for an Italian hospital, Photocentric began to think about how they could help support hospitals using their large-format printer farm which can produce vast numbers of parts per day.

Receiving a large and immediate demand from hospitals both local and further afield for protective face shields, Photocentric reacted quickly; designing, printing and testing a 3D printed shield part in a day. A day later, the design had been approved by doctors both locally and in Spain.Usually used for test parts for customers and to trial new resins, Photocentric’s fleet of LC Magna large-format printers were turned over for immediate use. Each printer produces 135 shield parts every hour with Photocentric’s optimised technology. OPRO, the very successful, innovative, double Queen’s Award manufacturer of mouthguards loaned Photocentric their 5 LC Magna printers to help increase the daily print capacity and deliver to those in need. With the help of their suppliers and customers, Photocentric are now delivering tens of thousands of shield parts a day for the NHS and healthcare heroes working on the front line during COVID 19.

Founder Paul Holt says: “We have lots of LC Magna and LC Maximus printers on site and are turning them all over to making parts for face shields.

We will produce thousands of them a day and enable others to do so as well.”Since the outbreak Photocentric have changed their business. They have enabled the manufacture of goods locally and at a speed and scale impossible with traditional manufacture or other conventional 3D printing technologies.