3D printing solutions

Dental Models

Photocentric is a leading supplier of 3D printing processes to the dental industry.

Opus is the optimised solution for making high accuracy crown and bridge and surgical guides.

Magna is the workhorse of dental model production, one of the most reliable and widely used printers, making hundreds of thousands of dental models every year.

Bridge Dental Laboratory

3D printed technology to manufacture customised dental appliances with plant-based resins

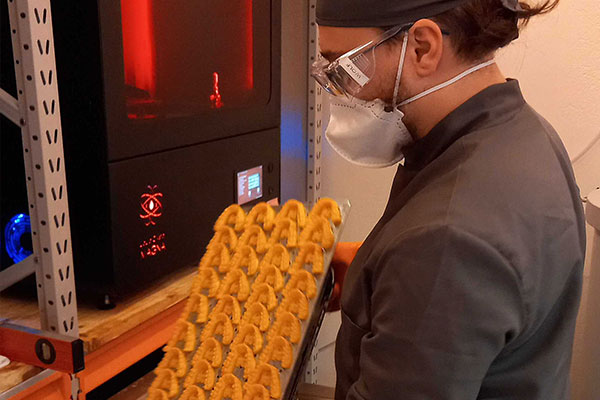

Bridge Dental specialises in pressure formed appliances, whitening trays and retainers, crown and bridge prosthetics, night guards and gumshields offering a full-service dental lab. They are changing patients’ lives by using advanced 3D printing technology to provide fast and affordable customised dental pieces.

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

Bridge Dental Laboratory

3D printed technology to manufacture customised dental appliances with plant-based resins

Bridge Dental specialises in pressure formed appliances, whitening trays and retainers, crown and bridge prosthetics, night guards and gumshields offering a full-service dental lab. They are changing patients’ lives by using advanced 3D printing technology to provide fast and affordable customised dental pieces.

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

“We look forward to seeing where our partnership with Photocentric takes us as they continue to transform the additive manufacturing landscape offering disruptive solutions for the dental sector.”

George Wheeler

Lab Manager Bridge Dental

SouSmile opts for Photocentric Liquid Crystal Magna 3D printer

SouSmile has invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce its dental aligners at scale.

As Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, SouSmile has sold over 5,000 cases since launching in November 2018 with 20% of customers coming through word-of-mouth. The 3D printing investment has allowed SouSmile to internalise production of its transparent aligners, making substantial cost savings whilst helping customers align their teeth at a fixed price in a straightforward and effective process.

*More than 2,000 customers

“We met Photocentric through an industry veteran and were very impressed not only by the solution they had to offer but also by the similarity in mindset”

Michael Ruah

Co-founder, SouSmile

SouSmile opts for Photocentric Liquid Crystal Magna 3D printer

SouSmile has invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce its dental aligners at scale.

As Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, SouSmile has sold over 5,000 cases since launching in November 2018 with 20% of customers coming through word-of-mouth. The 3D printing investment has allowed SouSmile to internalise production of its transparent aligners, making substantial cost savings whilst helping customers align their teeth at a fixed price in a straightforward and effective process.

*More than 2,000 customers

“We met Photocentric through an industry veteran and were very impressed not only by the solution they had to offer but also by the similarity in mindset”

Michael Ruah

Co-founder, SouSmile

Clear aligner enterprise

Photocentric are an approved 3Shape Clear Aligner Enterprise Technology Printer Partner. The partnership ensures a seamless journey from start to finish, compatibility with Photocentric software and printers, enabling you to produce high quality printed models consistently and efficiently.

Bridge Dental specialises in pressure formed appliances, whitening trays and retainers, crown and bridge prosthetics, night guards and gumshields offering a full-service dental lab. They are changing patients’ lives by using advanced 3D printing technology to provide fast and affordable customised dental pieces.

Providing quality and sustainable products is what Bridge Dental is all about. This 40-year-old family-owned dental laboratory produces appliances of the highest quality with a special focus on the environment. It is Bridge Dental’s number one priority to ensure that every patient is 100% happy with their appliance and that the processes and materials used are environmentally friendly.

Challenge

Each patient has a unique set of requirements. Producing affordable appliances that are suited to each individual without waste is challenging with traditional manufacturing.

The small SLA production batches that Bridge Dental were running were unsuitable for mass manufacture. They needed to scale up production using bigger build volumes.

The digitisation of the dental industry has been driven by the innovation and 3D printing technologies, with Photocentric at the forefront of this development as manufacturers of photopolymer resins, 3D printers and production parts.

Solution

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

A key characteristic of DL240 Plant-Based is its translucency, this cuts down its post cure time by over 60% in turn saving vast quantities of energy and making the process much quicker. This fits perfectly into Bridge Dental’s workflow preventing downtime.

The fleet of Liquid Crystal Magna and Opus printers combined with the multi-printer DL240 Plant-Based resin compatible for both UV and Daylight, enables Bridge Dental to vastly reduce inventory costs and continually reinvest in other areas of their business.

SouSmile opts for Photocentric Liquid Crystal Magna 3D printer

SouSmile has invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce its dental aligners at scale. As Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, SouSmile has sold over 5,000 cases since launching in November 2018 with 20% of customers coming through word-of-mouth. The 3D printing investment has allowed SouSmile to internalise production of its transparent aligners, making substantial cost savings whilst helping customers align their teeth at a fixed price in a straightforward and effective process.

Challenge

“The Brazilian aligner market is relatively nascent and highly regulated, which made it difficult to procure high quality aligners at scale,” says Michael Ruah, co-founder, SouSmile. “That’s why we decided to invest in automated production early on. The challenge was finding industrial-scale printers at a reasonable price.

Solution

SouSmile’s cost per part fell 30% when it internalised production with the LC Magna, which is equivalent to about US $60k in monthly savings, or US $720k per year. More than 2,000 customers have finished orthodontic treatment at SouSmile, with a satisfaction rate of 4.87 out of 5 stars. The company is vertically integrated with an automated production facility that now has capacity to produce 1,500 aligners per day with three printers.

“We got quotes and tested almost every printer in the market for dental applications and no one matched the cost benefit. Photocentric LC Magna was the only printer we analysed that could produce 48 models in 90 minutes. The Magnas are extremely fast, accurate and have a great cost-benefit for both hardware and resin. No one else came even close.”

“There are huge opportunities for 3D printing in many sectors, and SouSmile has clearly made a shrewd investment in adopting 3D printing technology to enhance its dental aligner offering,” says Sally Tipping, Sales Director, Photocentric.