3D Printing for Manufacturing

Manufacturers are under pressure: fragile supply chains, rising costs, and the need to innovate faster. 3D printing can offer a smarter way forward.

Why Manufacturers Are Turning to 3D Printing

3D printing is no longer just for prototypes. It’s transforming how products are designed, optimised, built, and delivered, across the entire lifecycle.

Faster Prototyping & Production

Lower Costs for Short Runs & Custom Parts

On-Demand Manufacturing with

Less Inventory Risk

Greater Design Freedom

Local Production – Shorter Lead Times

& Lower Emissions

Functional Materials – Enhance Final Parts

How Photocentric 3D Printing Powers Modern Manufacturing

Product Development and Prototyping

Faster decisions, better products, and shorter time-to-market.

Speed matters. 3D printing lets you go from CAD to physical part in hours, not weeks.

- Accelerate iteration: Test multiple design versions quickly.

- Cut costs: Eliminate tooling and outsourcing expenses.

- Improve collaboration: Share real, functional prototypes with stakeholders early.

Tooling and Moulds

Agile production lines and lower tooling investment. Traditional tooling is slow and expensive, especially for short runs or evolving designs.

- Rapidly produce custom tools: Jigs, fixtures, moulds, and gauges.

- Adapt on the fly: Update designs without retooling.

- Reduce downtime: Manufacture tools in-house, on-demand.

End-Use & Custom Parts

Leaner operations and more responsive production 3D printing isn’t just for prototypes anymore.

- Produce complex geometries that traditional methods can’t handle.

- Enable mass customisation: Tailor parts to individual needs without added cost.

- Print only what you need: Reduce inventory, waste, and storage costs.

- Functional Materials: Produce final parts rather than prototypes with a large selection of materials.

Scalable Manufacturing

True digital manufacturing – fast, flexible, and scalable.

Forget the old limitations – 3D printing is now ready for the Industry 4.0 factory floor.

- JENI: Our fully autonomous mass production system combines robotics, additive manufacturing, and post-processing to provide the speed of injection moulding, with the flexibility of 3D printing.

- Lights-out manufacturing: Run 24/7 with minimal human intervention.

- Industrial scale: Produce thousands of parts with consistent quality.

Download our Free Buyer’s Guide

Ready to explore how 3D printing can transform your manufacturing?

Our takeaway guide walks you through the key applications, benefits, and considerations for deploying additive manufacturing in a modern production environment.

What’s included?

- A breakdown of where 3D printing delivers the most value.

- Why 3D Printing is more than a printer.

- A readiness checklist to assess your fit.

See it in Action

Explore our Manufacturing Solutions

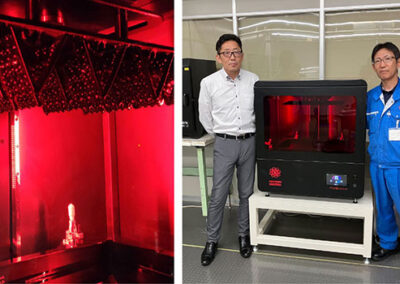

Photocentric LCD 3D Printers offer scalable, high-quality prototyping and production capabilities for a wide range of manufacturing industries, with cutting-edge resolution and production efficiency.

Autonomous Digital Mass Manufacturing

JENI combines robotics, additive manufacturing, and post-processing into a fully automated, lights-out production system, ideal for high-volume output.

High-resolution, Large-Scale Output

Precision meets scale. LC Titan delivers exceptional detail and speed for industries demanding high-quality, cost-effective production.

Large-Format LCD 3D Printer for Industrial Prototyping and Production

Built for professionals who need scale, speed, and reliability. LC Magna offers a large build volume, seamless workflow integration, and proven industrial performance.

Materials for Manufacturing

We offer a wide range of high-performance resins, engineered for demanding industrial applications. Our portfolio includes materials that are:

Durable

For long-term use

Flexible

For dynamic applications

High Temperature Resistant

For extreme enviroments

UV and Weather-Resistant

For outdoor and functional use

All materials are formulated and produced in-house, ensuring consistent quality and optimal performance. Whether you’re building functional parts or need materials that withstand UV ageing, our resins are designed to go beyond prototyping.

Customer case studies

From accelerating product development to enabling full-scale production, manufacturers across industries are adopting Photocentric’s LCD 3D printing solutions to solve real-world challenges:

VXL Technologies helps Railex increase functionality and efficiency of garment conveyor system

Wurtec’s Additive Manufacturing Breakthroughs with LC Magna

Photocentric solutions have opened up new possibilities and markets New Era

Printing large complex automotive panels for Magna International

Grisport is an innovative Italian shoe manufacturer who wanted to improve their margins and go to market quicker