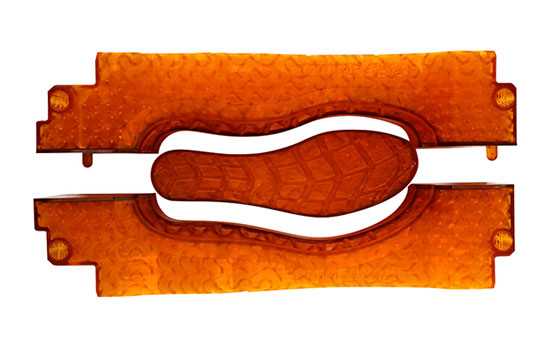

HighTemp DL401 resin – designed for printing injection moulding tooling

Shoe mould printed in HighTemp DL401 by Grisport an Italian shoe manufacturer

HighTemp DL401 is a remarkable new photopolymer from Photocentric. Years of development from our chemistry team, in collaboration with renowned beta users, have created our first genuine alternative to metal tooling.

HighTemp DL401 has extremely high temperature resistance, exhibits very high accuracy even in large parts, gives optimal strength and elongation under compression and enables parts to both mate and seal. It delivers the necessary characteristics for rapid and repeatable injection moulding.

You can see here how Grisport, one of Italy’s most innovative shoe manufacturers, used HighTemp DL401 in Liquid Crystal Magna to print moulds and with it transform their production.

Magna’s large build volume and Photocentric’s lattice software were key enablers in making this happen. Grisport injected the same plastics as they used in an aluminium mould, but at 1/10th of the cost and up to 50 times faster to market.

HighTemp DL401 is ideal for plastic injection moulding and tailored to be compatible with plastic injection moulding processes and plastics. It simulates the strength and stiffness of glass-filled Nylon 6 and enables the seamless transition from traditional manufacturing to 3D printing.

Key Features:

- Exceptional Performance- long-lasting under high temperatures and pressures

- Rapid Production- Print in 350μm layers, and accelerate the design process

- Smooth Finish- Excellent aesthetics with minimal post processing

- Minimal Shrinkage- dimensionally accurate parts

- Dry surface- contact face suitable for plastic part removal