Production Parts

We are no ordinary parts service.

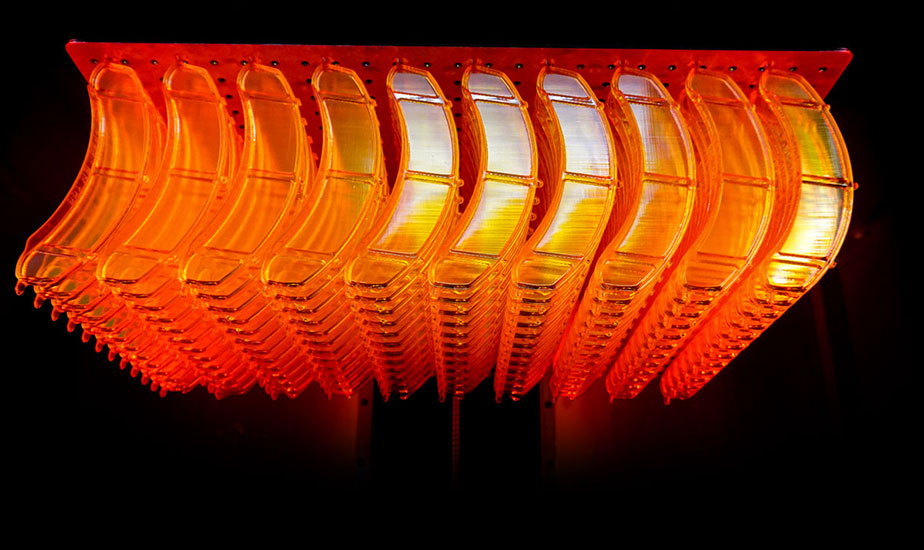

We invented an autonomous industrial mass manufacturing process. As a chemical, machine and parts manufacturer, we use our integration to provide exceptional value, turning liquid into solid in a volume never before possible.

Flexibility

Eliminate excess inventory & supply bottlenecks.

Speed To Market

Produce parts in days rather than months.

High Volumes

Produce tens of thousands of parts a day.

Digital Surfacing

Digital surfaces transform appearance

No Tooling

Eliminate expensive moulds.

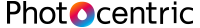

PCB Standoff – 6,000 parts

Creating the largest quantity of a single PPE item by 3D printing ever made

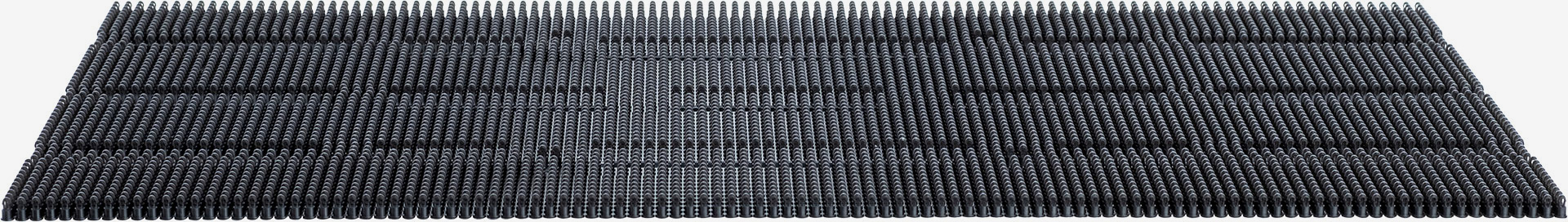

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

Creating the largest quantity of a single PPE item by 3D printing ever made

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

How do you get your parts?

Step 1

We discuss your requirements and design for additive manufacture.

Step 2

We select material properties and optimise the printing process.

Step 3

We manufacture your order and deliver it

Need Advice?

Talk to an expert.

From initial design through to despatch, we advise you on every part of the process. Our team have a huge amount of experience in CAD, Design For Additive, material and engineering properties.

Agustin

With significant experience gained in a variety of industries for large and small companies. Agustin touches every aspect of product development from chemistry, software, design and material science.

Sally

A wealth of knowledge gained over 25 years in polymers, 3D printing and manufacturing. Sally passionately believes in transforming industry with scalable and affordable Additive Manufacturing solutions.

Book a consultation.

For a no obligation consultation use the form below to secure your slot. Alternatively use our Contact form now.

Ready to go? Get a quote now.

Simply upload your STL or STEP file and we’ll get back in touch. Or to talk to one of our team just tick the call back option.

Warranty

All parts guaranteed

Secure Files

Your IP and data is protected

Quality Assured

Rigorous quality control

UK Manufactured

All parts manufactured in our UK facility

Energy Efficient

All of our power comes from renewable sources

A Commitment to Quality

A considerable investment has been made on developing detailed quality control procedures to ISO9001 throughout the production process to ensure a high level of customer satisfaction.

We are proud members of