A new dedicated range of Engineering Plastic Daylight 3D printing materials released from dynamic Forward AM and Photocentric relationship

- Photocentric and Forward AM by BASF take further strides to enable the custom mass manufacture of 3D printed parts

- Extended range of the tailor-made high-performance materials introduced to the market, including three photopolymer resins and one resin cleaner

- New performance materials to join two previously launched ‘Ultracur3D® Powered by Photocentric’ photopolymer products

- Offering expands new opportunities to propel further industrialization of Additive Manufacturing to manufacture mass-scale items at competitive costs

Working with Forward AM by BASF, Photocentric are continuing to provide solutions to overcome the previous limitations of Additive Manufacturing for mass manufacture, with the release of four new high-performance materials to enable a wide range of versatile 3D applications at competitive cost.

Since 2018, UK-based photopolymer resin and LCD printer manufacturer, Photocentric have worked with BASF, one of the largest chemical producers in the world, to create the much-needed photopolymer solution to enable the 3D custom mass manufacture of parts.

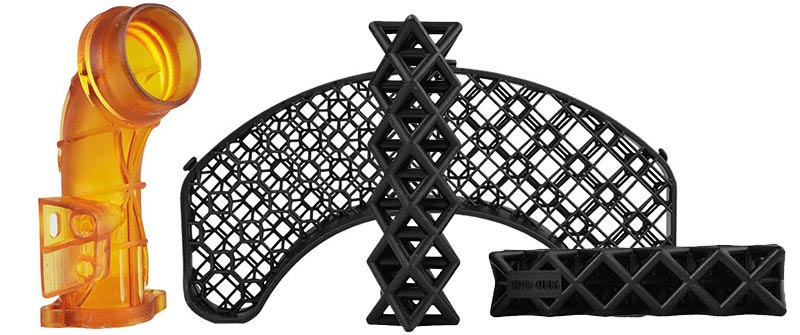

The latest Engineering Plastic Daylight (EPD) photopolymer products to join the range, include three new resins and one cleaning solution for resin-printed parts. Ultracur3D® EPD 1086, EPD 3500 and EPD 4006 will immediately join the previously released Ultracur3D® EPD 1006 and Ultracur3D® EPD 2006 that launched in late 2020.

These next-level high performance materials will add further versality and options for professional manufacturers using additive manufacturing and cover an even wider range of applications, to support industrial innovators, leveraging large scale and high productivity of Photocentric’s printers.

Ultracur3D® EPD 1086 provides businesses with a cost-effective solution for a wide range of applications. With exceptional hardness, the multi-purpose daylight resin achieves great printed functional parts results and promises to offer a lowest cost per part than other comparable materials.

Ultracur3D® EPD 3500 is a strong daylight amber resin with superior strength and stiffness, ideal for engineering prototypes and high-quality parts when translucency is required.

Ultracur3D® EPD 4006 is a durable daylight resin with exceptional toughness and impact resistance. As the parts produced are easy to print and have a fabulously smooth surface finish, it is ideal for functional parts and top-level multi-industrial applications.

In addiiton to the three new resins, the release sees Ultracur3D® Cleaner join the range, to add superior cleaning capabilities to the line up. The quick and efficient solution is compatible with a wide variety of resins, incl. most resins of the Ultracur3D portfolio and is ideal for removing any uncured photopolymer resin from printed parts and leaves no white mark residue.

“The recent releases show our continued commitment to enabling manufacturers to move forward with mass parts production through AM. The combination of these additional high-performance materials, with our Photocentric printers opens up even more opportunities for our customers.” Sally Tipping, Sales Director, Photocentric Ltd commented.

“This further expansion of our joint resin portfolio will enable us to offer our customers the best material solutions fitted for their needs. Enlarging of the portfolio is the natural next step of our collaboration. It’s manifesting our continued commitment on working together to develop the functional photopolymers of the future, delivering the best-in-class properties necessary to make cost-effective end-use parts on an industrial mass production scale a reality today”, says Dr. Piotr Bazula, Global Key Account and Business Development Manager Line Liquid Formulations & Systems, BASF 3D Printing Solutions.