Clear Stamps

Stamps Guaranteed to Make the Right Impression!

Our photopolymer clear stamps offer a high level of crisp, fine detail, durability, and consistency.

Clear Stamps

Stamps Guaranteed to Make the Right Impression!

Our photopolymer clear stamps offer a high level of crisp, fine detail, durability, and consistency.

Key Features

Tear Resistant

Tough, can be stretched and return to their original shape.

Naturally Sticky

Easy peel, easy attach, permanent stickiness to an acrylic block.

Long Lasting

Tens of millions made. Decades of experience. Long lasting impressions.

Deep Etch

Optimal 3.2mm (0.125″) thickness and deepest etch with finest detail.

Cost Effectiveness

Our scale and automation deliver value.

Low to High Quantites

Order from low quantities to 1,000´s of sheets.

Samples also available.

Crystal Clear

High clarity, shiny stamps that resist yellowing.

Low Carbon

Lowest carbon method of manufacture, we reuse 99% of polymer.

Fast Production

Typically, 10 days for orders & 4 days for samples.

Ink Compatible

Excellent performance with all water-based inks.

Sizes & Packaging

Your clear stamp sets are available in a wide range of UK and US sizes to suit your creative needs. Each set is carefully packaged with:

Clear Protective Acetate Backing Sheet

Printed Top Acetate Sheet

To showcase your designs

Custom Backing “insert” Card

Printed in high resolution on cardstock

Clear Bag with a Hanging Slot

Our Manufacturing

State-of-the-art stamp manufacturing facilities in the UK and US with automated stamp production lines, no other ones exist in the world, deliver optimal stamp performance.

All stamps are hand inspected and hand-packed with our personal touch.

Unique Ordering Portal

We have developed our portal over many years, and we are proud of it. We will help you create your online account. You upload designs and can see your entire artwork library in one location, just click on an image and order it.

Secure ordering system

- Upload, view and manage your artwork

- Create categories and organise files the way you want

- Customise packing specifications

- Place orders from your library

- View production lead times

- Request production slots

- View and track order status

- View your prices

- Request new specifications

Get Started in 5 Simple Steps

Unique Ordering Portal

We have developed our portal over many years, and we are proud of it. We will help you create your online account. You upload designs and can see your entire artwork library in one location, just click on an image and order it.

Secure ordering system

- Upload, view and manage your artwork

- Create categories and organise files the way you want

- Customise packing specifications

- Place orders from your library

- View production lead times

- Request production slots

- View and track order status

- View your prices

- Request new specifications

-

Get Started in 5 Simple Steps

Submit Your Enquiry

Create Your Account

Upload Your Artwork

Place Your Order

Recieve Your Clear Stamps

Contact Us

Take your first step today and a member of our team will provide you with the information you need.

Customer Testimonials

“We have confidence in the products that we get from Photocentric, because we know that they are top quality, and the quality does not change between batches. What we really like is their customer service, they were there with us every step of the way and they have supported us throughout. Having someone we can talk to directly has led to a very good working relationship with Photocentric. ”

“After a great deal of research and collating reviews, I knew that Photocentric would make the perfect manufacturer to partner with. Not only is the quality unquestionable, but nothing is too much trouble when you need help and advice… In 16 months my business has grown considerably, something that would not have been possible without my partnership with Photocentric”

“From the beginning, their commitment to delivering the highest quality has been a key reason we chose, and continue, to work with them. Their quick turnaround times and a team that’s always ready to help made them stand out early on, and that level of service has never wavered. But just as important as the products is the team behind them. The support we receive is outstanding – knowledgeable, approachable, and always available when we need them.”

“You offer the highest quality stamps, far superior to any others I have used. You definitely get what you pay for and I would never go down the cheaper route as the difference in the quality of the product is worth every penny and it reflects the ethos of my brand too, which is so important… All your team at Photocentric are so friendly, helpful and always quick to respond to any communications.”

Related Resources

How we guarantee dimensional accuracy in your clear stamps

How to Create Clear Stamps

“I have been in the craft industry for almost 30 years, but only designing product for the past 9 years.

I never envisaged designing my own products years ago mainly due to my lack of digital experience; I always had a preconceived idea that it was all too complicated.

Just over 16 months ago I decided to design products under my own branding rather than under another companies umbrella, I felt this would give me a little more design freedom. However, the digital/technology side I found quite daunting.

I already had designs planned but had no idea where to start. I have had my own businesses in different areas so understood that quality was key going forward and that a manufacturer with well known industry standards and knowledge was so important. After a great deal of research and collating reviews, I knew that Photocentric would make the perfect manufacturer to partner with. Not only is the quality unquestionable, but nothing is too much trouble when you need help and advice.

I do have to mention Neil, who is often there via email to help me in any way; either to simplify methods, help when I am struggling a little with technology and always eager to ensure I am happy with the finished product. This may not seem a big deal, however, when you are trying to get your business off the ground, I found the support during the process and after manufacturing a key factor as to why I return over and over to have my designs manufactured by Photocentric.

Quality and Customer Service are key in my own business and something I value very highly. These are also key attributes when building a working partnership with any manufacturer and Photocentric meet this criteria and more

In 16 months my business has grown considerably, something that would not have been possible without my partnership with Photocentric and Lisa.

It’s also important to me that my own designs are manufactured in the UK, supporting a UK based business. It’s also important to me to be part of a business relationship where all parties have the same business ethos and again, for me Photocentric is the perfect business model and fit for Tracy Evans Boutique Designs.

Thanks to this key business partnership, my small business runs efficiently, profitably and with strong values to ensure I offer a quality product and customer service to my customers, whom without I would not be here”.

Tracy Evans

“I’ve had the pleasure of working with Photocentric for around 10 years now, and they’ve consistently been a trusted partner in our business. From the beginning, their commitment to delivering the highest quality has been a key reason we chose, and continue, to work with them. Their quick turnaround times and a team that’s always ready to help made them stand out early on, and that level of service has never wavered.

We use their services to produce Clear Photopolymer Stamps and Mylar Stencils, and the products are always top quality – reliable, consistent, and beautifully finished. But just as important as the products is the team behind them. The support we receive is outstanding – knowledgeable, approachable, and always available when we need them.

Photocentric isn’t just a supplier to us – they’re a valued partner in our creative journey.”

Arden Creative

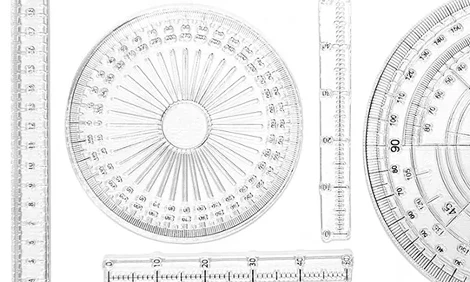

How we guarantee dimensional accuracy in your clear stamps

The process of making your stamps

Artwork to negative

Your artwork is created from your digital file, and this is transferred to a printer to create the negative and is an exact physical representation of it. It is accurate to the thou as we use the highest resolution large format printers on the market.

Negative to stamp

Light from the exposure beds hardens the photopolymer. All liquids shrink in the transition to solid (water being the only exception) and photopolymer shrinks by about 3% in volume as it polymerizes from liquid to solid.

In our process this takes place slowly and the liquid resin that surrounds the cured stamps replaces it. When the exposure is finished, the light through the negative will have hardened the liquid polymer to be an exact copy of the negative, and it is a dimensionally accurate representation.

How we test and prove this

We will run periodic test negatives through, one is a curved protractor measurement and the other a straight rule, covering both straight and curved accuracy. We make them into a stamp and then measure against the physical standard.