Case Studies

Learn how our technology, in operation in over 40 countries, is changing the way companies operate

All

Dental

Automotive

Arts & Models

Medical

Manufacturing

Consumer Goods

Girbau

Girbau, a manufacturer of equipment for laundry services, sought to improve the efficiency of their folding machines. They optimised the air flow with Photocentric’s advice on design for additive and delivered a product improvement cost-effectively with the Liquid Crystal Magna.

Grisport

Founded in 1977, Grisport is one of the leading companies in direct injection and shoemaking worldwide. They chose the Liquid Crystal Magna because it is one of the largest printers of its kind, it’s cost effective and very fast.

Crack Eraser

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser.

Micron Sprayers

Our UK partner 3D GBIRE and Micron Sprayers, a leading manufacturer of specialist agricultural sprayers, produced this video, showing how Micron moved from FDM printing to custom mass manufacturing with the Liquid Crystal Magna.

Phone Skope

Phone Skope is a US manufacturer of precision engineered adaptors for almost any smartphone and has adopted the Liquid Crystal Magna as the solution to making lots of its custom-moulded digiscoping adaptors.

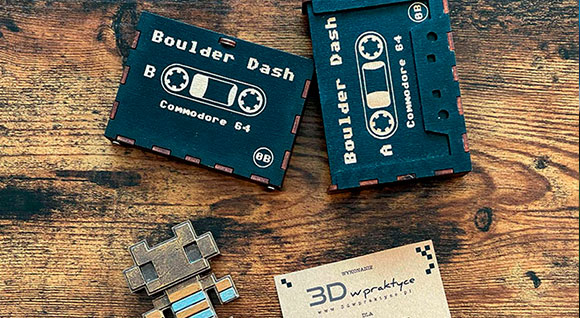

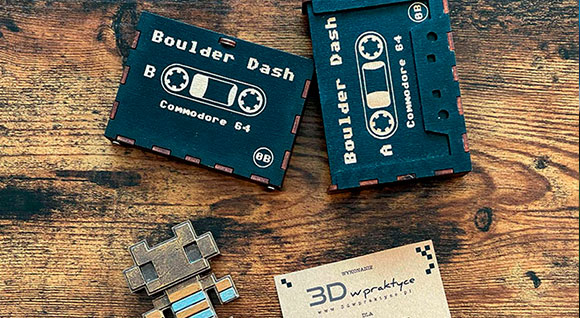

3D w praktyce

As an homage to this classic game, 3D w praktyce were tasked with creating a short stop-frame animation. For this animation, a 3D print-ready file of the character Rockford was created using Photocentric Studio which was then printed on the LC Magna.

cirp

In Germany, cirp, a 3D Printing Bureau were approached by modellbahn.blog, a specialist online model railway retailer that offers service and a wide range of spares and accessories to model railway enthusiasts. Learn how they used Liquid Crystal Magna

Smilelign & S4S

Smilelign and S4S, major players in the UK dental aligner market, had tried almost every manufacturer of 3D printers to meet their requirements for both reliability and productivity before deciding upon Liquid Crystal Magna.

Tetralogia

Providing quality moulds to advanced manufacturers in the metalworking industry for a variety of

applications is the core business of Tetralogia’s customer. They were looking for a solution that could

shorten lead times and save manufacturing costs

Sousmile

SouSmile is Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, they invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce their dental aligners in scale.

XKelet

The powerful alliance of Xkelet and Photocentric has created a new solution to traditional orthotics; a digital 3D printed splint that provides significant benefits over traditional methods and is revolutionising the treatment of damaged bones.

3D Next Level

3D Next level is a business that creates large-scale pieces for art applications using additive manufacturing technologies to create investment casting patterns for art pieces and transformed their business with the Liquid Crystal Magna.

Merit3D

Merit3D, a leading additive manufacturing company, is producing 1,000,000 hangers for Adhesives Technology using 3D printing technology. The hangers are required for every project Adhesives’ undertakes, but the production process was halted due to the unavailability of the injection mould tool.

