Ecosystem

Sustainable Manufacturing

Beyond Earth

CosmicMaker is being developed as a fully modular, scalable machine delivered complete with all hardware, materials and software development.

Autonomous Manufacturing Platform

Operating independently of both gravity and pressure, CosmicMaker is optimised for microgravity and harsh space conditions. Built on industry proven 3D printing technology that has made tens of millions of parts on Earth.

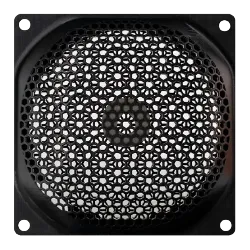

LCD Stereolithography

High-resolution prints, minimal

energy, simple reliable optics

Sealed Resin Vats

Safe easy to refill zero spill risk

Sensors & Monitoring

Digital control, physical twin on Earth

Compact Footprint

Rack-mountable module for

ISS and orbital labs

Advanced Materials

Broad range of materials with theoretically all thermosets and any sinterable material. Makes most ceramics, metals, thermoset plastics and composites.

Polymers

Radiation-tolerant photopolymers

All thermosets from elastomers to rigids

Composites

Polymer-fibre and particle composite polymers products

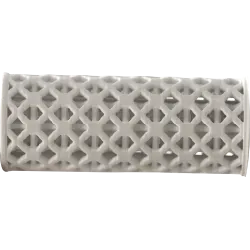

Ceramics

Silicon carbide, alumina, zirconia and other

Advanced industrial ceramics

Future Metals

Including oxidisable hard to laser sinter metals