1/10th of the cost and 50 times faster

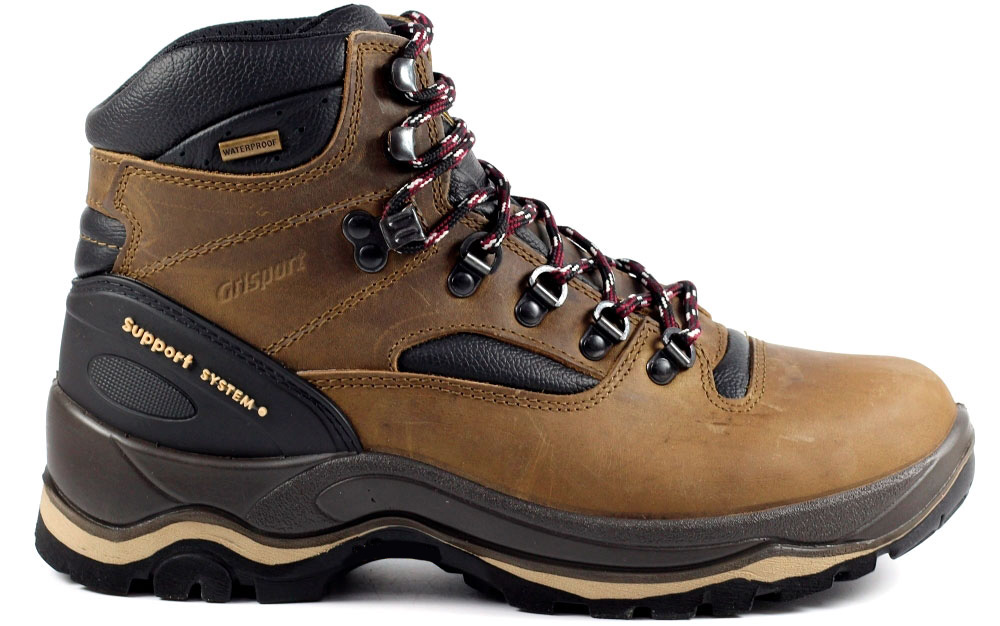

Grisport is an innovative Italian shoe manufacturer who wanted to improve their margins and go to market quicker by printing their tooling, this is their amazing story.

Grisport

Founded in 1977, Grisport is one of the leading companies in direct injection and shoemaking worldwide. They chose the Liquid Crystal Magna because it is one of the largest printers of its kind, it’s cost effective and very fast.

“3D printing with Magna with the help of QI factory is going to change fundamentally the way we bring moulds and products to the market.”

Giovanni Grigolato

Head of R&D at Grisport

Capacity

510 x 280 x 350 mm

(20.1 x 11 x 13.8”)

Print full sized shoe moulds

Speed

up to 86mm per hour

(3.4” per hour)

Functional moulds, fast

The special properties of HighTemp DL401 resin

HighTemp DL401 is specially made for printing tooling, giving you remarkable high temperature resistance and the highest accuracy in large parts, hardness under compression and enough elongation to mate and seal, characteristics necessary to enable the injection of molten plastic.

Magna and HighTemp DL401 are transforming the way shoe moulds are being made. You can now use the same plastics and the same process as an aluminium mould, but with all the advantages of lower cost and faster to market

“HighTemp DL401 is very good for us because it reaches the higher temperatures necessary for PU injection and keeps them stable.”

Giovanni Grigolato

Head of R&D at Grisport

LC Magna & DL401 distributed by QI Factory

Photocentric’s Italian Distributor