Bridge Dental

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

NHS

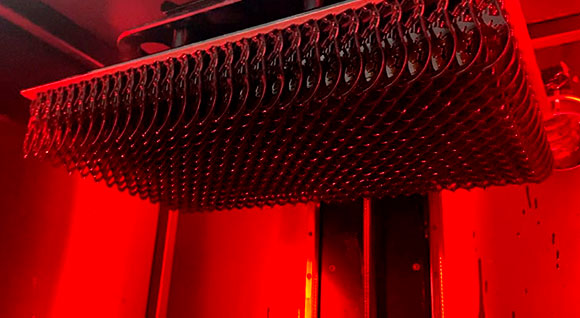

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

Smilelign & S4S

Smilelign and S4S, major players in the UK dental aligner market, had tried almost every manufacturer of 3D printers to meet their requirements for both reliability and productivity before deciding upon Liquid Crystal Magna.

Bridge Dental

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

Sousmile

SouSmile is Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, they invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce their dental aligners in scale.

Crack Eraser

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser.

cirp

In Germany, cirp, a 3D Printing Bureau were approached by modellbahn.blog, a specialist online model railway retailer that offers service and a wide range of spares and accessories to model railway enthusiasts. Learn how they used Liquid Crystal Magna

3D Next Level

3D Next level is a business that creates large-scale pieces for art applications using additive manufacturing technologies to create investment casting patterns for art pieces and transformed their business with the Liquid Crystal Magna.

3D w praktyce

As an homage to this classic game, 3D w praktyce were tasked with creating a short stop-frame animation. For this animation, a 3D print-ready file of the character Rockford was created using Photocentric Studio which was then printed on the LC Magna.

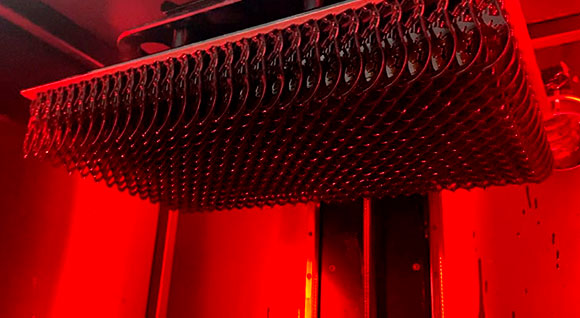

NHS

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

XKelet

The powerful alliance of Xkelet and Photocentric has created a new solution to traditional orthotics; a digital 3D printed splint that provides significant benefits over traditional methods and is revolutionising the treatment of damaged bones.

Girbau

Girbau, a manufacturer of equipment for laundry services, sought to improve the efficiency of their folding machines. They optimised the air flow with Photocentric’s advice on design for additive and delivered a product improvement cost-effectively with the Liquid Crystal Magna.

Micron Sprayers

Our UK partner 3D GBIRE and Micron Sprayers, a leading manufacturer of specialist agricultural sprayers, produced this video, showing how Micron moved from FDM printing to custom mass manufacturing with the Liquid Crystal Magna.

Grisport

Founded in 1977, Grisport is one of the leading companies in direct injection and shoemaking worldwide. They chose the Liquid Crystal Magna because it is one of the largest printers of its kind, it’s cost effective and very fast.

Tetralogia

Providing quality moulds to advanced manufacturers in the metalworking industry for a variety of

applications is the core business of Tetralogia’s customer. They were looking for a solution that could

shorten lead times and save manufacturing costs

Merit3D

Merit3D, a leading additive manufacturing company, is producing 1,000,000 hangers for Adhesives Technology using 3D printing technology. The hangers are required for every project Adhesives’ undertakes, but the production process was halted due to the unavailability of the injection mould tool.

Phone Skope

Phone Skope is a US manufacturer of precision engineered adaptors for almost any smartphone and has adopted the Liquid Crystal Magna as the solution to making lots of its custom-moulded digiscoping adaptors.