Welcoming Innovators into the In-orbit Manufacturing Accelerator

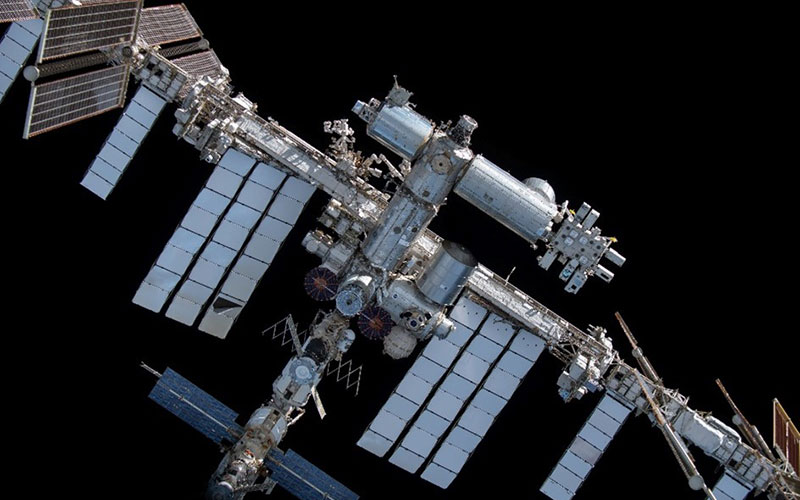

Credit NASA

Photocentric, pioneers of LCD 3D printing, have chosen Formnext to launch the world’s largest LCD printer, Liquid Crystal Titan.

The Business in Space Growth Network (BSGN) In-orbit Manufacturing Accelerator (IMA), led by Satellite Applications Catapult, proudly welcomes two distinguished innovators, Photocentric Limited and Deployables Cubed GmbH (DCUBED), into the top tier of the Accelerator. Both companies will apply materials and manufacturing expertise towards advancing transformative solutions for the development and autonomy of new in-orbit infrastructures.

The European Space Agency, via the BSGN programme facilitates pathways for active engagement and involvement of private industries to adapt their capabilities and drive innovation towards commercialisation in the Lower Earth Orbit (LEO) economy. The initiative builds on the ESA’s objectives to accelerate the development of new in-orbit infrastructures and services.

Through an intensive 12-month programme, the IMA will collaborate with both companies using its multidisciplinary expertise and enabling ecosystem, helping to de-risk technology development. The IMA paves the way for in-orbit demonstration and commercialisation of new innovations.

The inclusion of both Photocentric and DCUBED mark a significant step forward in the Accelerator’s mission to advance in-orbit manufacturing capabilities and reinforce the collective strength of the European space industry. In addition to assisting technology development and commercialisation, we will work to strategically position innovators in the fast-evolving supply chain of this emerging segment filled with challenges and great opportunities.

Credit ESA

New solutions from Photocentric and DCUBED

Photocentric, a reputable UK-based additive manufacturing innovator, will embark on the development of CosmicMaker – a patented LCD-based 3D printer designed for upcoming space stations and orbital terminals. The technology is capable of additively manufacturing intricate near-net shape functional parts from Silicon Carbide, representing major advancements over existing in-space manufacturing solutions.

Paul Holt, CEO, Photocentric Group, remarked: “By leveraging Silicon Carbide, we are enabling the on-demand production of a significantly broader range of vital space-grade tools, parts and components onboard space stations. CosmicMaker is designed to address the need for substantially greater resource effectiveness, operational efficiency and autonomy of in-orbit infrastructures.”

He added, “Our collaboration with the European Space Agency IMA allows us to navigate new opportunities the space sector offers for transferring our precision manufacturing know-how and adapting our innovations to an exciting new range of in-orbit applications.”

DCUBED, a German NewSpace scale-up focusing on release mechanisms, solar arrays and other deployable mechanisms, will concentrate on maturing the technology readiness level of its robotic extrusion system aimed at aiding the manufacture of large structures in the vacuum of space.

The inclusion of both Photocentric and DCUBED mark a significant step forward in the Accelerator’s mission to advance in-orbit manufacturing capabilities and reinforce the collective strength of the European space industry. In addition to assisting technology development and commercialisation, we will work to strategically position innovators in the fast-evolving supply chain of this emerging segment filled with challenges and great opportunities.

Credit NASA

A Commitment to Innovation and Collaboration

Established in February 2022, the In-orbit Manufacturing Accelerator (formerly called Advanced Materials and Manufacturing Accelerator) is a Europe-wide multidisciplinary acceleration programme. This Accelerator generates and co-invests in novel engineering solutions for in-orbit manufacturing and infrastructure development, as well as advanced materials innovations that leverage microgravity R&D platforms.

Operating at the intersection of the Space, Advanced Materials and Manufacturing sectors, we both leverage and facilitate cross-sector collaboration, driving development of cutting-edge engineering solutions. This closely aligns with our mission of advancing European capabilities to accelerate the development of a sustainable marketplace for commercial microgravity R&D and state-of-the-art in-orbit infrastructure.

The Accelerator is an initiative sponsored by the European Space Agency’s BSGN Industry Accelerator programme and funded by the European Space Agency. Bernhard Hufenbach, Lead, Commercialisation and Innovation Team at ESA’s Human and Robotic Exploration department, expressed ESA’s dedication to the programme, stating:

ESA is committed to participating in the development of a market-driven economy in low Earth orbit. The BSGN accelerators, including the In Space Manufacturing Accelerator, are deployed to strengthen the competitiveness of European industry, stimulate research and development, and integrate innovative solutions into ESA space exploration missions.

Funded by ESA